3. If necessary: move the safety laser scanner to a clean location.

4.

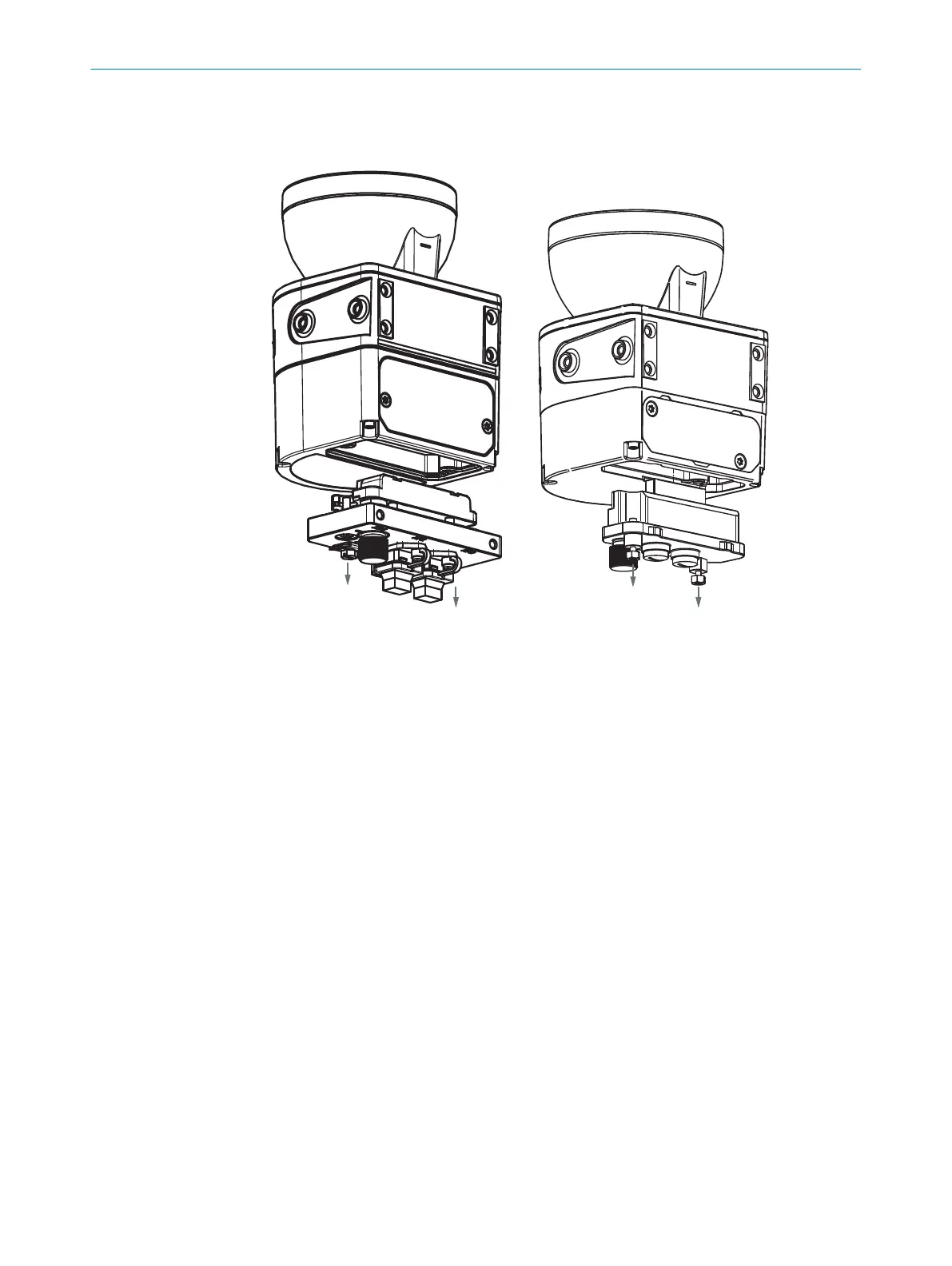

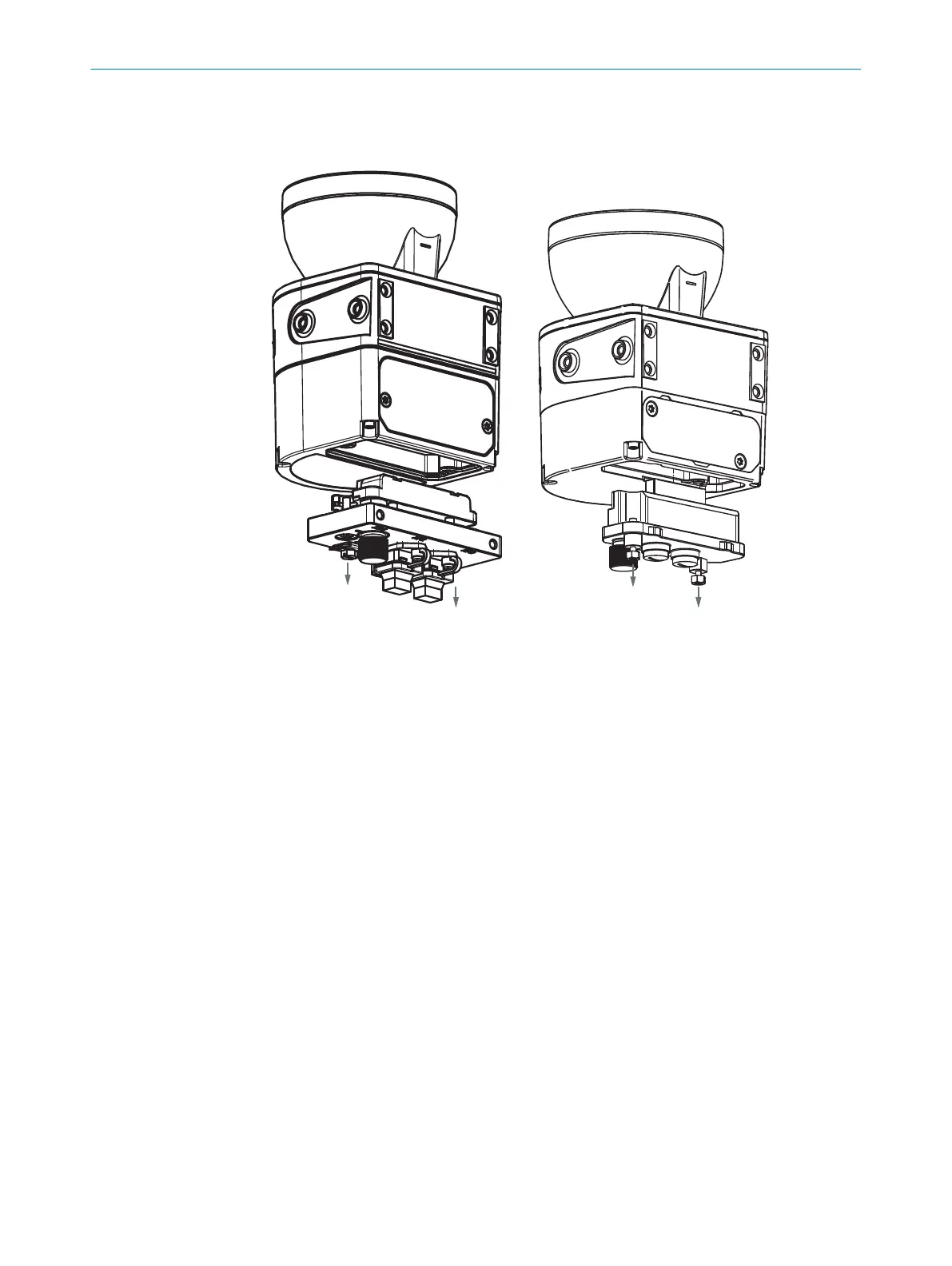

Unscrew the screws in the defective system plug and remove the system plug from

the safety laser scanner.

Figure 86: Replacing the system plug (left: microScan3 – PROFINET (RJ45 / SCRJ), right:

microScan3 – PROFINET (M12))

5. Carefully insert the new system plug into the safety laser scanner.

6. Screw in the system plug using the captive screws. Tightening torque: 2.25 Nm …

2.75 Nm.

7. Reconnect the connecting cables to the system plug.

8. Configure the safety laser scanner, see "Configuration", page 85.

9. Perform commissioning again, taking particular care to conduct all of the thorough

checks described, see "Commissioning", page 133.

Complementary information

If a s

ystem plug has already been used on a device that has a different interface for

integrating it into the controller, this system plug can no longer be used on a PROFINET

device.

10.6 Regular thorough check

The test is intended to ensure that the hazardous area is monitored by the protective

de

vice and any attempted access to the hazardous area is prevented.

b

Carry out the checks specified in the test plan of the manufacturer of the machine

and the operating entity.

10 M

AINTENANCE

148

O P E R A T I N G I N S T R U C T I O N S | microScan3 – PROFINET 8021219/1ELL/2022-01-21 | SICK

Subject to change without notice

Loading...

Loading...