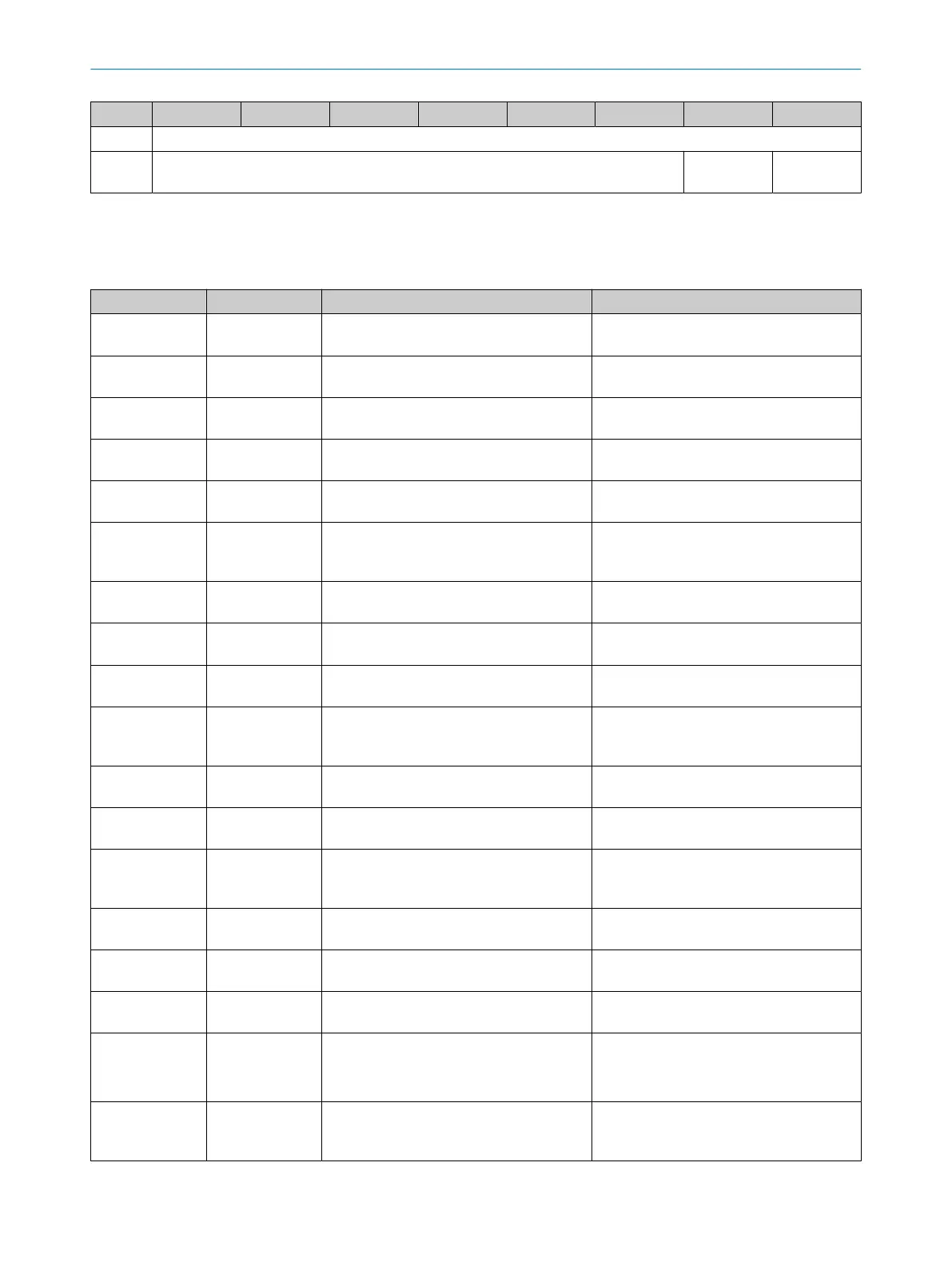

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

4 CurrentMonitoringCaseNoTable1

5 Reserved DeviceError Applicatio‐

nEr

ror

1)

Cut-off paths 5 to 8 are only available for the Pro performance package.

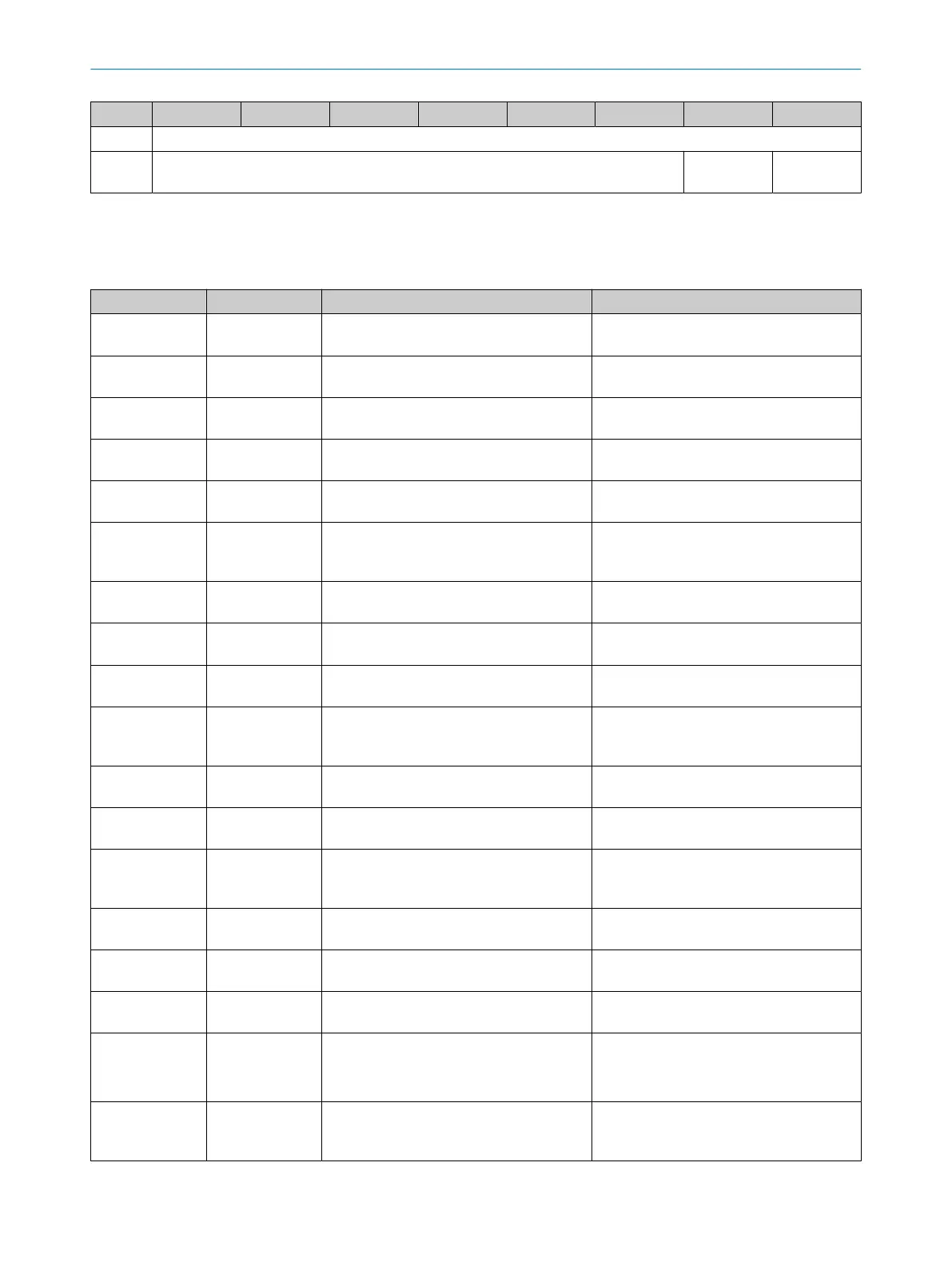

13.6.2 Alarms

Table 57: Available alarms (degree of difficulty: need for maintenance)

Number Severity Description Troubleshooting

64 Error Incorrect F destination address

(F_D

est_Add) set

b

Chec

k the PROFIsafe parameters of the

module.

65 Error Invalid F destination address (F_Dest_Add)

se

t

b

Chec

k the PROFIsafe parameters of the

module.

66 Error Invalid or incorrect F source address

(F_S

ource_Add) set

b

Chec

k the PROFIsafe parameters of the

module.

67 Error The fail-safe monitoring time (F_WD_Time)

is se

t to an invalid value of 0 ms

b

Chec

k the PROFIsafe parameters of the

module.

68 Error The set parameter F_SIL exceeds the

s

afety integrity level (SIL) of the device

b

Chec

k the PROFIsafe parameters of the

module.

69 Error The set parameter F_CRC_Length does not

ma

tch the length of the received CRC val‐

ues

b

Chec

k the PROFIsafe parameters of the

module.

70 Error F parameter version set incorrectly

b

Check the PROFIsafe parameters of the

module.

71 Error Inconsistent F parameter block received

(CR

C1 error)

b

R

ebuild and load the safety program.

72 Error Device-specific or unspecified diagnostic

me

ssage

75 Error iParameter inconsistent (F_iPar_CRC error)

b

Chec

k the set F_iPar_CRC.

b

Process image without checking the

F_iPar_CRC.

76 Error F_Block_ID not supported

b

Check the PROFIsafe parameters of the

module.

77 Error PROFIsafe transmission error: data incon‐

sis

tent (CRC2 error)

b

Chec

k wiring for damage and possible

electromagnetic interference (EMC).

78 Error PROFIsafe transmission error: Monitor‐

in

g time (F_WD_Time or F_WD_Time_2

expired)

b

Incr

ease, if necessary, the watchdog

time set in the PROFIsafe parameters.

256 Need for mainte‐

nance

Error in the application of the safety laser

sc

anner

b

Chec

k the configuration, control and

process of the machine.

257 Need for mainte‐

nance

Internal error in the safety laser scanner

b

R

estart device.

b

Replace the safety laser scanner.

258 Need for mainte‐

nance

Contamination warning

b

Check the optics cover for damage.

b

Clean the optics cover.

259 Need for mainte‐

nance

Contamination error All safety outputs in the OFF state.

b

Chec

k the optics cover for damage.

b

Clean the optics cover.

260 Need for mainte‐

nance

Tamper protection (reference contamina‐

tion field)

The safety laser scanner does not detect

a contour in the set tolerance band. All

safety outputs in the OFF state.

TECHNICAL DATA 13

8021219/1ELL/2022-01-21 | SICK O P E R A T I N G I N S T R U C T I O N S | microScan3 – PROFINET

185

Subject to change without notice

Loading...

Loading...