9 Operation

9.1 Safety

DANGER

H

azard due to lack of effectiveness of the protective device

Persons and parts of the body to be protected may not be recognized in case of

non-observance.

b

Maintenance work, alignment work, fault diagnoses, and any changes to the

integration of the protective device in the machine must only be carried out by

qualified personnel.

b

The effectiveness of the protective device must be checked following such work.

NOTE

T

his document does not provide instructions for operating the machine in which the

safety laser scanner is integrated.

9.2 Regular thorough check

The test is intended to ensure that the hazardous area is monitored by the protective

de

vice and any attempted access to the hazardous area is prevented.

b

Carry out the checks specified in the test plan of the manufacturer of the machine

and the operating entity.

9.3 Status indicators

Overview

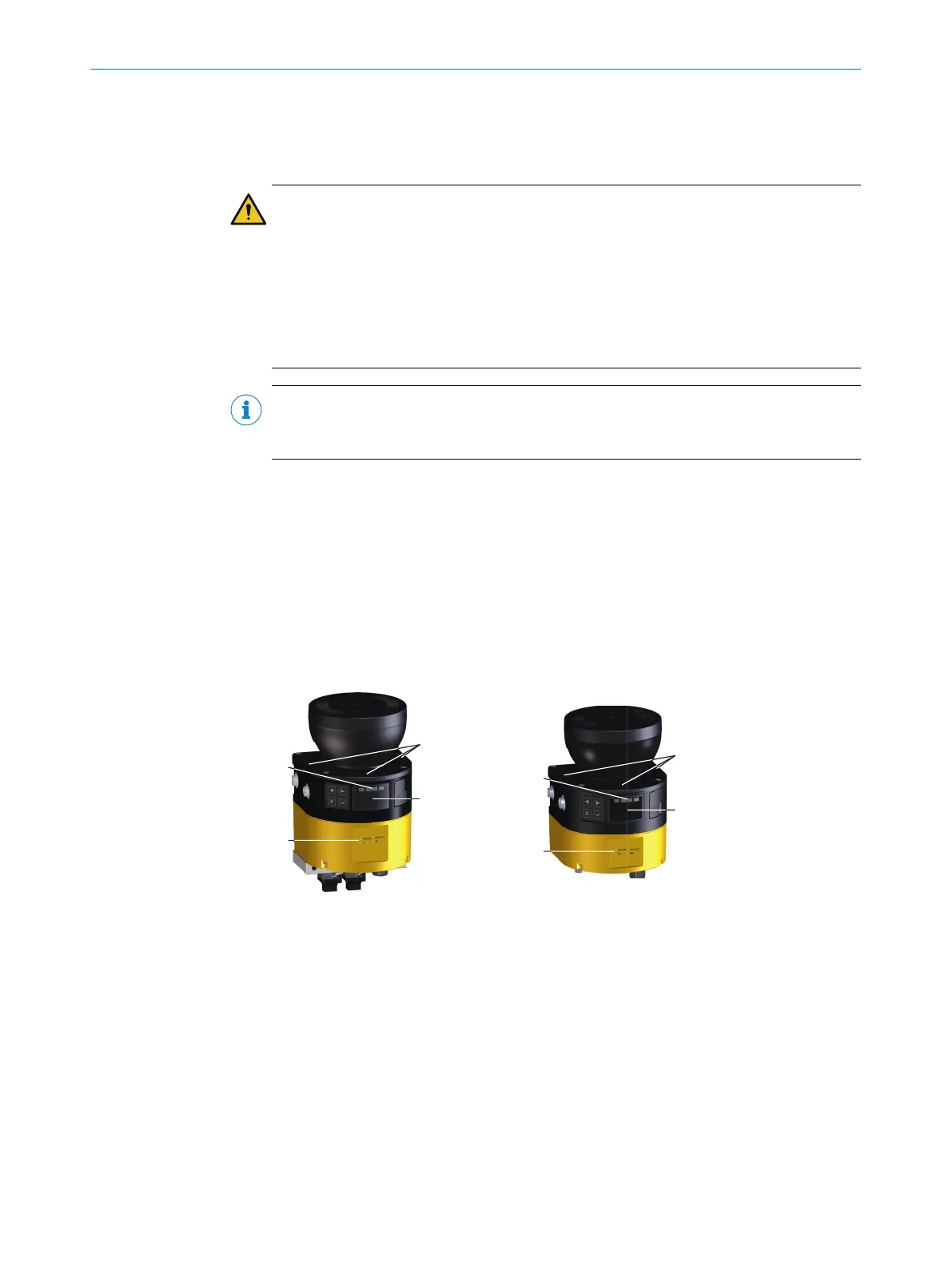

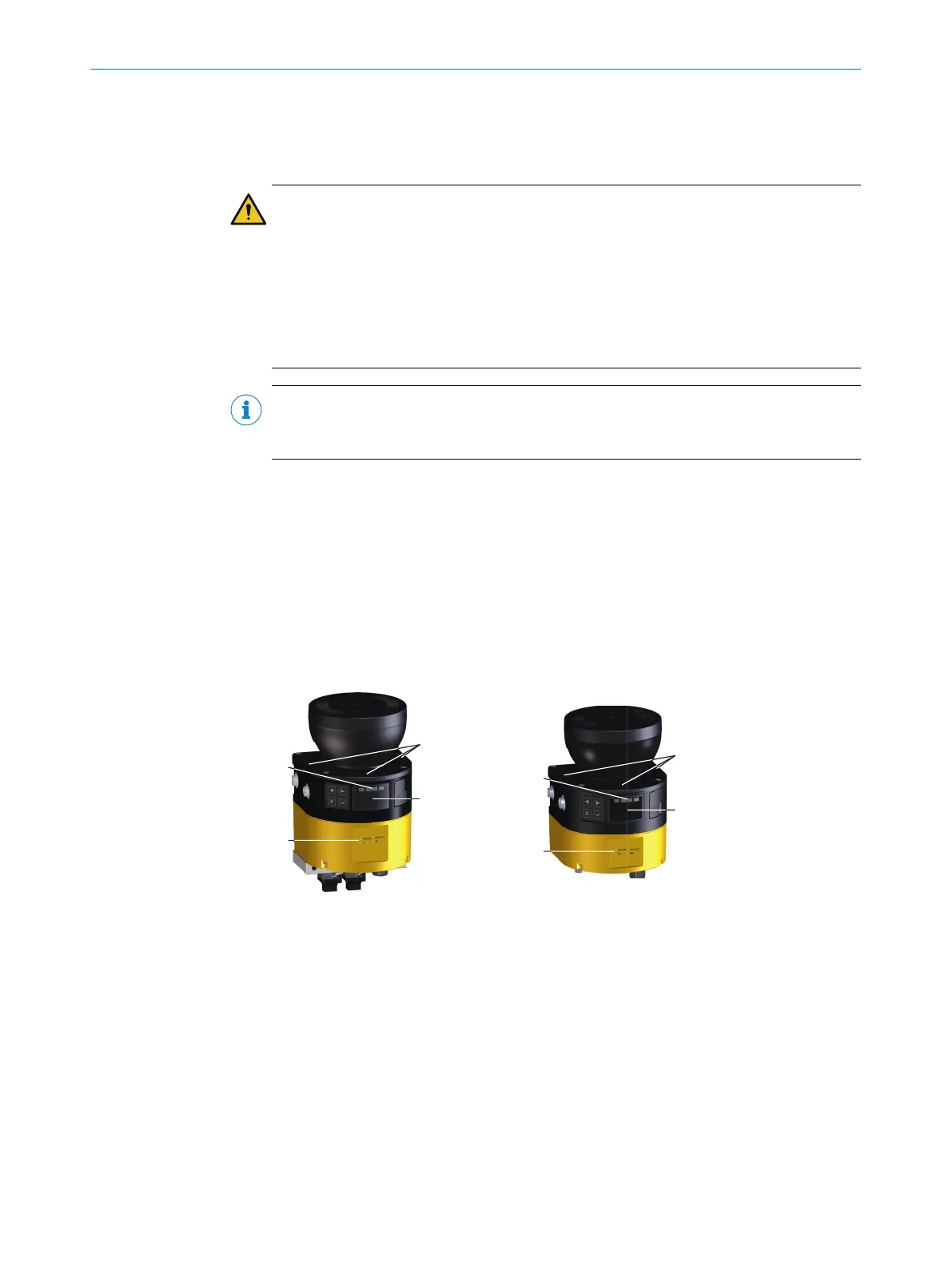

Figure 82: LEDs (

left: microScan3 – PROFINET (RJ45 / SCRJ), right: microScan3 – PROFINET

(M12))

1

Status LEDs

2

Additional LEDs for ON state and OFF state

3

Display

4

Network LEDs

Further topics

•

"D

etailed diagnostics using the display", page 149

•

"Fault indication on the display", page 151

9.3.1 Status LEDs

4 status LEDs are located directly above the display.

9 O

PERATION

136

O P E R A T I N G I N S T R U C T I O N S | microScan3 – PROFINET 8021219/1ELL/2022-01-21 | SICK

Subject to change without notice

Loading...

Loading...