Spindle (S1)

20.8 Analog spindle

Turning, Milling, Nibbling

Function Manual, 11/2012, 6FC5397-1CP10-5BA0

365

20.8 Analog spindle

Function

With the "Analog spindle" function, the MCPA option module is used as the setpoint output,

and a free DRIVE-CLiQ encoder interface is used as the actual-value input.

For more detailed information see the "adi4.ini" file, which is part of the toolbox and can be

found in the "...\Toolbox 802D_sl\V01040000\Special\ADI4" directory.

For the analog spindle without encoder, MD30240 ENC_TYPE[n] must be set to zero.

20.9 Data lists

20.9.1 Machine data

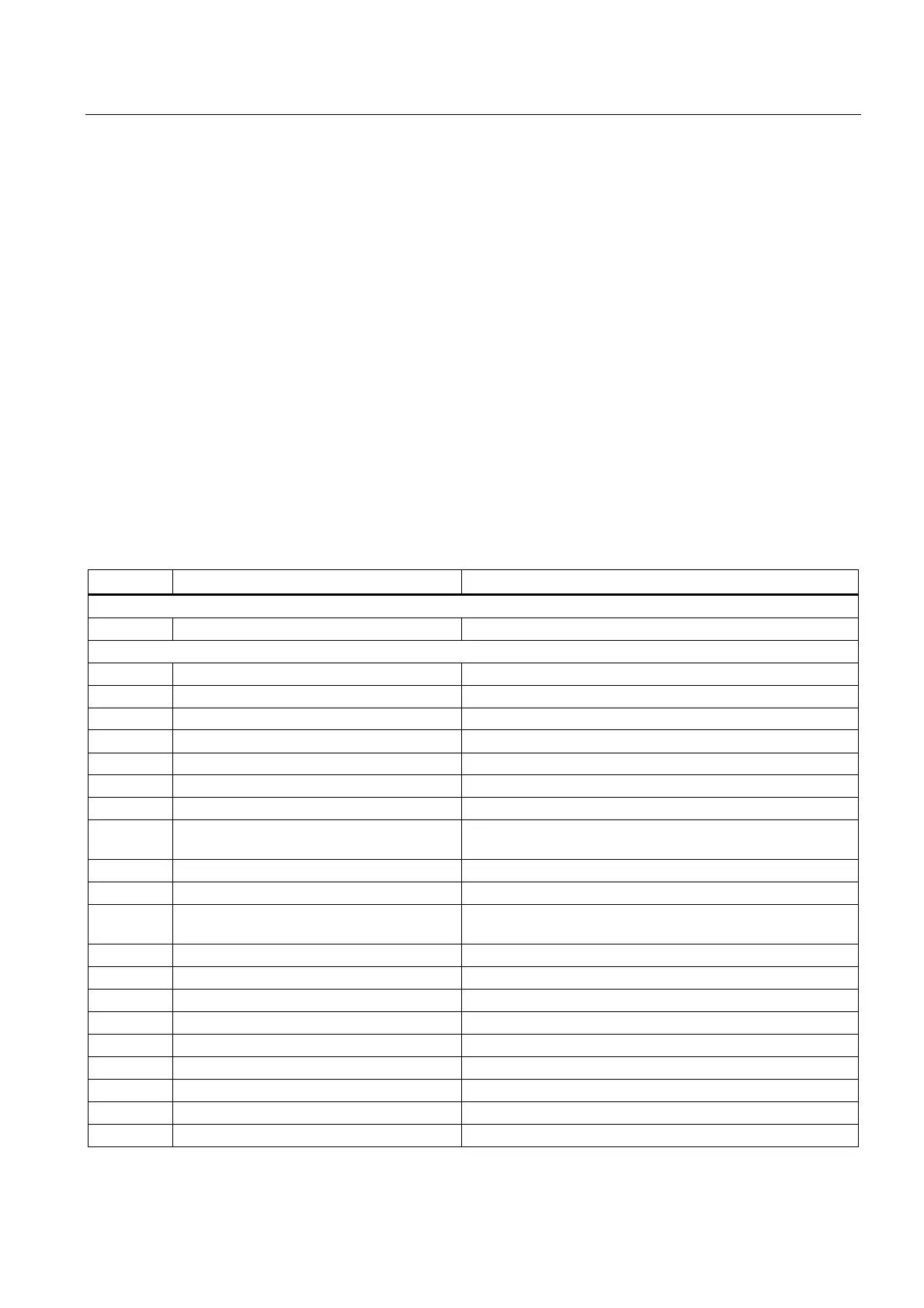

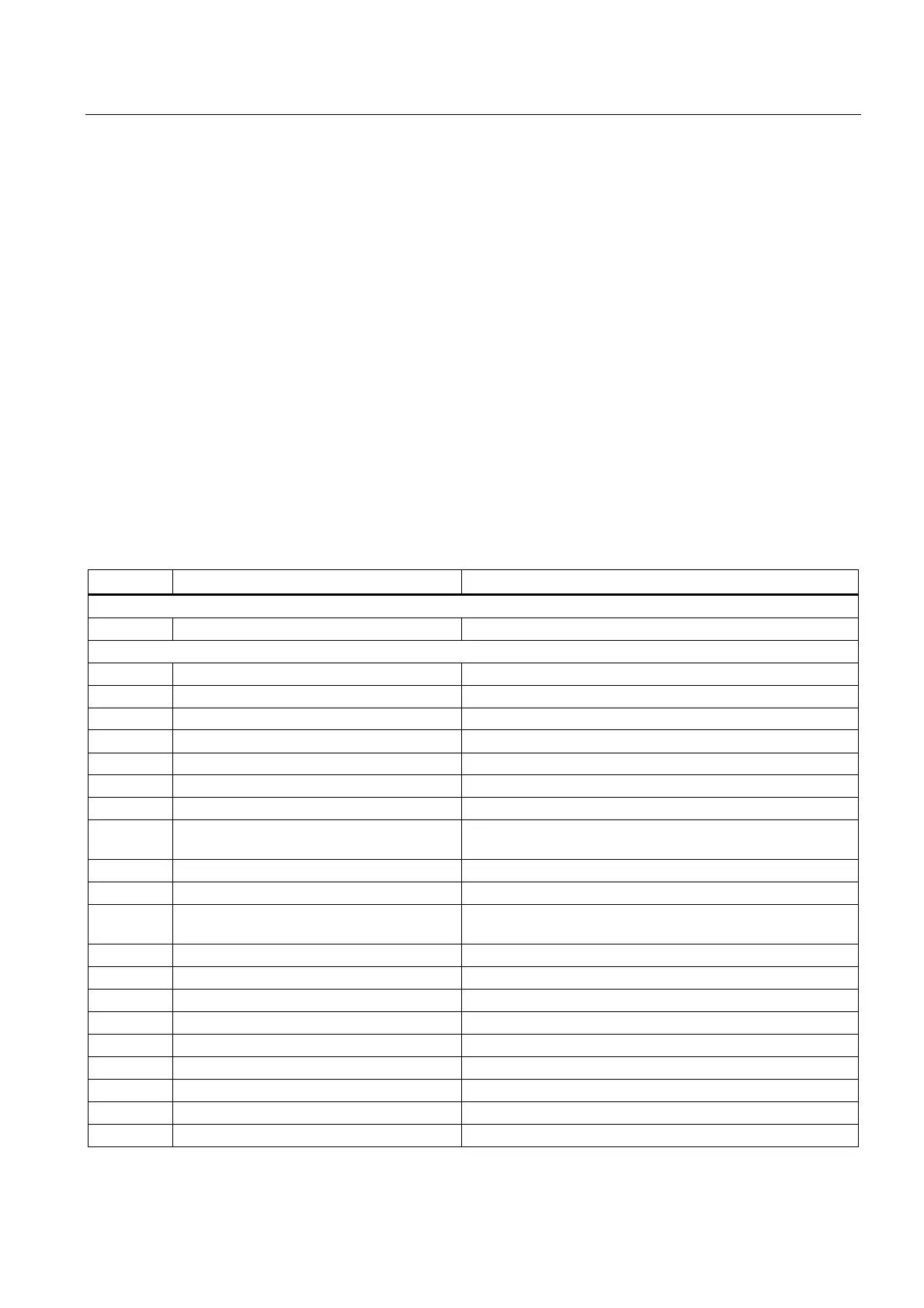

Number Identifier Name

Channel-specific

20090 SPIND_DEF_MASTER_SPIND Master spindle

Axis-specific

30134 IS_UNIPOLAR_OUTPUT[0] Setpoint output is unipolar

30300 IS_ROT_AX Rotary axis

30310 ROT_IS_MODULO Modulo conversion

30320 DISPLAY_IS_MODULO Position display

31050 * DRIVE_AX_RATIO_DENOM[n] Denominator load gearbox

31060 * DRIVE_AX_RATIO_NUMERA[n] Numerator load gearbox

32200 * POSCTRL_GAIN [n] Servo gain factor Kv

32810 * EQUIV_SPEEDCTRL_TIME [n] Equivalent time constant speed control circuit for feedforward

control

34040 REFP_VELO_SEARCH_MARKER Reference point creep speed

34060 REFP_MAX_MARKER_DIST Monitoring of zero mark distance

34080 REFP_MOVE_DIST Reference point distance/destination point for distancecoded

system

34090 REFP_MOVE_DIST_CORR Reference point offset/absolute offset, distancecoded

34100 REFP_SET_POS Reference point value

34200 ENC_REFP_MODE Referencing mode

35000 SPIND_ASSIGN_TO_MACHAX Assignment of spindle to machine axis

35010 GEAR_STEP_CHANGE_ENABLE Gear stage change possible

35040 SPIND_ACTIVE_AFTER_RESET Spindle active after reset

35100 SPIND_VELO_LIMIT Maximum spindle speed

35110 * GEAR_STEP_MAX_VELO[n] Maximum speed for gear change

35120 * GEAR_STEP_MIN_VELO[n] Minimum speed for gear change

Loading...

Loading...