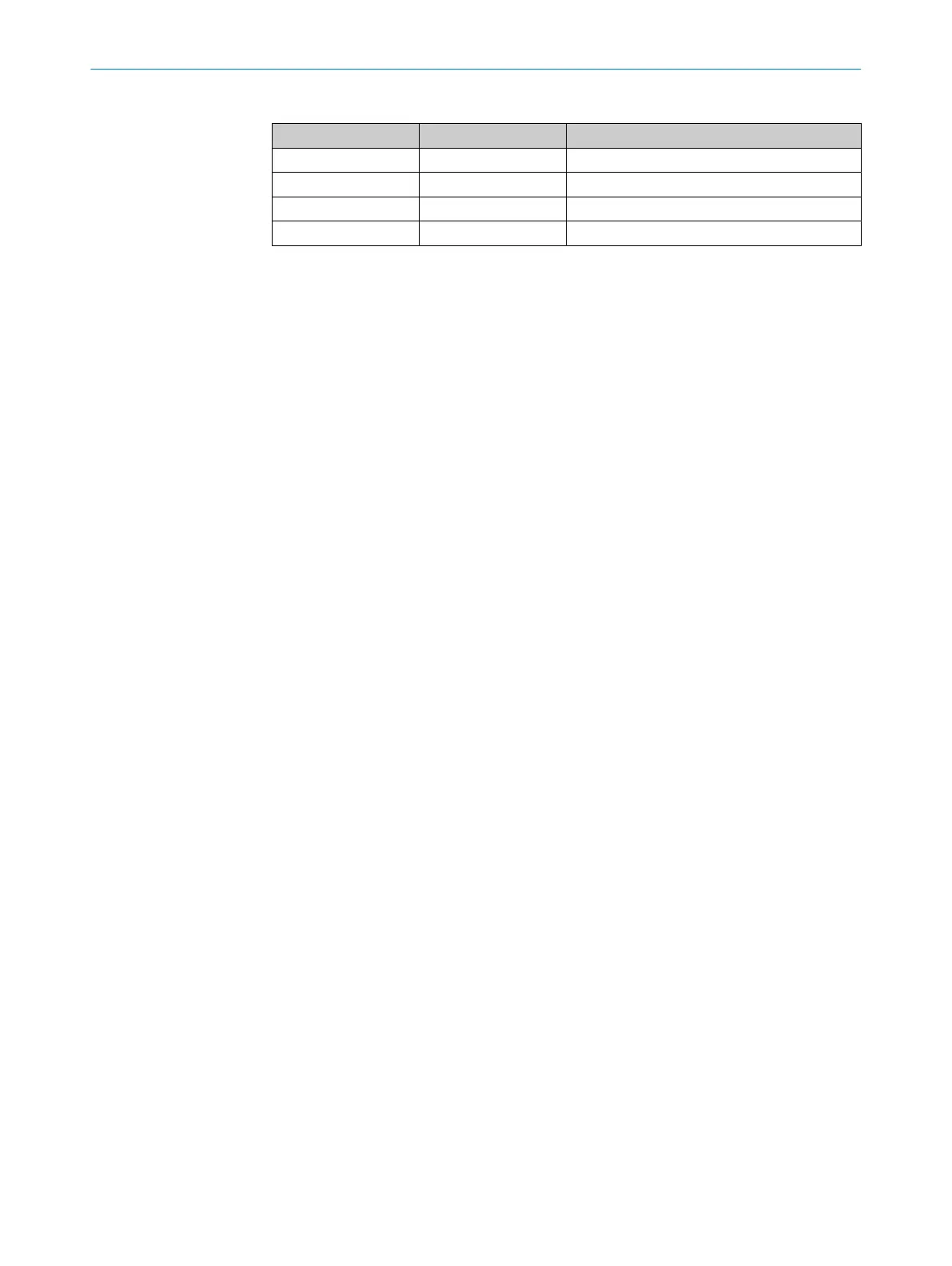

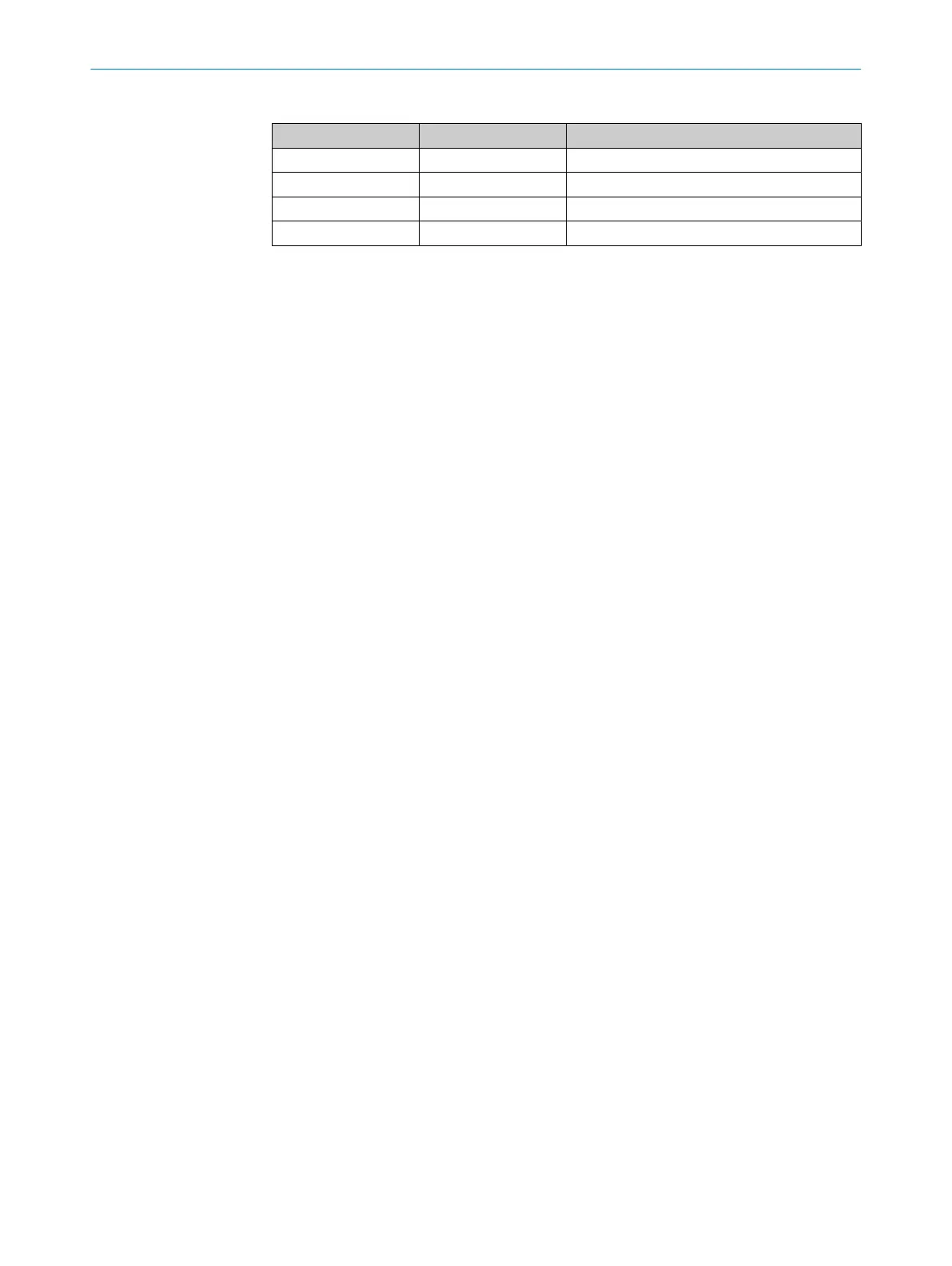

Table 5: Status of the channels of the control inputs with complementary evaluation

A1 A2 Logical input status (input A)

1 0 0

0 1 1

1 1 Fault

0 0 Fault

In antivalent evaluation, the 2 channels of each static control input must always be

in

verted, even if the status of a control input in a monitoring case is random. If it is not

inverted, all safety outputs switch to the OFF state and the device displays a fault.

5.4.5 Universal inputs, universal outputs, universal I/Os

The safety laser scanner is equipped with universal I/Os.

U

niversal I/O can be configured as universal input or as universal output.

Depending on the device, a universal input can be used for resetting, external device

monitoring (EDM), sleep mode, or restarting the protective device, for example. If sleep

mode is activated by a universal input, the sleep mode must not be used for safety

applications. Certain universal inputs can also be used in pairs as a static control input.

A universal output outputs a signal depending on its configuration, e.g. if the reset

pushbutton needs to be pushed or if the optical cover is contaminated. A universal

output must not be used for safety functions.

b

Use the same earthing method for all devices that are electrically connected to the

safety laser scanner.

b

Voltage must be supplied in accordance with SELV/PELV (IEC 60204-1) for all

devices that are electrically connected to the safety laser scanner.

b

All devices that are electrically connected to the safety laser scanner must be

supplied by the same voltage supply.

Information about electrical properties: see "Technical data", page 142

Information about pin assignment: see "Electrical installation", page 69

5.4.6 Restart interlock

Depending on the regulations which apply at the place of installation, a restart interlock

ma

y be required.

The restart interlock prevents the machine from automatically starting up, for example

after a protective device has responded while the machine is operating or after chang‐

ing the machine’s operating mode.

First, the operator must press a reset pushbutton to return the protective device to

monitoring status. Then, in a second step, the operator can restart the machine.

Depending on applicable national regulations, a restart interlock must be available if it

is possible to stand behind the protective field.

Reset

T

he reset brings the protective device back to the monitoring state after it has sent

a stop command. The reset also quits the start-up or restart interlock of a protective

device, so that the machine can be restarted in a second step.

The reset must only be possible, when all safety functions and protective devices are

functional.

5 PROJECT PLANNING

56

O P E R A T I N G I N S T R U C T I O N S | microScan3 Core I/O 8025870/2020-09-04 | SICK

Subject to change without notice

Loading...

Loading...