Velocities, Setpoint/Actual Value Systems, Closed-Loop Control (G2)

7.2 Metric/inch measuring system

Turning, Milling, Nibbling

120 Function Manual, 11/2012, 6FC5397-1CP10-5BA0

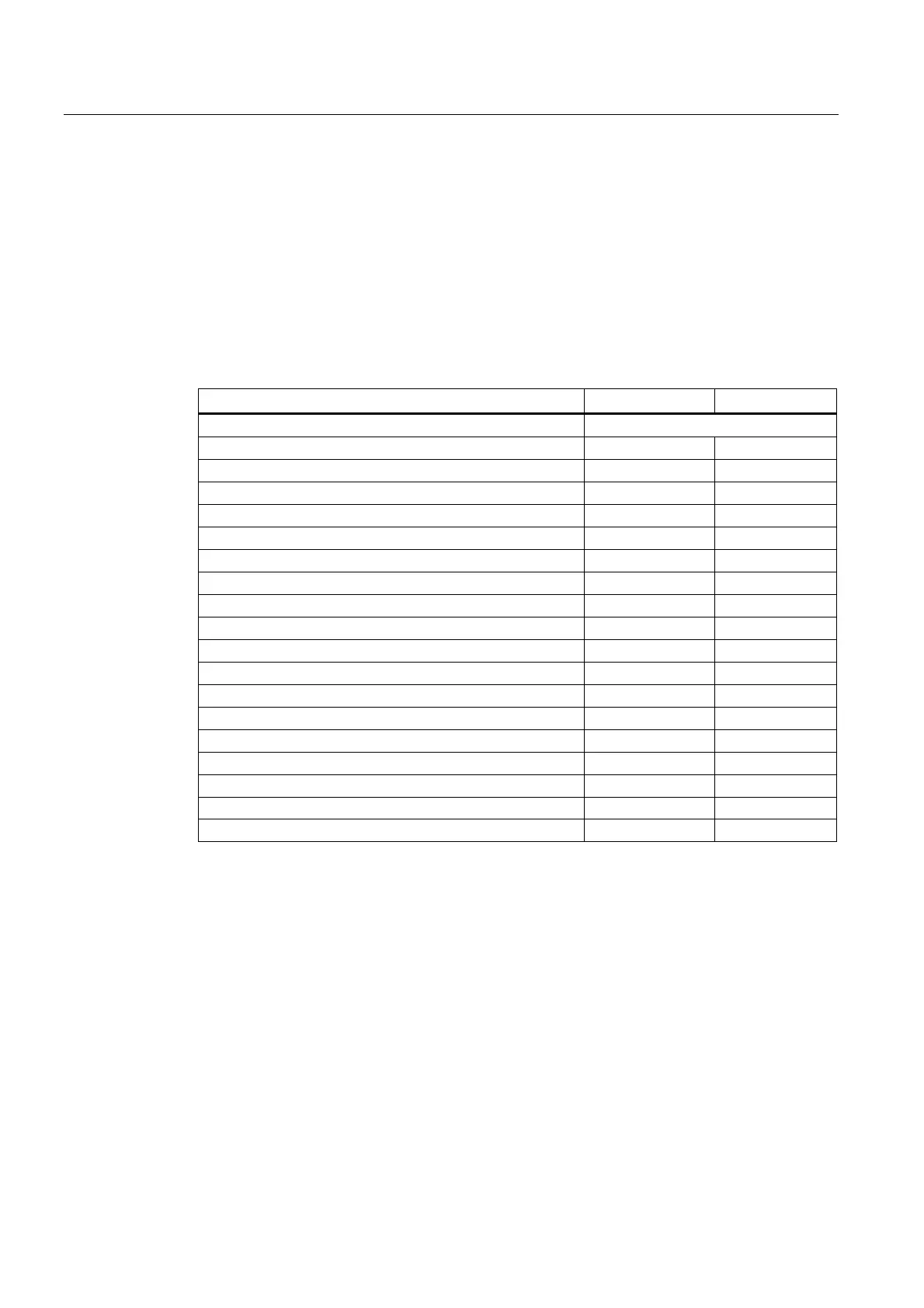

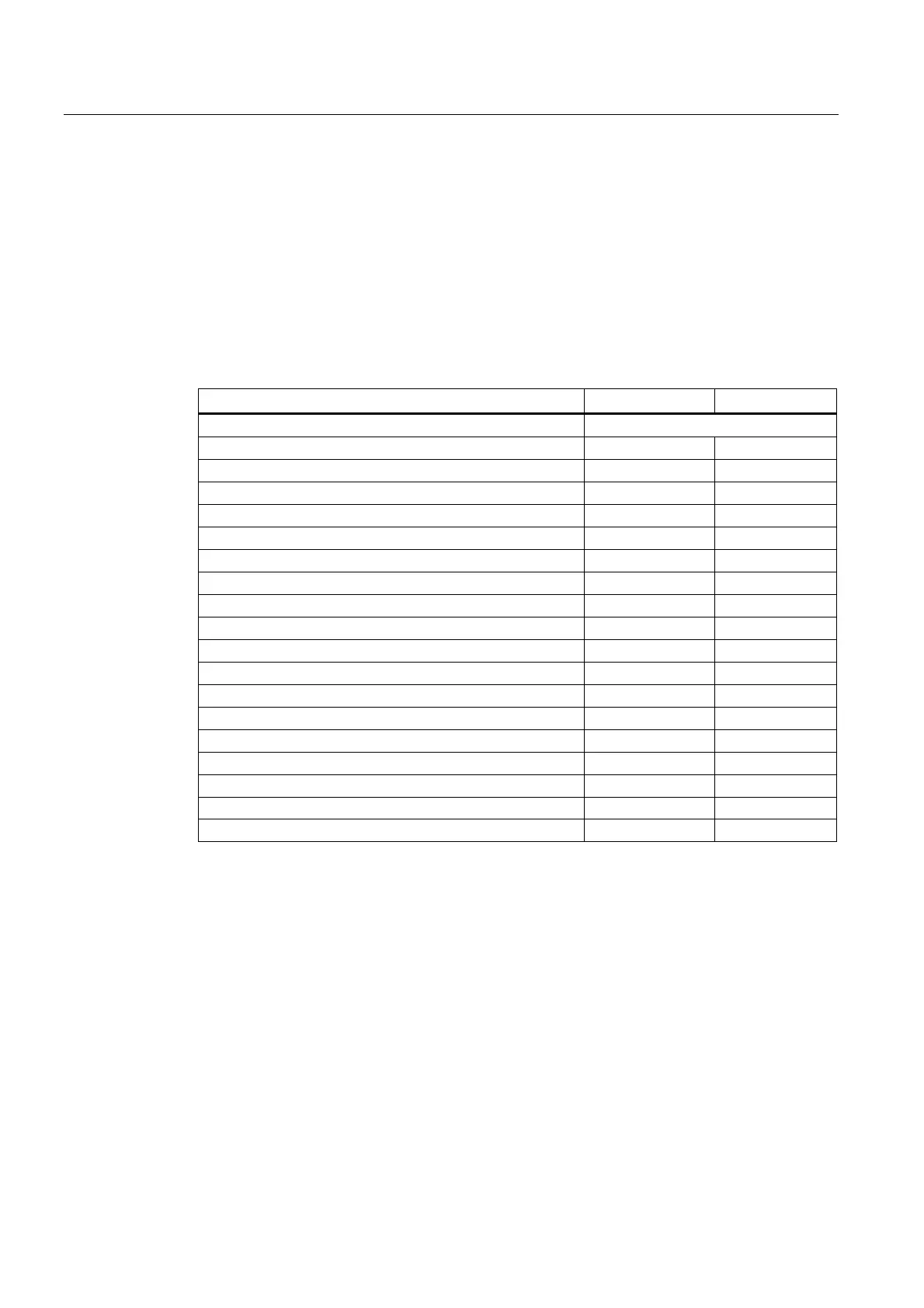

Comparison: G70/G71-G700/G710

Where:

P: Data is read/written in the programmed measuring system.

G: Data is read/written in the basic system (MD10240)

R/W: Read/Write

Table 7- 2 Comparison

Area G70/G71 G700/G710

R/W part program

Display, decimal places (WCS) P/P P/P

Display, decimal places (MCS) G/G G/G

Feed rates G/G P/P

Positional data X, Y, Z P/P P/P

Interpolation parameters I, J, K P/P P/P

Circle radius (CR) P/P P/P

Polar radius (RP) P/P P/P

Pitch P/P P/P

Programmable offset, rotation,... P/P P/P

Programmable offset G54, G55, etc. G/G P/P

Working area limits (G25/G26) G/G P/P

Tool offsets G/G P/P

Length-related machine data G/G P/P

Length-related setting data G/G P/P

Length-related system variables G/G P/P

R parameters G/G G/G

Siemens cycles P/P P/P

Jog/handwheel increment factor G/G G/G

7.2.2 Manual switchover of the basic system

General

The dimension system for the whole machine is changed using an HMI softkey "Switch to

mm > inch" or "Switch to inch > mm" located in the "POSITION" → "Settings" area. The

softkey can only be accessed in JOG or MDA mode. The switchover is only accepted if:

● The channel is in reset status

● The axes are not being traversed.

Actions such as NC start or mode change are disabled for the duration of the changeover.

Loading...

Loading...