7. Install the cover plate on the safety laser scanner. Tightening torque: 2.25 Nm …

2.75 Nm.

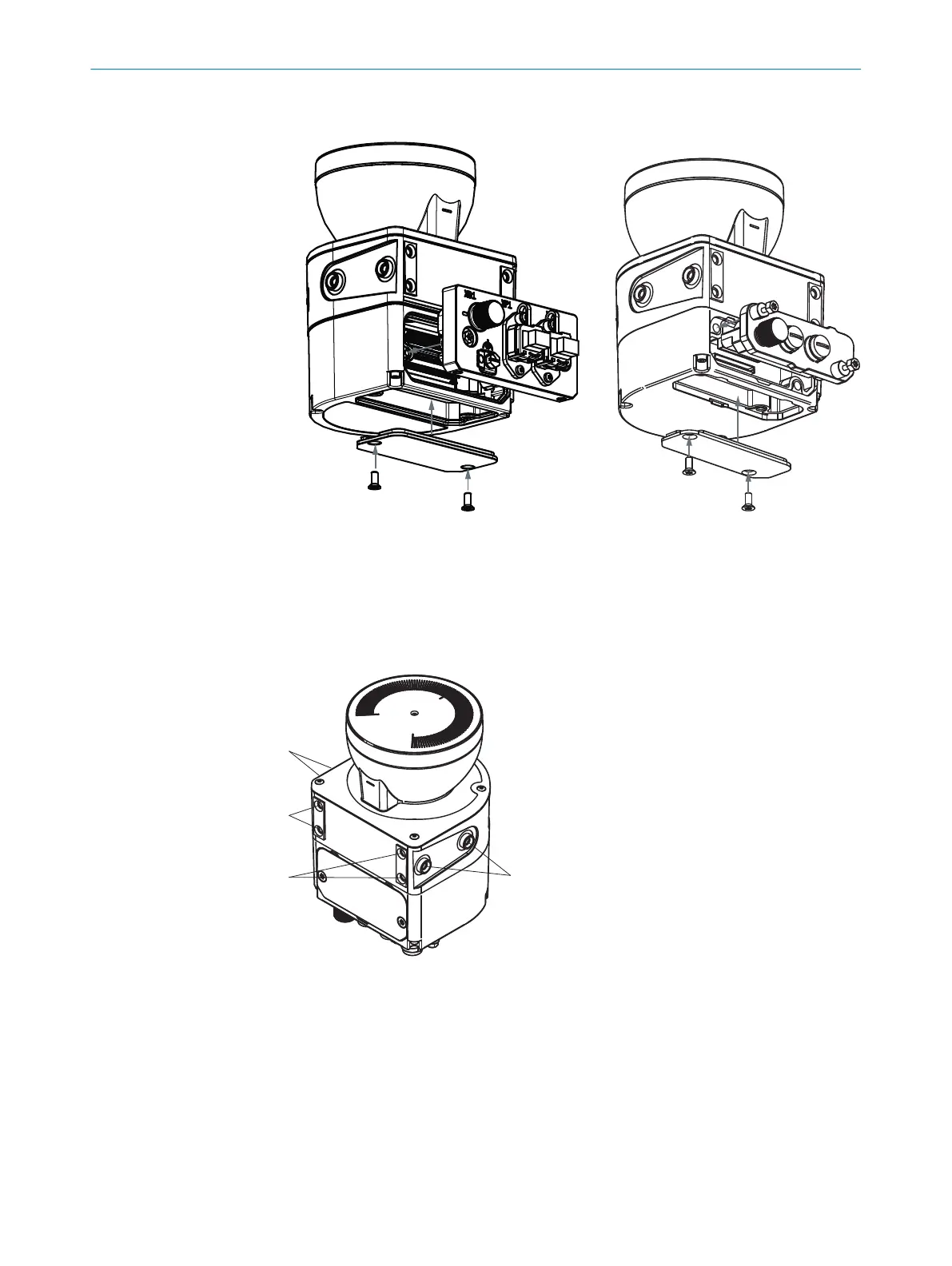

Figure 49: Installing the rear system plug (left: microScan3 – PROFINET (RJ45 / SCRJ),

right: microScan3 – PROFINET (M12))

5.3.2 Direct mounting

The safety laser scanner has 4 M5 threaded holes on the back. If you are able to drill

t

hrough the mounting surface from the rear, you can mount the safety laser scanner

directly using these threaded holes.

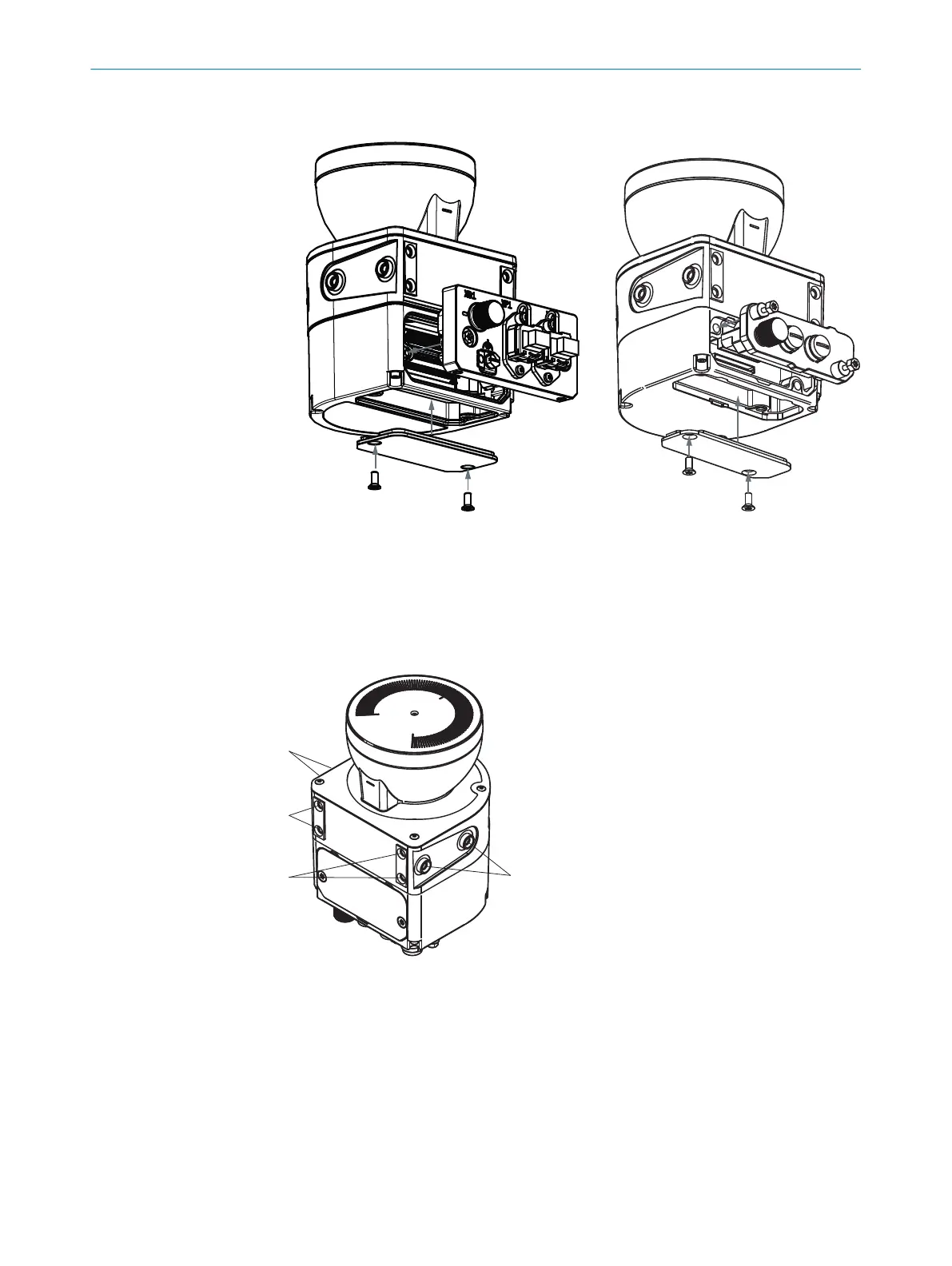

Figure 50: Mounting the safety laser scanner directly

1

Rear M5 threaded hole

2

Side M5 threaded hole

b

Use eit

her the rear or the side M5 threaded holes for direct mounting, see

figure 50, page 80.

b

Use all four rear or all 4 side M5 threaded holes for direct mounting, so that the

values given in the data sheet for vibration and shock resistance are achieved.

b

Maximum depth of thread engagement: 7.5 mm (see "Dimensional drawings",

page 187).

b

Tightening torque: 4.5 Nm to 5.0 Nm.

5 MOUNTING

80

O P E R A T I N G I N S T R U C T I O N S | microScan3 – PROFINET 8021219/1ELL/2022-01-21 | SICK

Subject to change without notice

Loading...

Loading...