Velocities, Setpoint/Actual Value Systems, Closed-Loop Control (G2)

7.4 Closed-loop control

Turning, Milling, Nibbling

134 Function Manual, 11/2012, 6FC5397-1CP10-5BA0

0'326&75/B*$,1

0')):B02'(

0'):B$&7,9$7,21B02'(

0'9(/2B)):B:(,*+7

0'48,9B63(('&75/B7,0(

0'(1&B)(('%$&.B32/

0'(1&B&203B(1$%/(

0'%$&./$6+

0'$;B027,21B',5

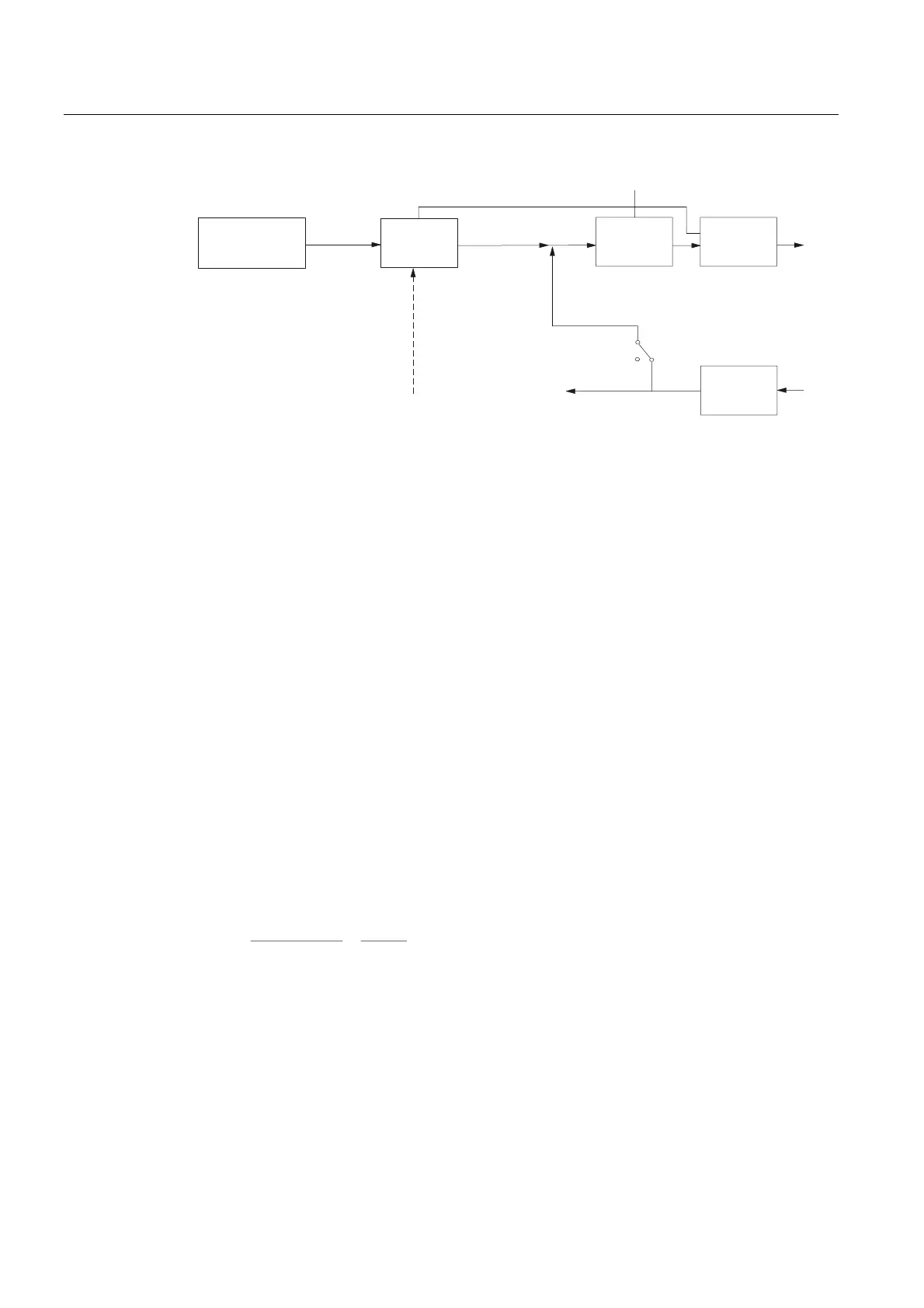

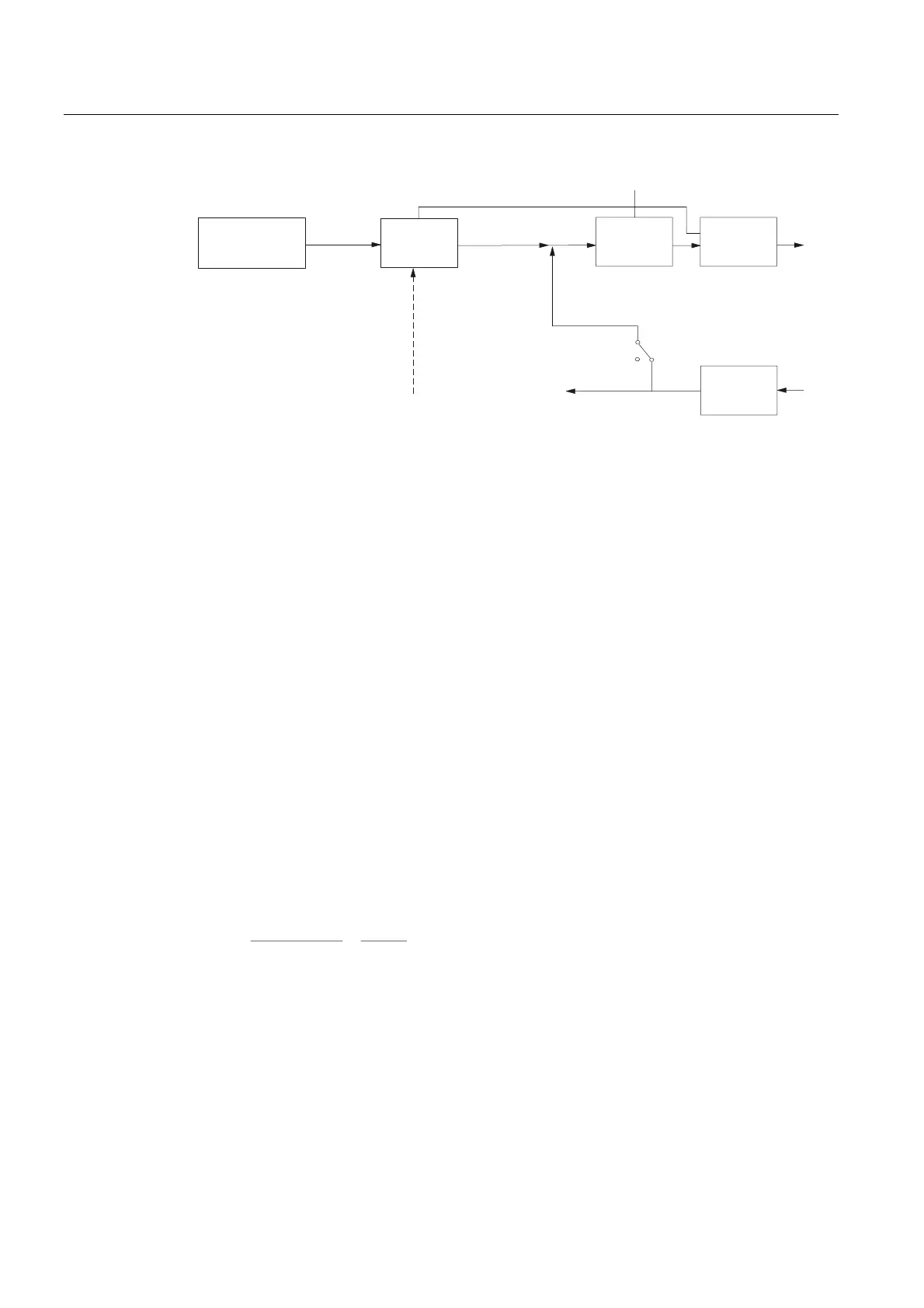

,63RVLWLRQPHDVXULQJV\VWHP

,QWHUSRODWRU

-HUNOLPLWDWLRQ

6SHHG

VHWSRLQW

SURFHVVLQJ

&ORVHGORRS

FRQWURO

)HHGIRUZDUG

FRQWURO

$FWXDOYDOXH

SURFHVVLQJ

Figure 7-11 Principle of position control for an axis/spindle

For a description of jerk limiting, see the section titled "Acceleration"

For a description of precontrol, backlash compensation, and leadscrew error compensation,

refer to the section titled "Compensation (K3)".

Servo gain factor

To ensure that only low contour deviations occur in continuous-path mode, a high servo gain

factor MD32200 POSCTRL_GAIN[n] (position controller servo gain) is required.

The index[n] of the machine data has the following code:

[closed-loop control parameter set no.]: 0 - 5

However, if the servo gain factor is too high, this will result in instability, overshoots, and

possibly impermissibly high loads on the machine.

The maximum permissible servo gain factor depends on the following:

● Design and dynamic response of the drive

(rise time, acceleration and braking capacity)

● Quality of the machine (elasticity, vibration damping)

● Position-control cycle

)ROORZLQJHUURU

9HORFLW\

>PP@

>PPLQ@

.Y

8QLWRIVHUYRJDLQIDFWRUDFFWR9',VWDQGDUG

Parameter sets of the position controller

Position control can operate with 6 different parameter sets. This information is used for

● Fast adaptation of position control to altered machine characteristics during operation,

e.g. a spindle gear change.

● Matching the dynamic response of an axis to another axis, e.g. during tapping.

Loading...

Loading...