Commissioning Manual

6FC5397-4EP10-0BA8, 07/2018

151

Subroutine 39 - HANDWHL (selecting a handwheel according to HMI interface

signals)

Purpose

Subroutine 39 is used to select one of the two handwheels to control an axis (X, Y or Z) in the machine coordinate system or

the workpiece coordinate system according to the HMI signals. With the HANDWHEEL key and axis selection key on the

MCP, you can assign the handwheel 1 in the workpiece coordinate system to any axis.

Note

You cannot use subroutine 39 together with subroutine 41

- MINI_HHU.

Local variable definition

None

None

Relevant PLC machine data

14512 [16].7

Handwheel assignment with the HMI

0 Handwheel assignment with the MCP

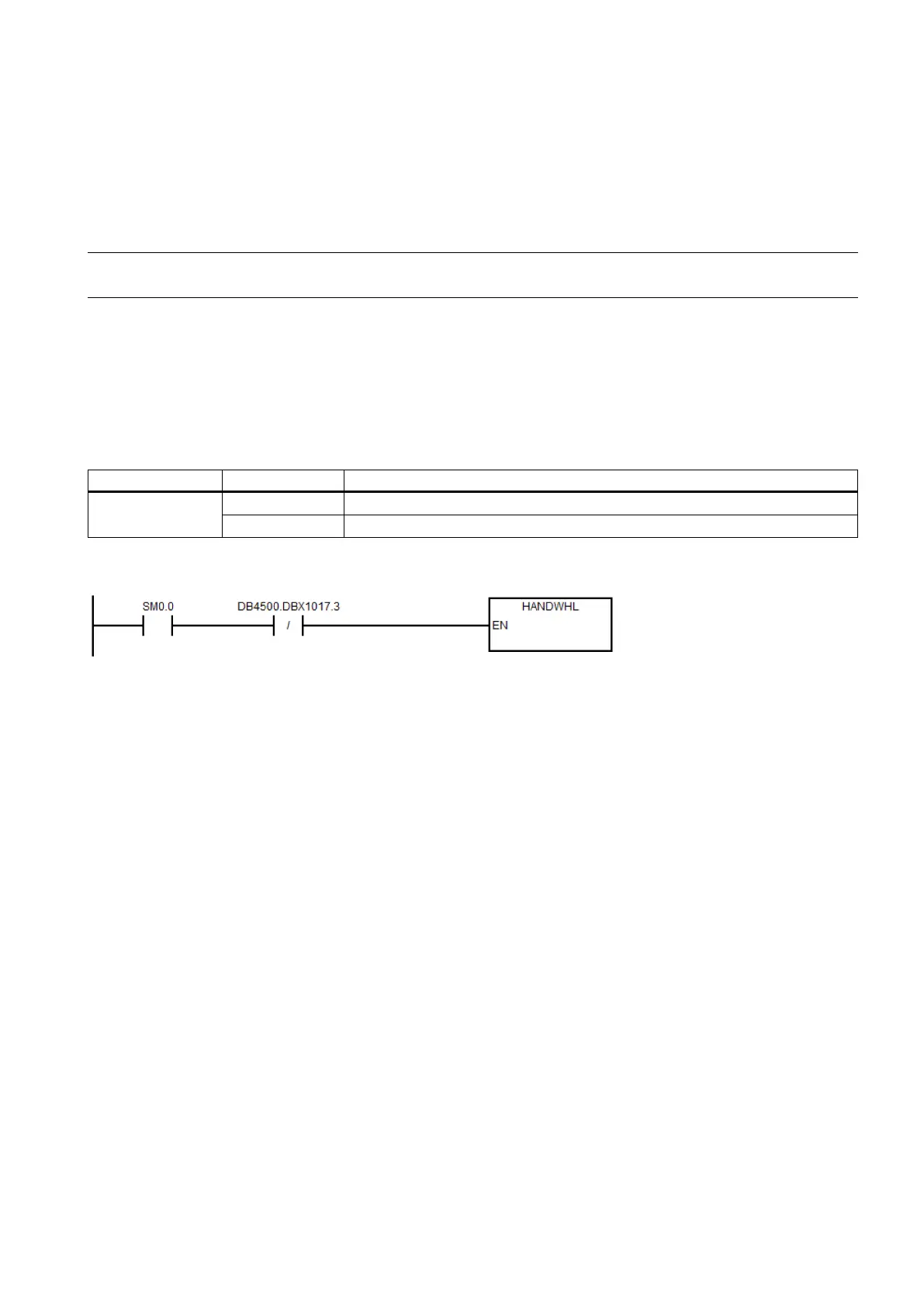

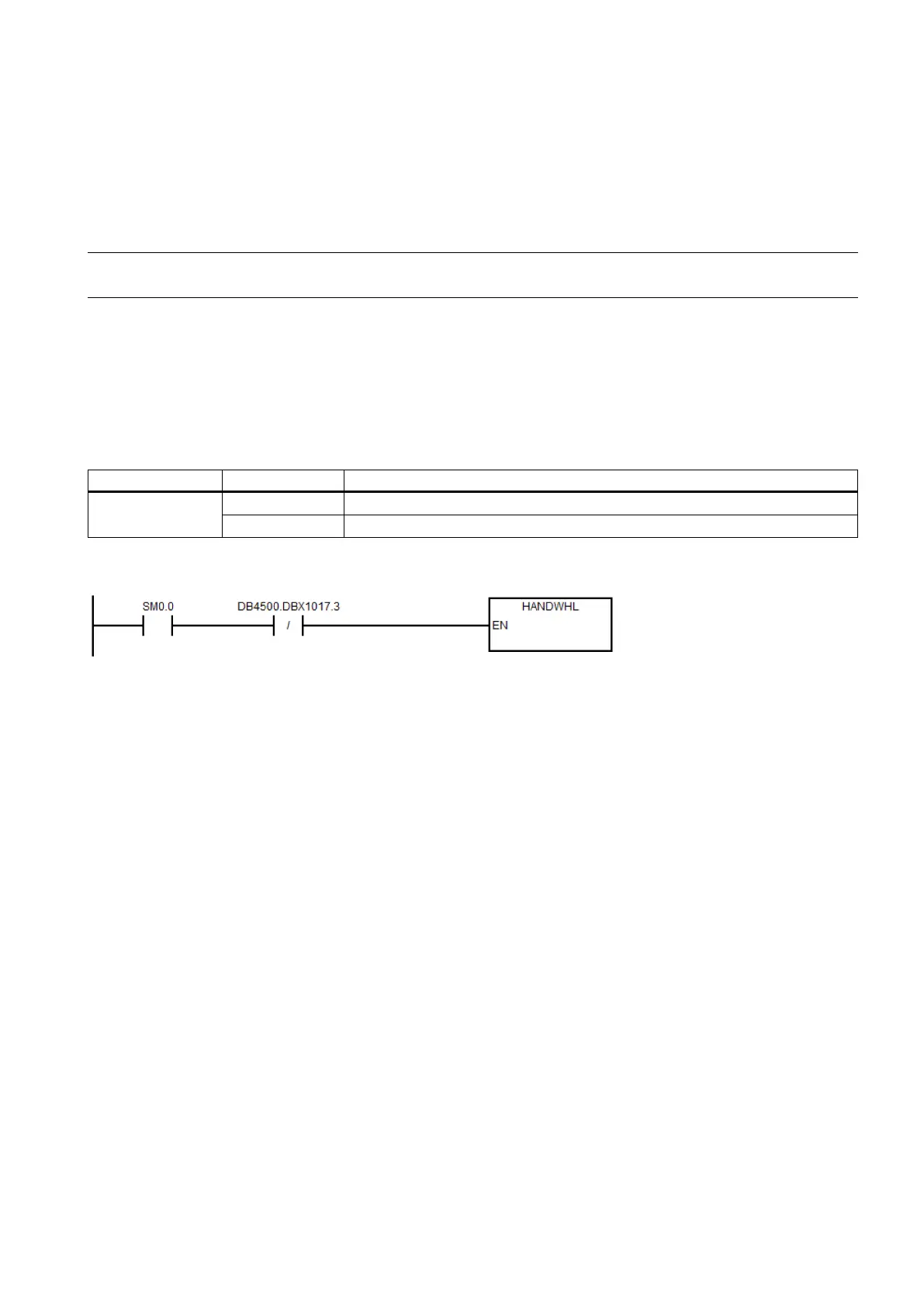

Example for calling subroutine 39

Subroutine 40 - AXIS_CTL (controlling the spindle and axes)

Purpose

Subroutine 40 is used to control the drive pulse enable (DB380x.DBX4001.7) and controller enable (DB380x.DBX2.1),

monitoring the hardware limits and the reference cam signals, and controlling the enable signal for the spindle according to a

spindle command (for example, SPINDLE CW, SPINDLE CCW, M03, M04, SPOS, etc.). The motor brake is automatically

controlled by the SINAMICS V70 drives.

This subroutine provides two ways to realize the hardware limit control:

● PLC solution (MD14512 [18] bit 6 = 0)

Each feed axis has one (MD14512 [18] bit 7 = 1) or two (MD14512 [18] bit 7 = 0) hardware limit switches. This

subroutine activates the NCK hardware limit function via the NCK interface DB380x.DBX1000.0 or DB380x.DBX1000.1

according to the configurations of the hardware limit switches, and thus makes the NCK produce a feed stop signal to an

over-distance axis.

Furthermore, you can also connect the output

of this subroutine with the input

of subroutine 33 to

activate the Emergency Stop automatically once the hardware limit of any axis has been reached.

Loading...

Loading...