The safety laser scanner’s internal configuration memory is integrated in the system

plu

g. The system plug and all connecting cables can remain at the installation site

when the safety laser scanner is replaced. The system plug is detached from the

defective safety laser scanner and connected to the new safety laser scanner. The

new safety laser scanner reads the configuration from the configuration memory when

switching on.

4.2.6 Field types

During operation, the safety laser scanner uses its laser beams continuously to check

whe

ther people or objects are present in one or more areas. The areas to be checked

are called fields. A distinction is made between the following field types, depending on

how the safety laser scanner is used:

•

Protective field

•

Reference contour field

•

Contour detection field

•

Warning field

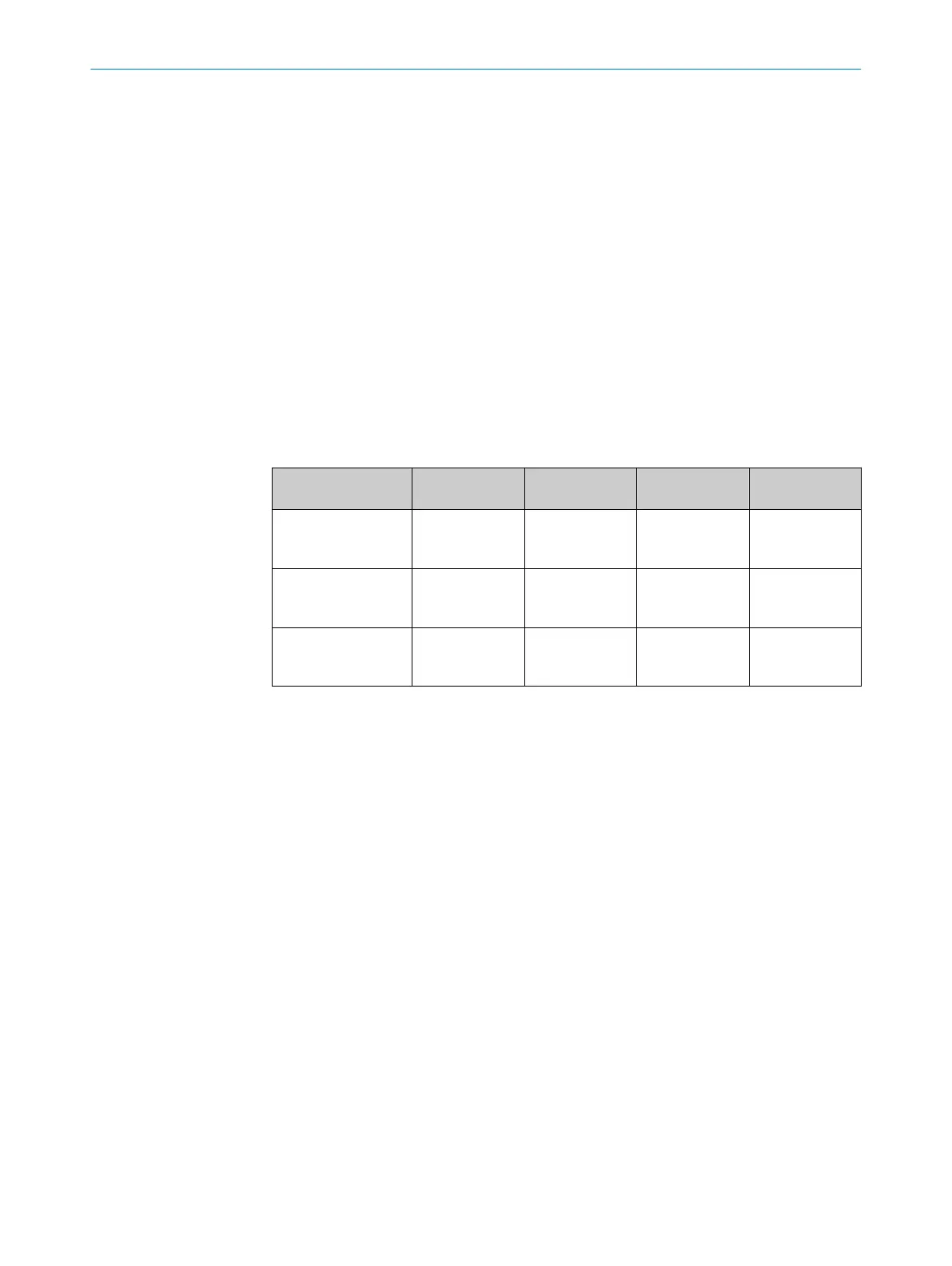

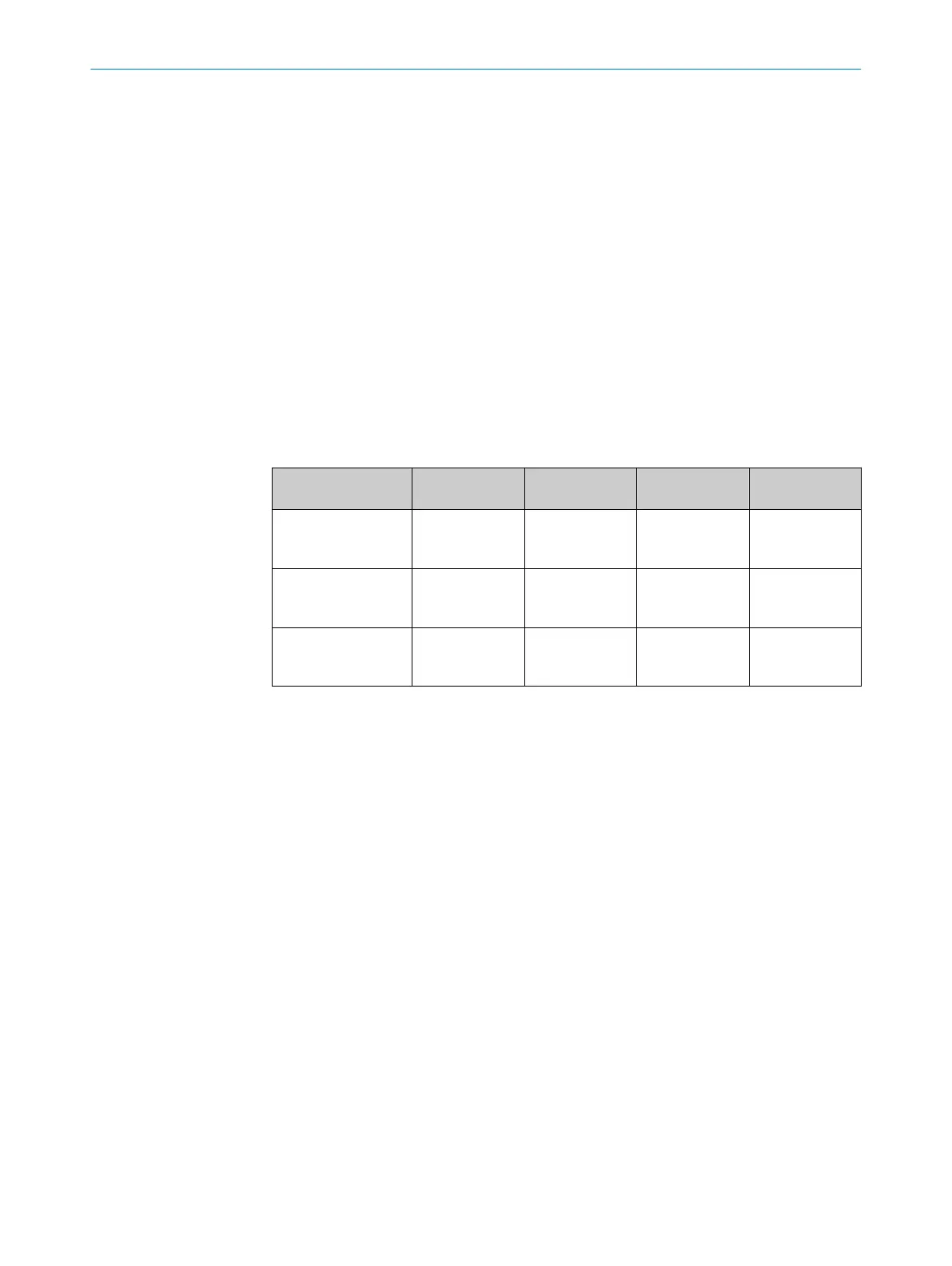

Table 4: Field types and their function

Protective field Reference con‐

t

our field

Contour detec‐

tion field

Warning field

Safe switch off

(according to ISO

13849-1)

Yes (PL d) Yes (PL d) Yes (PL d) No

Max. scanning range

of the safety laser

scanner

5.5 m 5.5 m 5.5 m 40 m

Purpose Detection and

pr

otection of

people

Tamper protec‐

tion

e.g. door moni‐

toring

Functional use

(no safety-rele‐

vant use)

Protective field

T

he protective field protects the hazardous area of a machine or vehicle. As soon as the

electro-sensitive protective device detects an object in the protective field, it switches

the associated safety outputs to the OFF state. This signal can be passed to controllers

resulting in the dangerous state coming to an end, e.g. to stop the machine or the

vehicle.

4 P

RODUCT DESCRIPTION

18

O P E R A T I N G I N S T R U C T I O N S | microScan3 Core I/O 8025870/2020-09-04 | SICK

Subject to change without notice

Loading...

Loading...