Advanced commissioning

6.7 Application-specific functions

Converter with the CU240B-2 and CU240E-2 Control Units

318 Operating Instructions, 01/2016, FW V4.7 SP6, A5E34259001B AC

The load monitoring comprises the following components:

● Load failure monitoring

● Monitoring for torque deviation

● Speed deviation monitoring

● Pump monitoring

● Fan monitoring

If the load monitoring detects load failure, then the inverter always goes into a fault condition

and outputs fault F07936. For a torque and speed deviation, as response, you can either set

an alarm or a fault. Details are provided in the following descriptions.

Table 6- 45 Setting options for load monitoring

p2193

Load monitoring configuration

(factory setting: 1)

0: Monitoring deactivated

1: Torque and load failure monitoring

2: Speed deviation and load failure monitoring

3: Monitoring, load failure

4: Pump monitoring

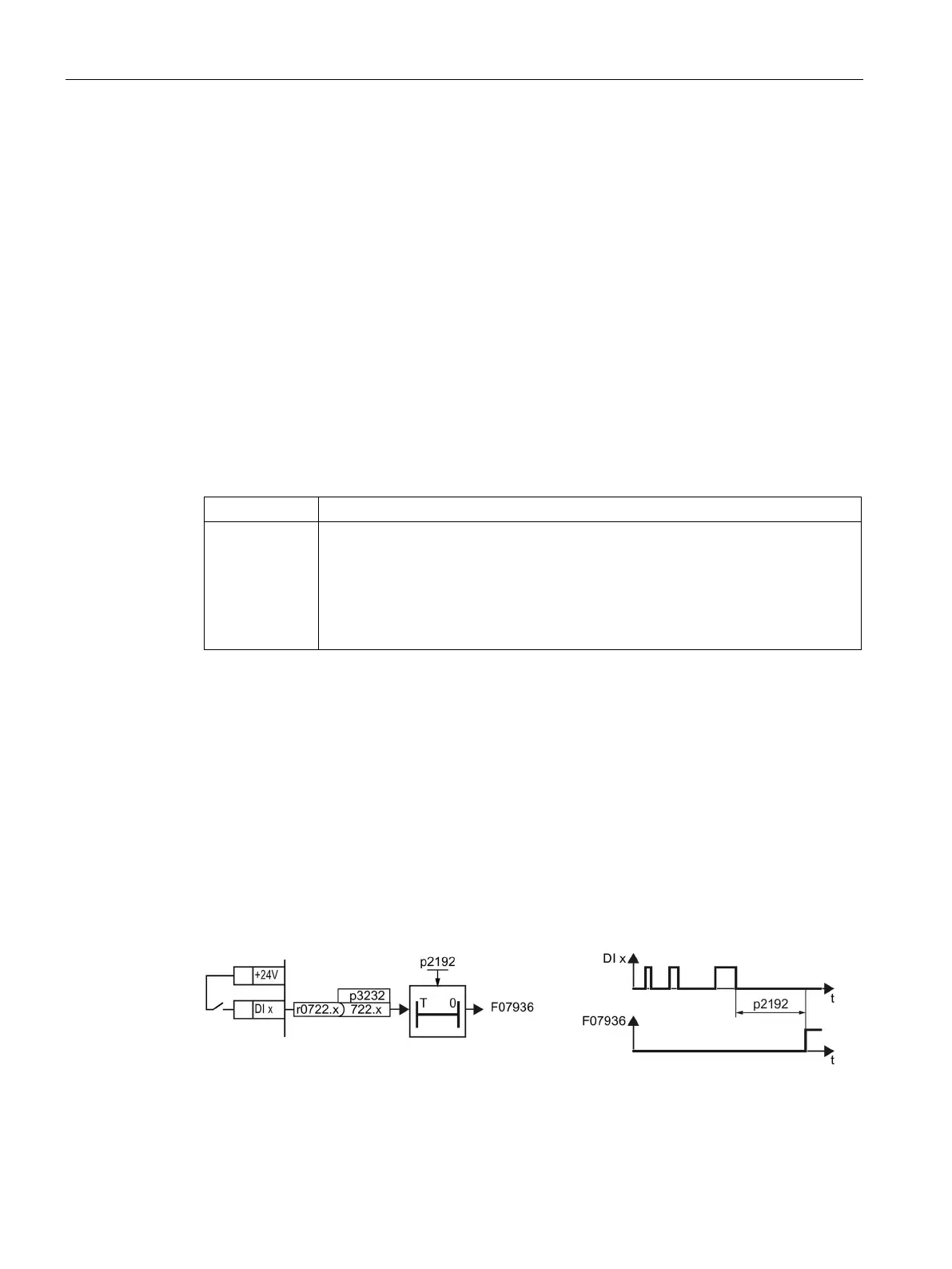

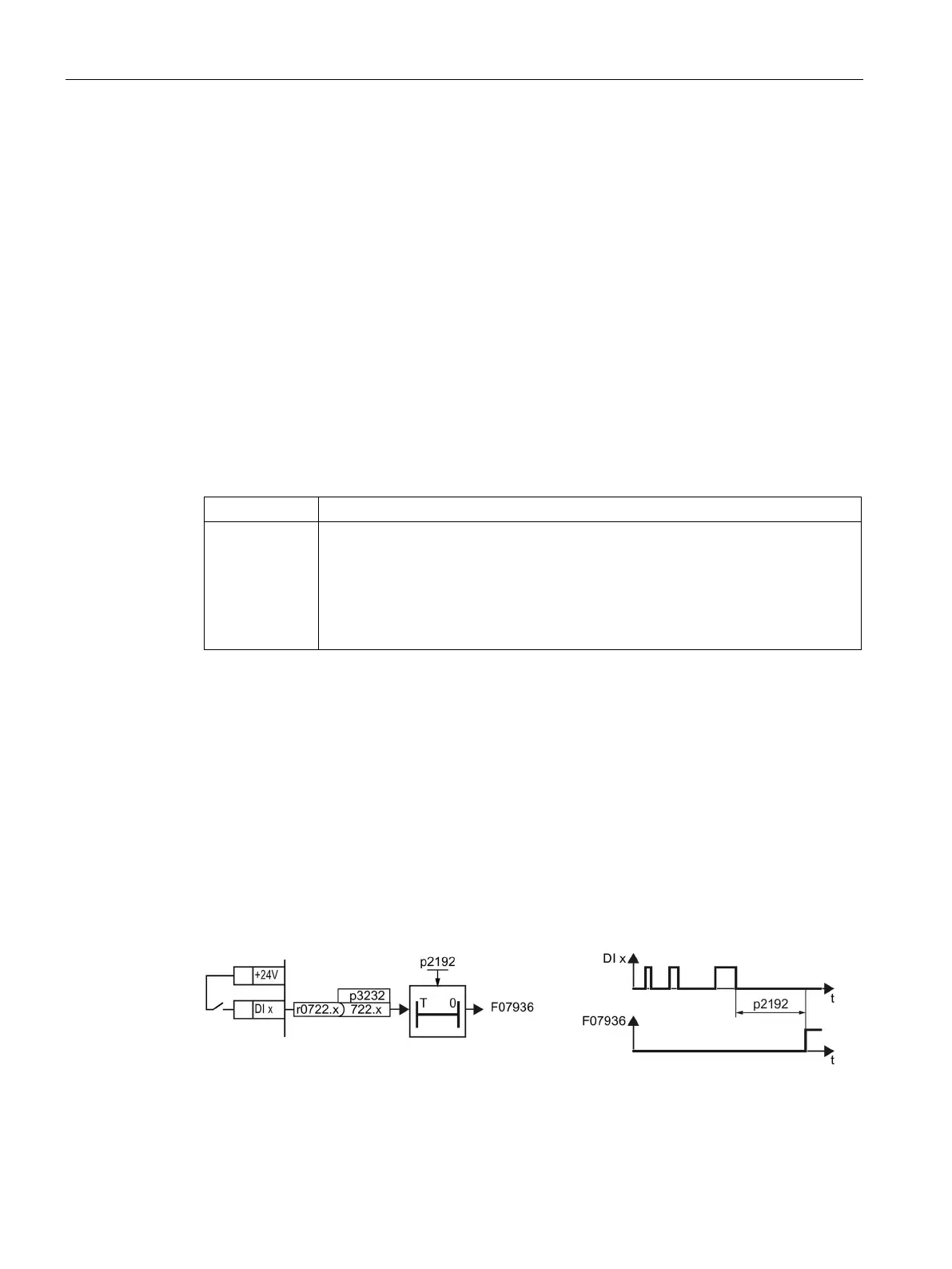

Load failure monitoring

Principle of operation

Using this function, the inverter monitors the speed or velocity of a machine component. The

inverter evaluates whether an encoder signal is present. If the encoder signal fails for a time

that can be adjusted, then the inverter signals a fault.

Examples of how the function can be used:

● Gearbox monitoring for traction drives and hoisting gear

● Drive belt monitoring for fans and conveyor belts

● Blocking protection for pumps and conveyor belts

Image 6-58 Function plan and time response of load-interruption monitoring

Loading...

Loading...