Commissioning Manual

140 6FC5397-4EP10-0BA8, 07/2018

PLC subroutine library

6.6.1

In order to simplify the PLC design, we provide refined PLC functions which have generality, such as initialization, machine

panel signal processing, emergency stop processing, axis enable control, hard limit, and reference point etc. By adding the

desired subroutine module to the main procedure, plus other supplementary procedures, you can complete the PLC

procedure design easily.

The PLC subroutine library consists of the following files:

● PLC project file: SAMPLE_TURN.PTP (application program as examples for a turning machine)

● PLC project file: SAMPLE_MILL.PTP (application program as examples for a milling machine)

Note

Through these examples, you can clearly realize how to create

or invoke PLC subroutines. You can reorganize PLC

subroutines or modify networks to realize most machine functions, test and debug subroutines of the library.

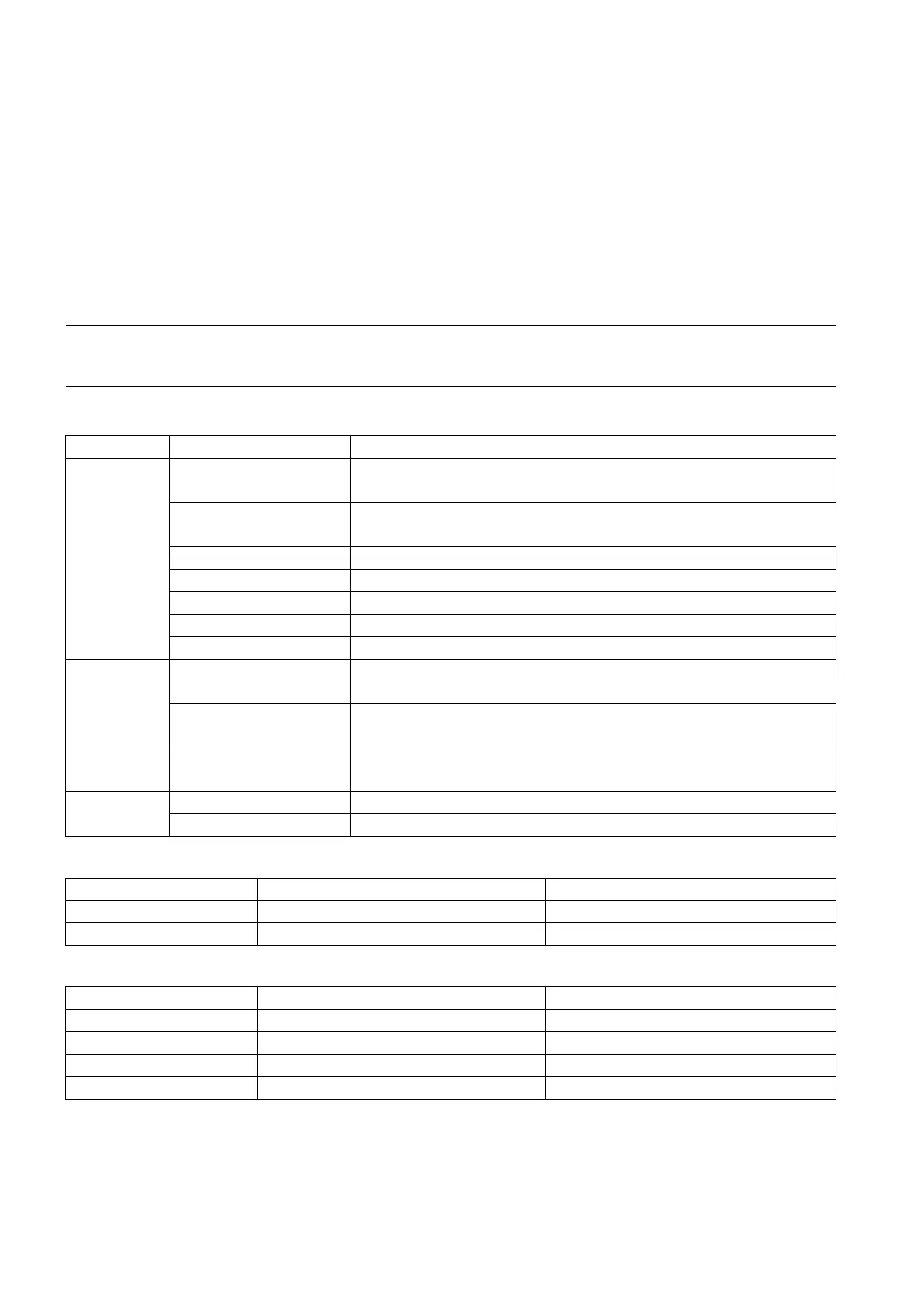

PLC system

resource

Input I0.0 to I2.7 (24 inputs on X100, X101, and X102)

I6.0 to I8.7 (48 distributed inputs on X301 and X302)

Output Q0.0 to Q1.7 (16 outputs on X200 and X201)

Q4.0 to Q5.7 (32 distributed outputs on X301 and X302)

M0.0 to M255.7 (256 bytes)

DB1400.DBX0.0 to DB14000.DBX127.7 (128 bytes)

DB1600.DBX0.0 to DB16000.DBX15.7 (128 user alarms)

T0 to T15 (100 ms timer) T16 to T32 (10 ms timer)

NC resource

Parameter

Statistic INT: DB4500.DBW0 to DB4500.DBW62 (32 double words)

Parameter

Statistic HEX: DB4500.DBB1000 to DB4500.DBB1031 (32 bytes)

Parameter

Statistic REAL: DB4500.DBD2000 to DB4500.DBD2028 (8 double words)

Programming

tool resource

SBR0 to SBR63 (64 subroutines)

SYM1 to SYM32 (32 symbol tables)

Data type Symbol Address

Loading...

Loading...