Commissioning

9.2 Commissioning guidelines

S7-1500 Motion Control V13 Update 3

Function Manual, 07/2014, A5E03879256-AC

201

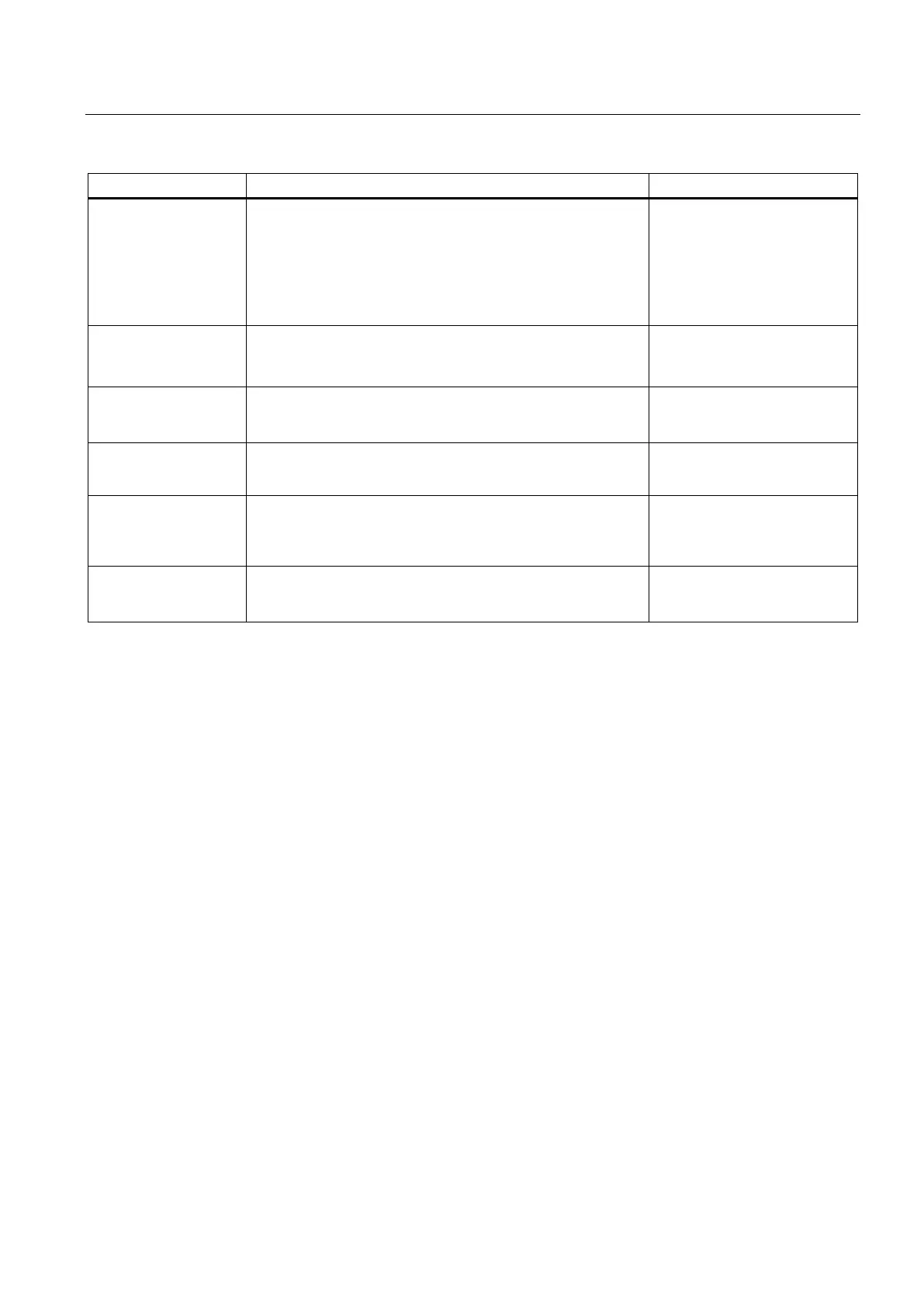

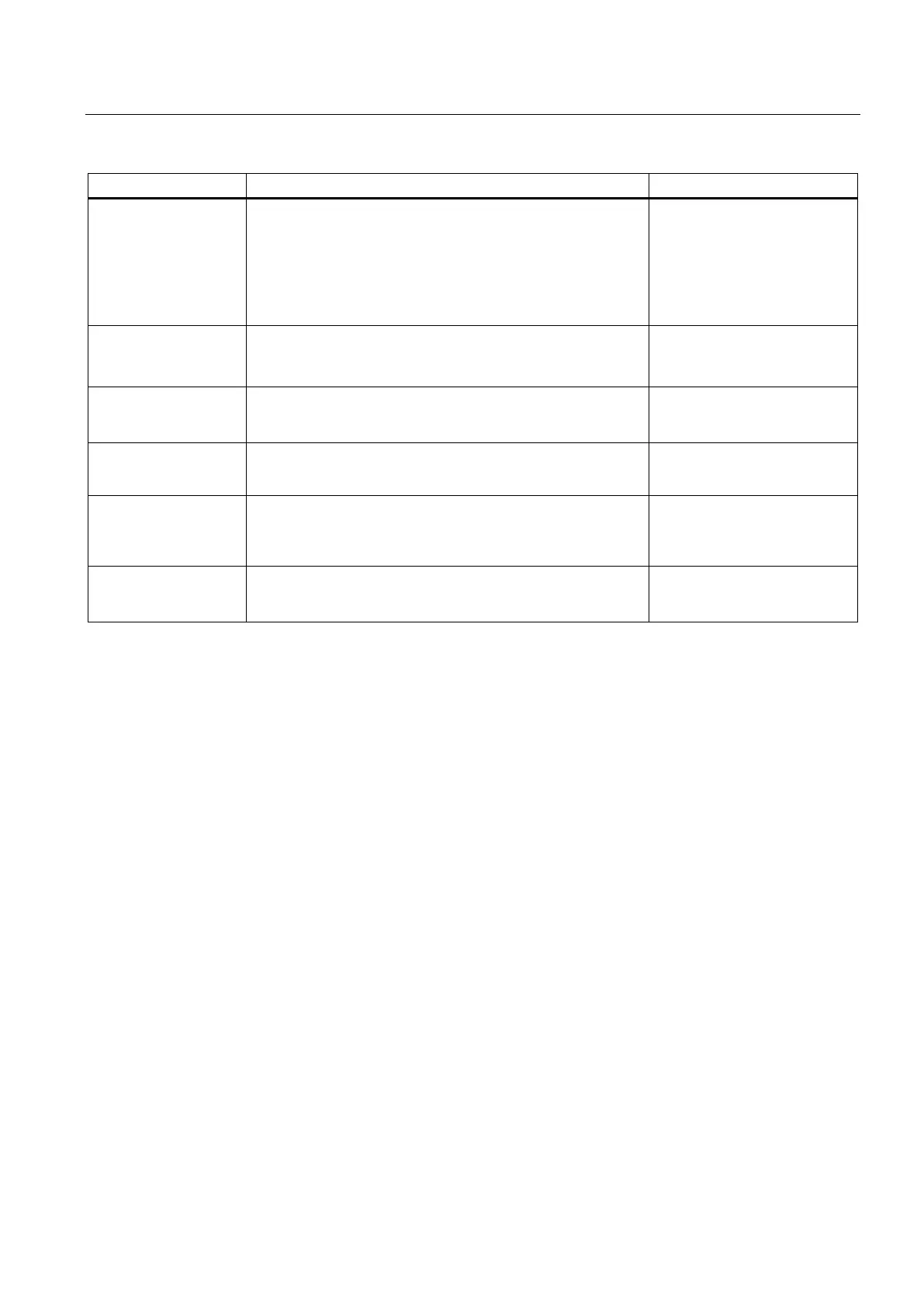

Checking the reference

speed

Traverse the axis in jog mode at low velocity in the positive

direction.

⇒ The displayed current velocity must match the velocity set-

point.

If the displayed current velocity deviates significantly from the

velocity setpoint, adjust the reference speed.

• "Technology object > Hard-

ware interface > Data ex-

change"

• "Technology object > Com-

missioning > Axis control

panel"

Optimize position con-

troller

Use the Optimization (Page 207) commissioning function to

optimize the gain (Kv) of the position control loop.

For this purpose, adapt following error limits as needed.

"Technology object > Commis-

sioning > Optimization"

Transfer the gain Kv to

the project.

Enter the gain Kv that you determined by means of the optimi-

zation function in your configuration data. Load your project

"Technology object > Configu-

ration > Extended parameters >

Enable Motion Control

specific user program

Unlock the enabling technology objects lock in your user pro-

gram (MC_Power.Enable = TRUE).

• PLC programming

• Motion Control instructions

Check the functioning

of the user program

Check the programmed functions of your user program.

• Watch and force tables

• Online and diagnostic func-

tions

End of commissioning

for a positioning axis

To commission additional technology objects, perform the

corresponding steps again.

See above.

Loading...

Loading...