LC700- Manual de instalação

4.9

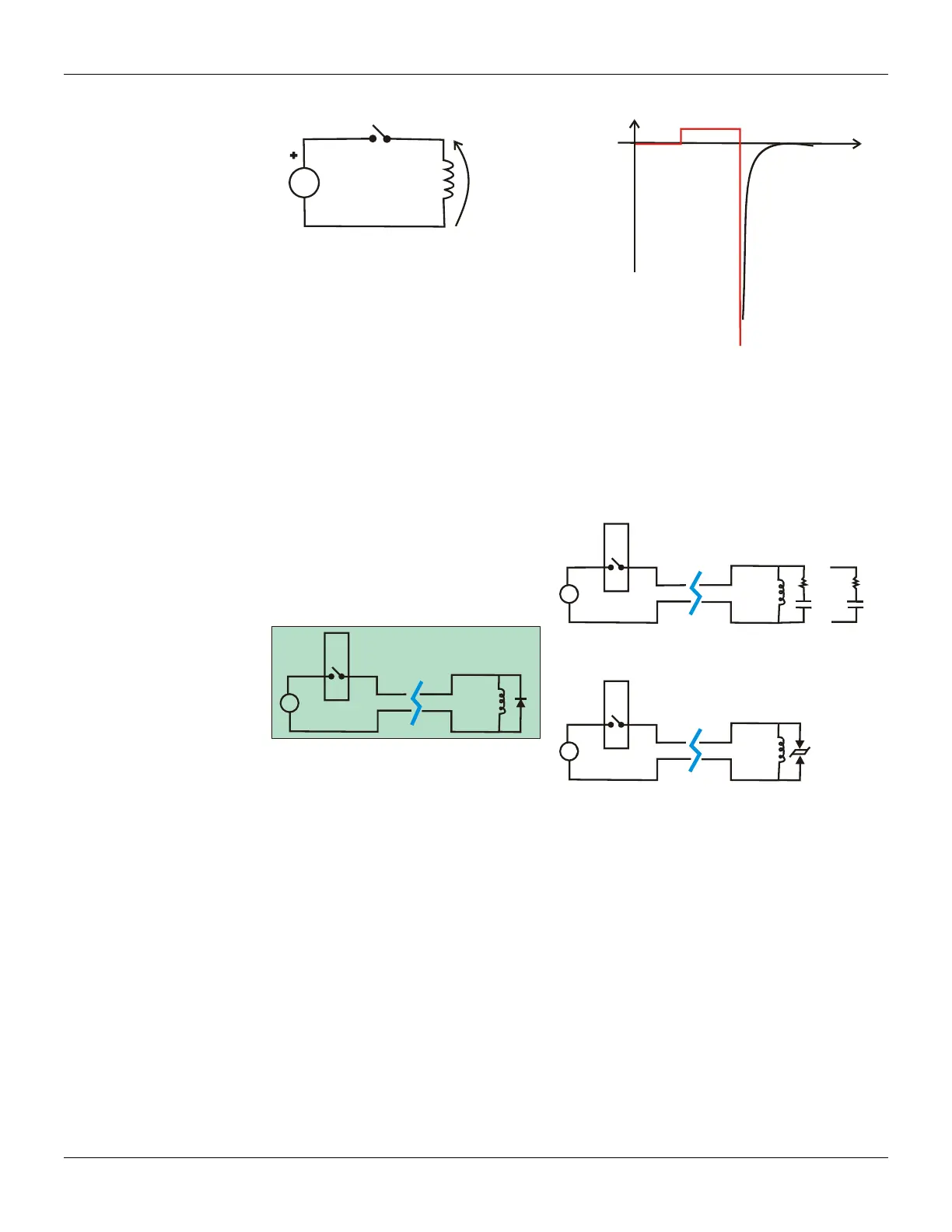

VL = L di/dt

Off

On

VL

Off

time

KV

VL

SW

L

DC

Figure 4.7 – Reverse Voltage Peak

Some alternatives may avoid this interference, like optical couplers, Zero Crossing Switching,

indirect startups that prevent the arrival of the noise to the command, but the noise generated by the

commuted device continues existing and many times it is induced in the wiring system, reaching

other automation electronic points, causing intermittent defects in the system. Therefore, those ways

of treating the noise are not effective. It should be eliminated exactly in the noise source, in other

words, in order to obtain a filter with better performance, it should be mounted the closest possible

to the commuted load.

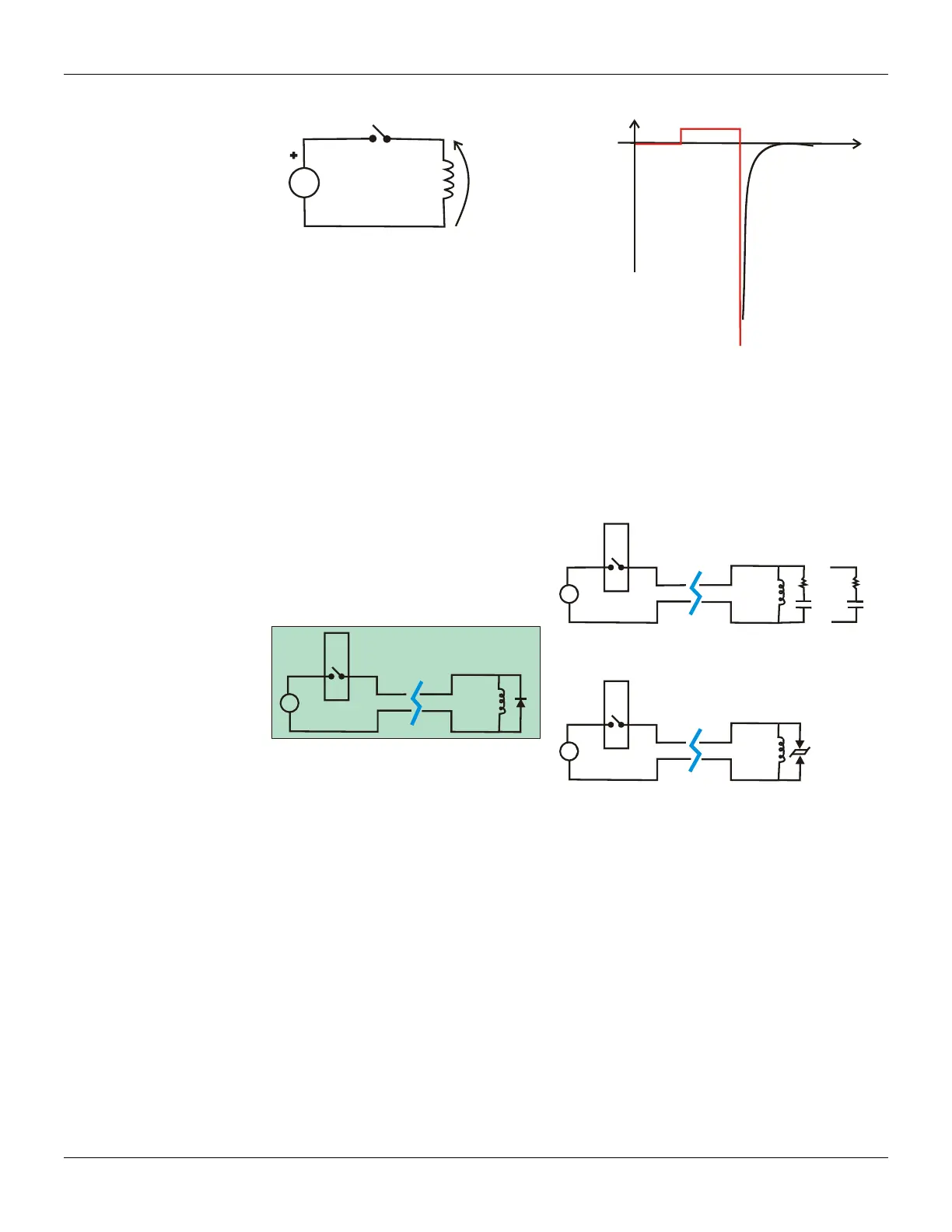

Relay Module

L

D

AC/DC

Relay Module

Relay Module

AC/DC

L

L

R

C

R

C

RC Networ

Transil / MOV

DC

Figure 4.8 – Filters for AC and DC loads

- Inductive Load: See the specification of each LC700 I/O module related to the circuit R-C

(snubber) and to the protection diode (campling):

- Inductive DC load: In spite of the LC700 digital output modules for the DC load having a

campling diode, it is recommended to insert other campling diode close to the inductive load.

This will avoid the noise coupling in other cables that are in the same conduit

Loading...

Loading...