Commissioning Manual

6FC5397-4EP10-0BA8, 07/2018

141

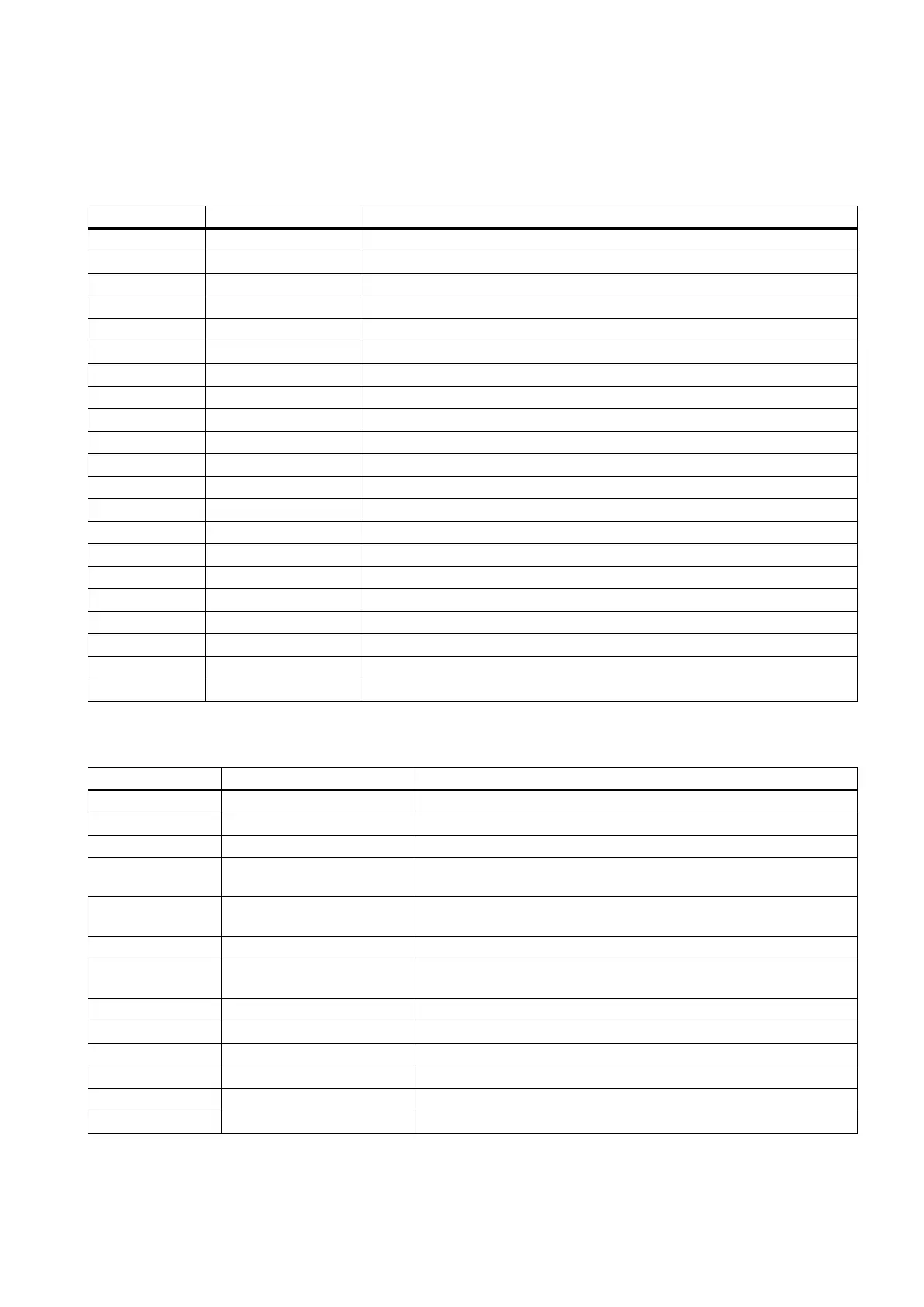

Structure of symbol tables

All the addresses in the PLC subroutine library are programmed with symbols. All the signals of interfaces are named by

symbols and arranged in different symbol tables.

The name of a symbol follows some conventions. For details, see Section "Conventions for the symbols used in the

subroutines (Page 143)".

Module I/O are defined by the manufacturer

Distributed I/O are defined by the manufacturer

Reserved for the manufacturer

PLC selects part programs

Auxiliary functions from the NCK

Signals from/to the channel

21 IS_AX1 Signals to/from axis 1

Global memory used in the sample applications and subroutines

Reserved for the sample applications and subroutines

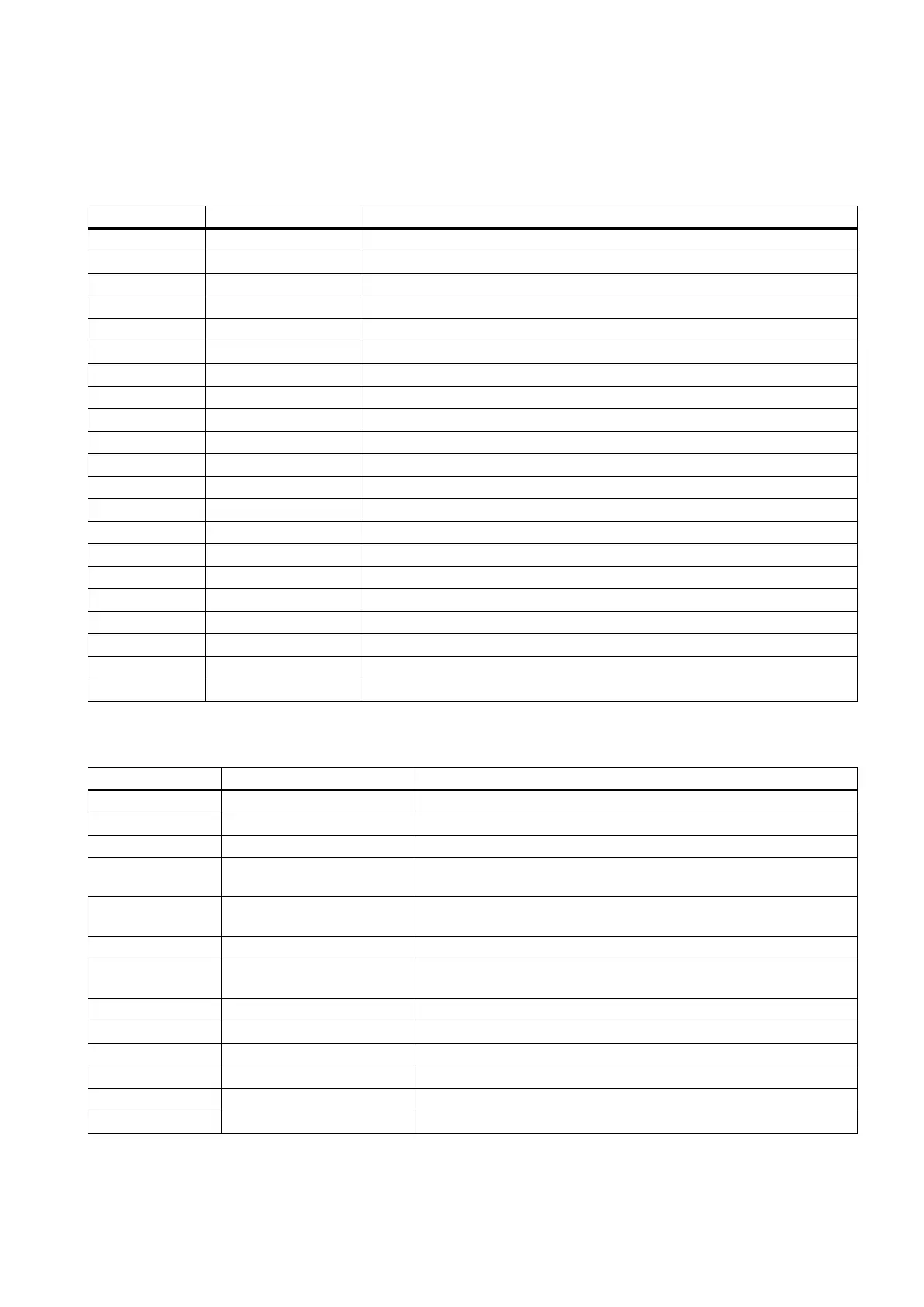

PLC sample subroutines offer PLC functions for the machine tool.

Working lamp control, called in the subroutine "AUX_MCP"

22 AUX_SAFE_DOOR Safety door control, called in the subroutine "AUX_MCP" for a milling

23 AUX_CHIP Chip conveyor control, called in the subroutine "AUX_MCP" for a

Three-color lamp control, called in the subroutine "AUX_MCP"

31 PLC_ini_USR_INI Reserved for initialization functions of the manufacturer (this subrou-

tine is automatically called by subroutine 32)

PLC initialization, executed at the first PLC cycle (SM0.1)

Signals from the MCP and HMI are sent to NCK interfaces

38 MCP_Tool_Nr Display tool numbers via the 7-segment LED of the MCP

Handwheel selection via the HMI

40 AXIS_CTL Control of feed axis enable and spindle enable

Loading...

Loading...