Compensation (K3)

11.4 Following error compensation (feedforward control)

Turning, Milling, Nibbling

Function Manual, 11/2012, 6FC5397-1CP10-5BA0

227

Optimization of control loop

The feedforward control is set on an axis/spindle-specific basis. First of all, the current

control loop, speed control loop and position control loop must be set to an optimum for the

axis/spindle.

Reference:

/BE/ Operating Instructions

Parameter assignments

The feedforward control parameters must then be assigned to the relevant axis/spindle and

then entered in the machine data (see next section).

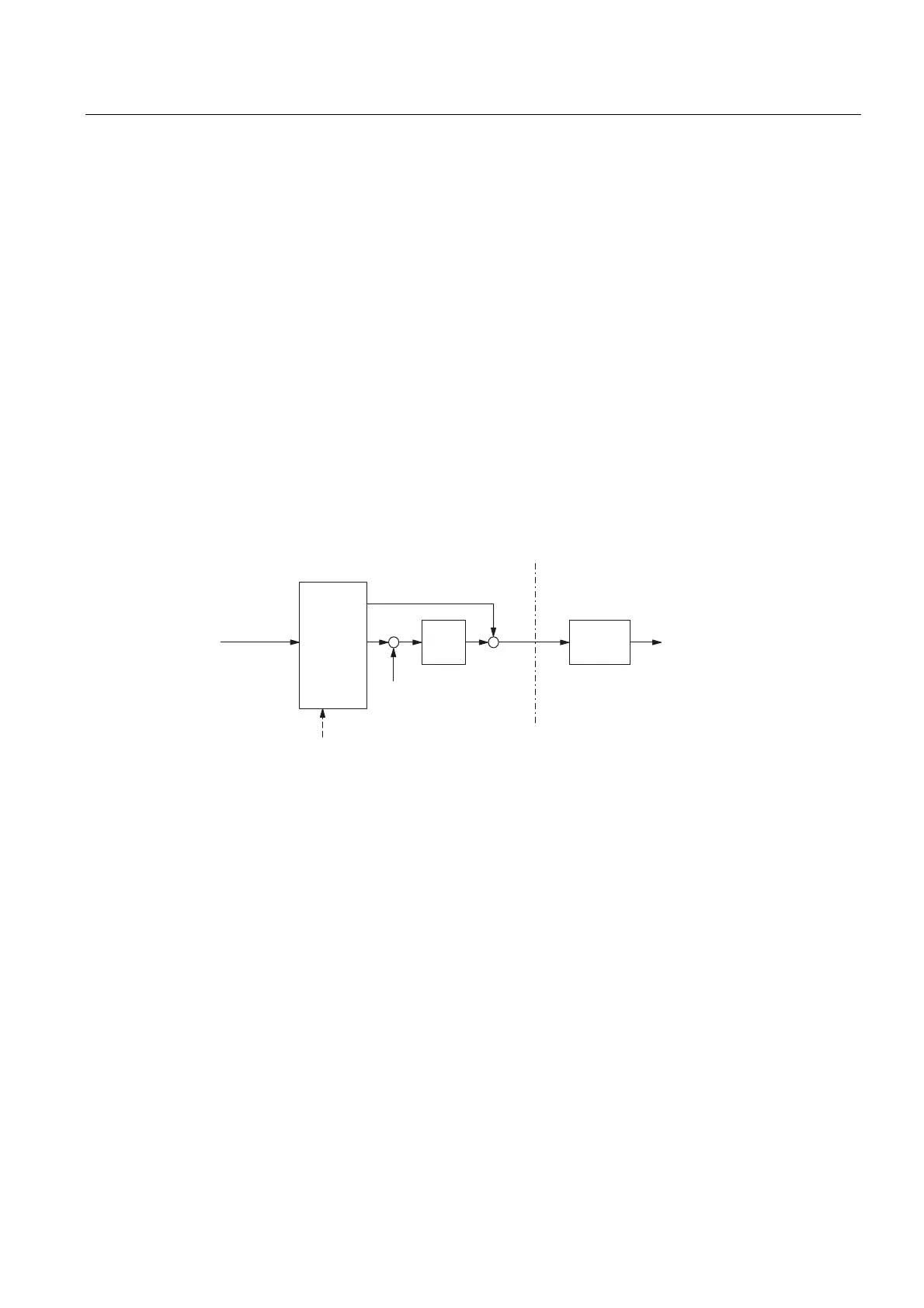

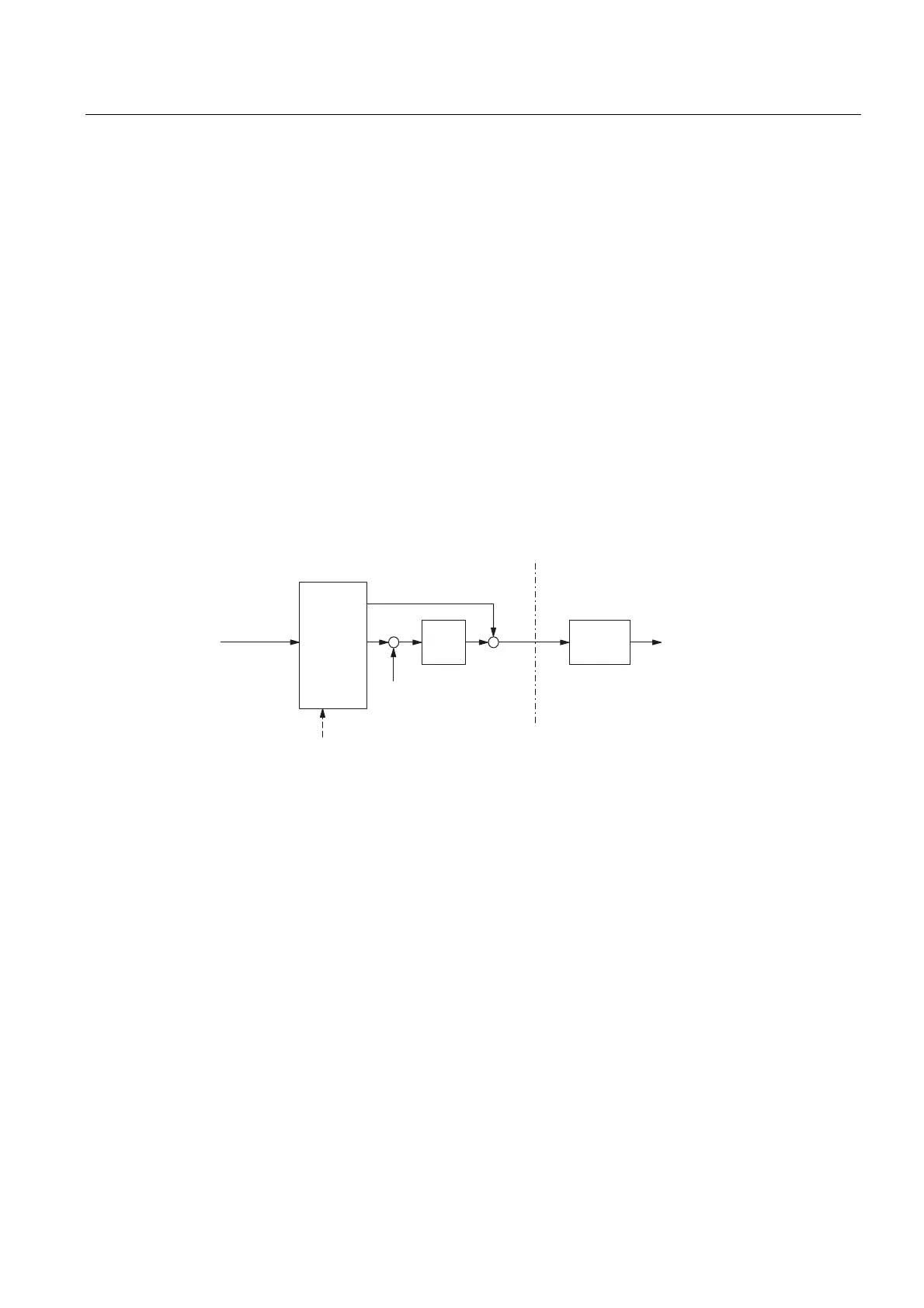

11.4.2 Speed feedforward control

In the case of speed feedforward control, a velocity setpoint is also applied directly to the

input of the speed controller (see figure below).

0'(48,9B63(('&75/B7,0(

'ULYH1&.

3RVLWLRQ

DFWXDOYDOXH

6SHHG

FRQWUROOHU

3RVLWLRQ

FRQWURO

OHU

UHIHUHQFH

YDOXH

6HWSRLQW

)HHGIRUZDUG

FRQWURO

Figure 11-8 Speed feedforward control

Parameters

In order to achieve a correctly set speed feedforward control, the equivalent time constant of

the speed control loop must be determined exactly and entered as machine data

MD32810 EQUIV_SPEEDCTRL_TIME (equivalent time constant of the closed speed control

loop) during commissioning.

Loading...

Loading...