Punching and Nibbling (N4)

15.8 Data lists

Turning, Milling, Nibbling

302 Function Manual, 11/2012, 6FC5397-1CP10-5BA0

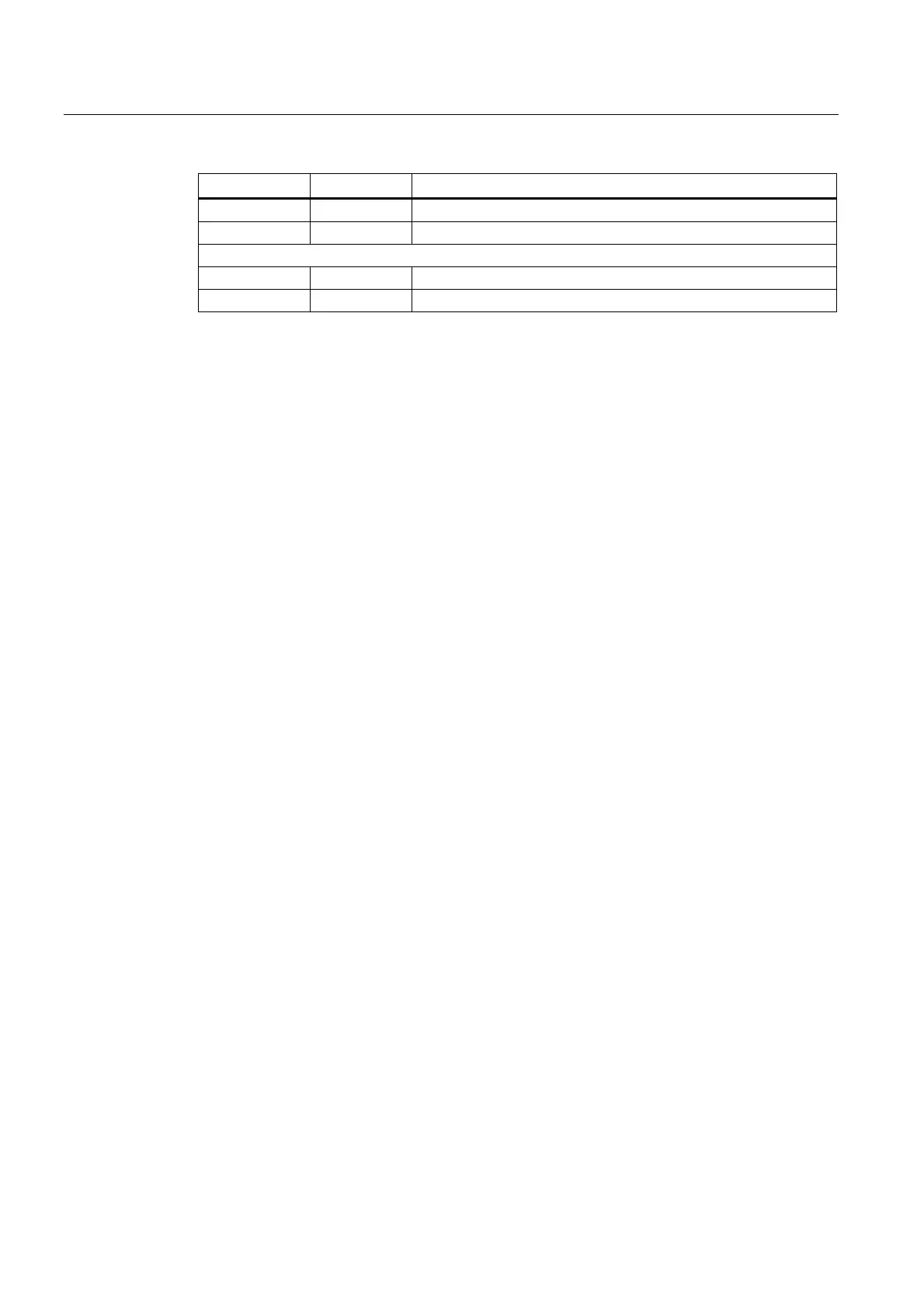

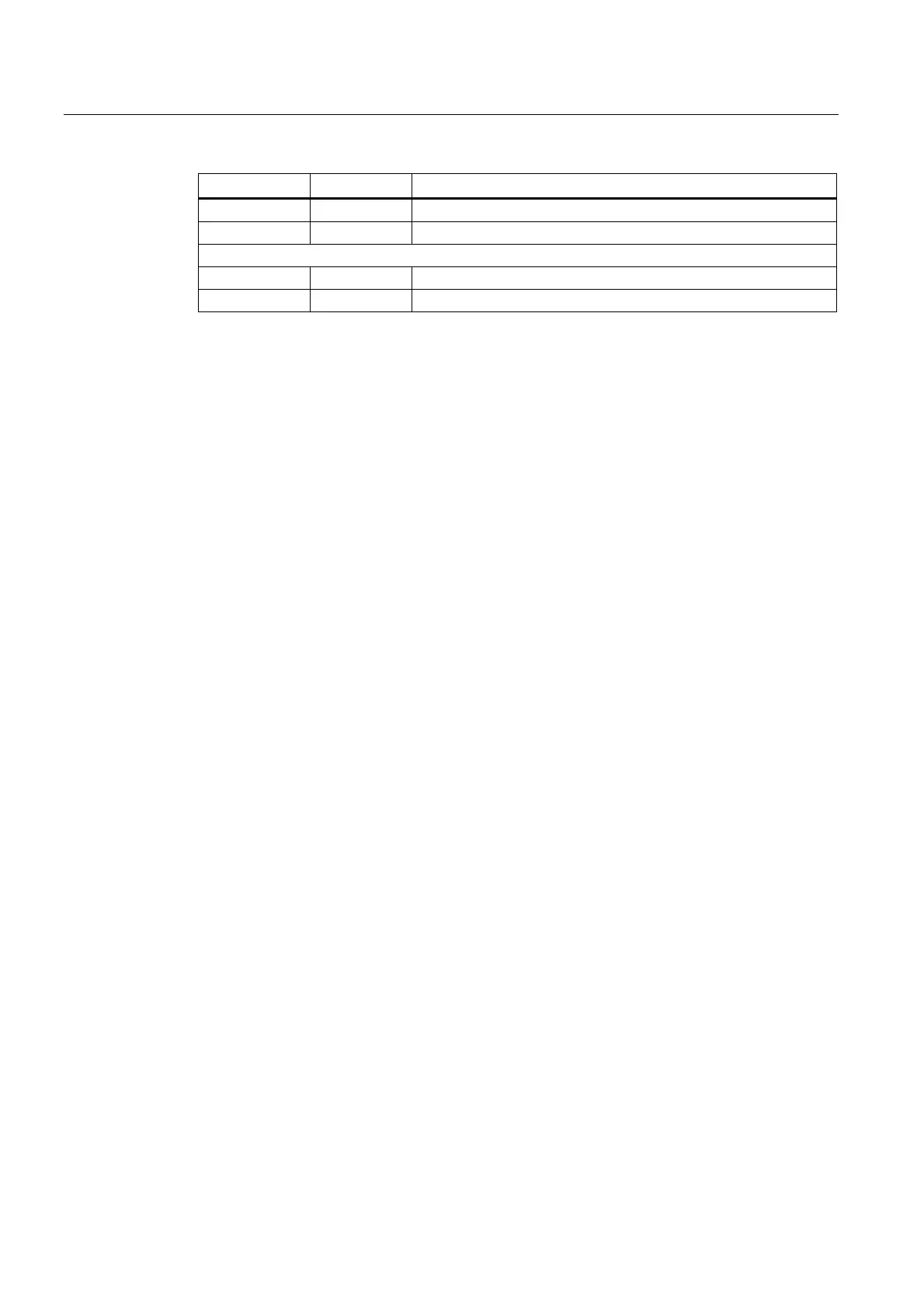

Number Bit Name

V3200 0003 .4 Delayed stroke

V3200 0003 .5 Manual stroke initiation

Signals from channel

V3300 0006 .0 Stroke initiation active

V3300 0006 .1 Acknowledgement of manual stroke initiation

Loading...

Loading...