Advanced commissioning

6.6 Protection functions

Converter with the CU240B-2 and CU240E-2 Control Units

Operating Instructions, 01/2016, FW V4.7 SP6, A5E34259001B AC

271

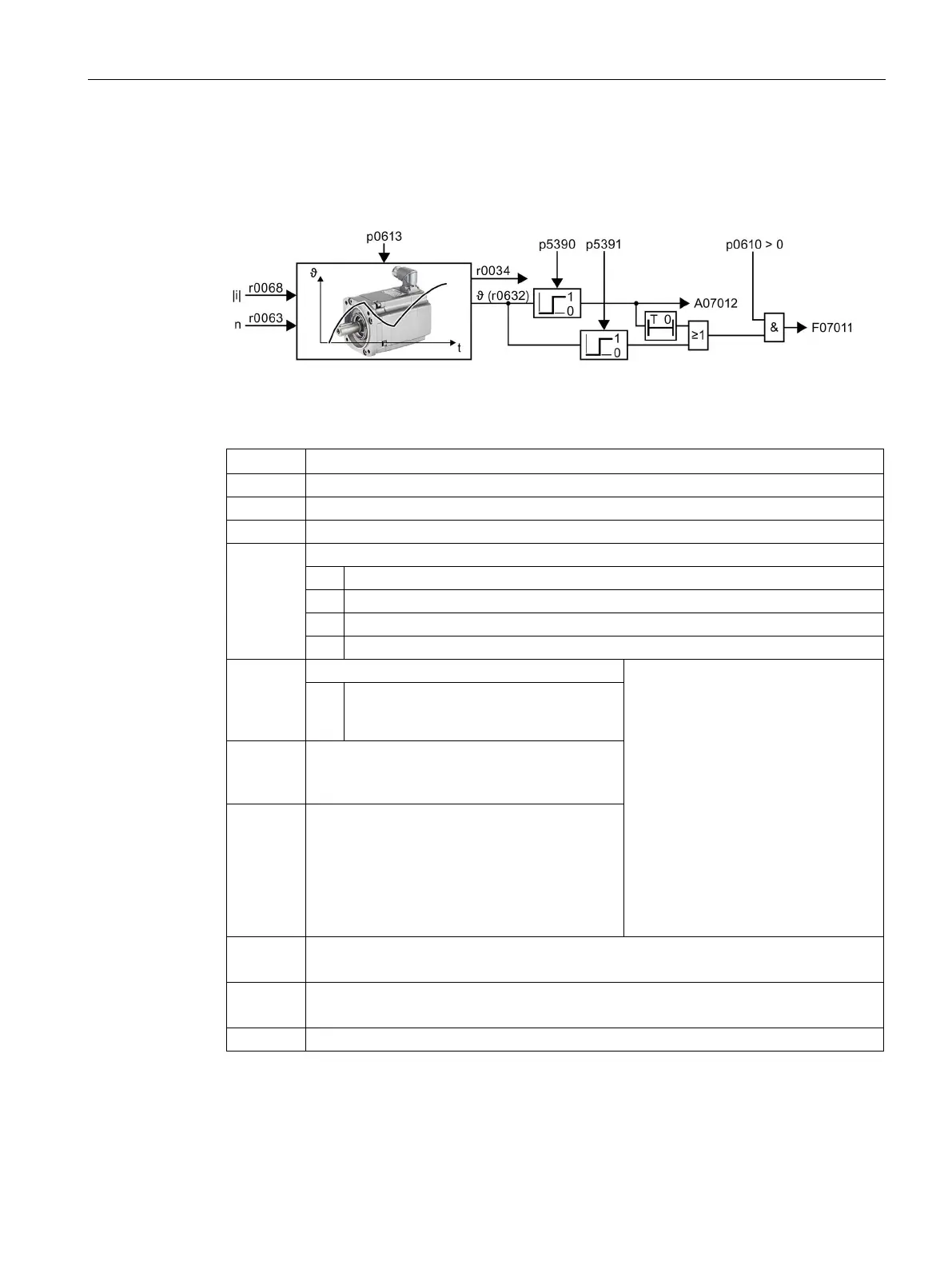

Thermal motor model 3 for encoderless synchronous motors

The thermal motor model 3 for encoderless synchronous motors 1FK7 or 1FG1 is a thermal

3-mass model, consisting of stator core, stator winding and rotor.

Image 6-44 Thermal motor model 3 for 1FK7 encoderless synchronous motors

Table 6- 38 Thermal motor model 3 for 1FK7 encoderless synchronous motors

CO: Thermal motor load [%]

CO: Actual speed value [rpm]

CO: Actual current value [A]

p0610

Motor overtemperature response (factory setting: 12)

No response, alarm only, no reduction of I

max

max

Messages, no reduction of I

max

Messages, no reduction of I

max

p0612

After selecting an encoderless syn-

chronous motor 1FK7 or 1FG1 (p0300)

or a listed induction motor (p0301)

during the commissioning, the inverter

sets thermal motor model 3 and the

parameters to values appropriate for

the motor type.

The parameters are write-protected for

listed motors (p0301 ≥ 0).

.02 1 signal: Activate motor temperature

model 3 for 1FK7 or 1FG1 encoderless

p5390

Mot_temp_mod 1/3 alarm threshold

(factory

setting: 110.0° C)

Motor temperature > p5390 ⇒ alarm A07012.

p5391

Mot_temp_mod 1/3 fault threshold

(factory

setting: 120.0° C)

Motor temperature > p5391

or

motor temperature > p5390, longer than a mo-

tor-dependent time calculated by the inverter

p0613

Mot_temp_mod 1/3 ambient air temperature

(factory setting: 20° C)

Expected motor ambient temperature in °C for motor operation.

p0625

Motor ambient temperature during commissioning

(factory setting: 20° C)

Motor ambient temperature in °C at the instant of the motor data identification.

Mot_temp_mod stator winding temperature [°C]

Further information is provided in the function charts 8016 and 8017 of the List Manual.

Loading...

Loading...