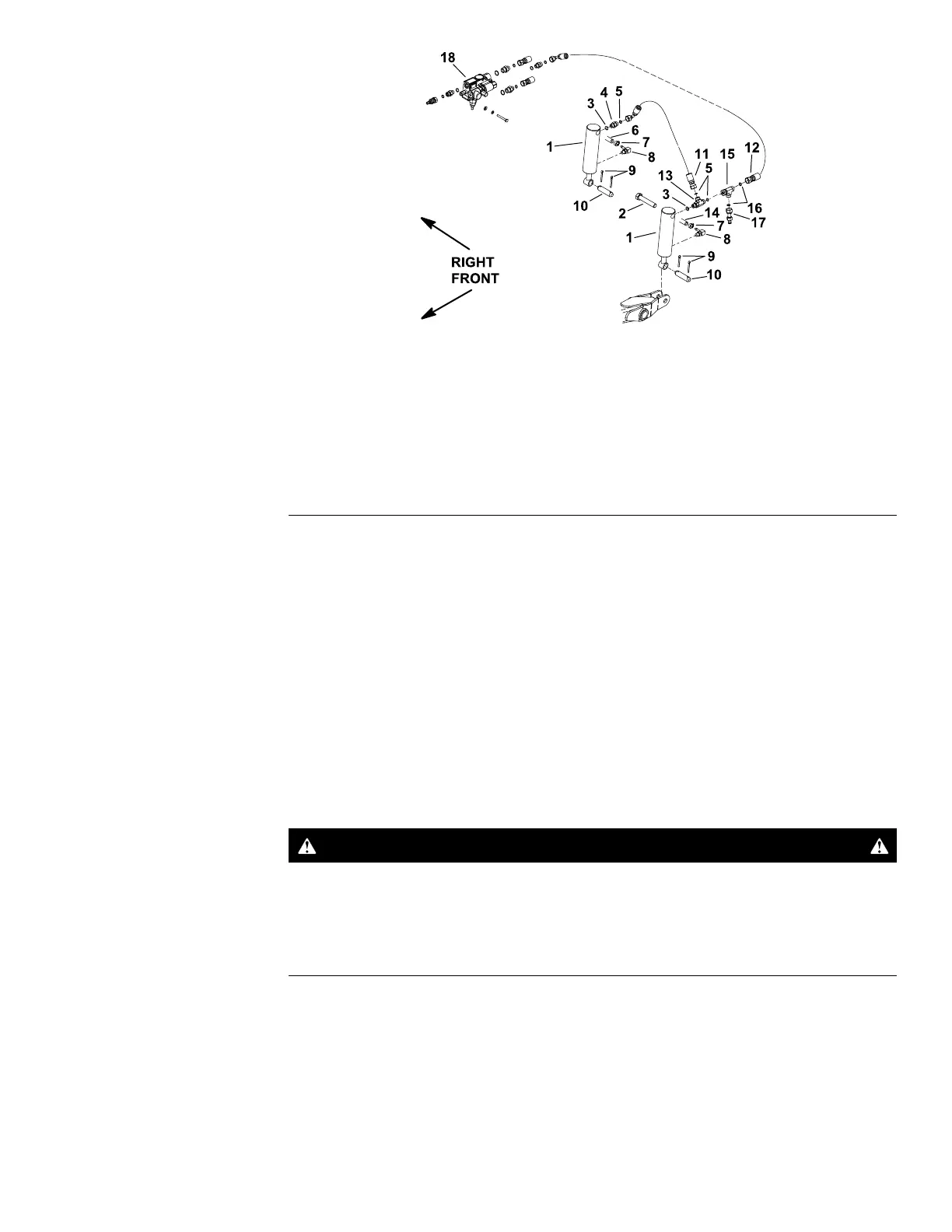

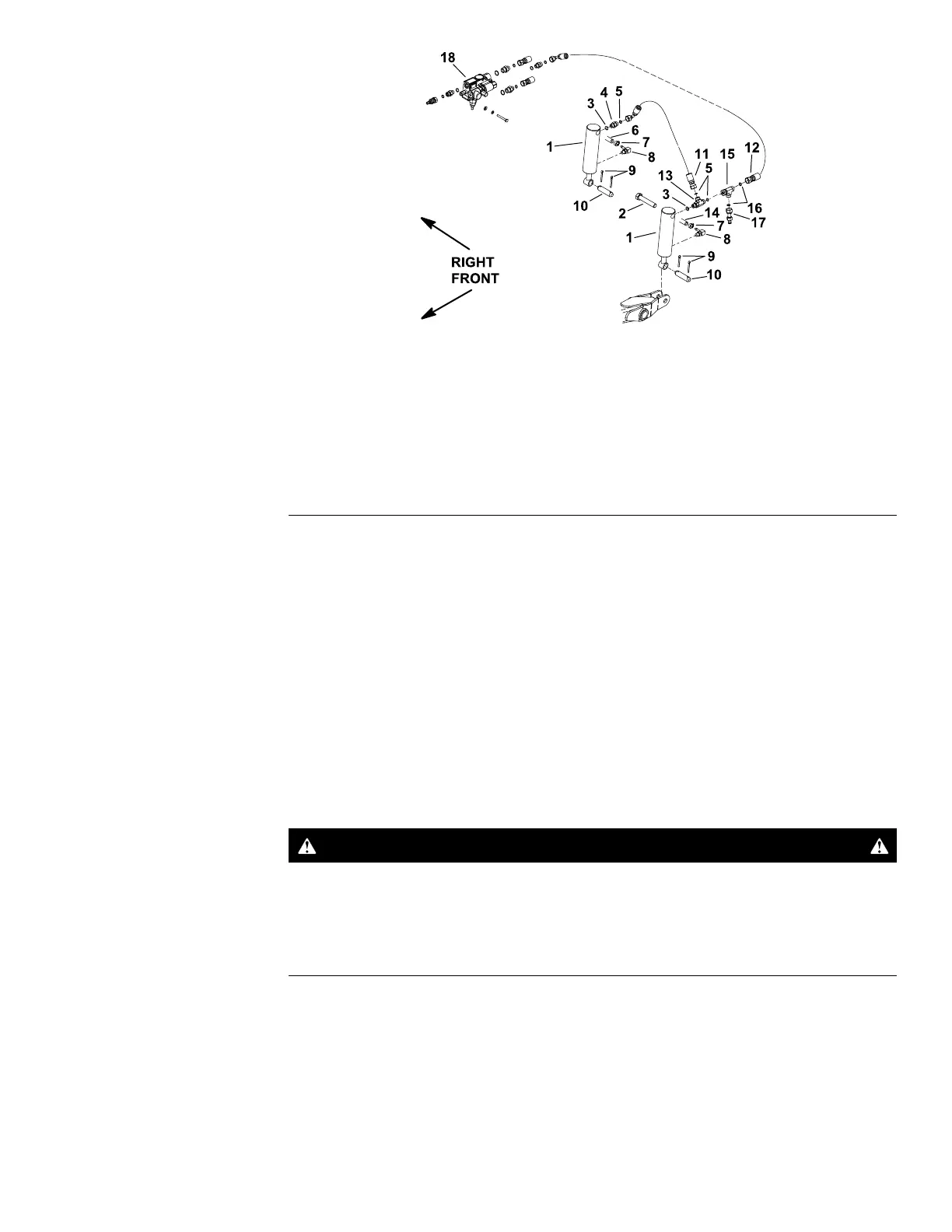

g230839

Figure93

1.Liftcylinder

7.Hoseclamp

13.Hydraulicteetting

2.Bolt8.Hosestem14.Hydraulichose

3.O-ring9.Cotterpin15.Hydraulicteetting

4.Hydraulictting10.Cylinderpin16.O-ring

5.O-ring

11.Hydraulichose17.T estport

6.Hydraulichose12.Hydraulichose

18.Liftcontrolvalve

Note:Iftheliftcylinderwearordamageoccurs,theliftcylinderreplacementis

necessary.Theliftcylindersarenotrebuildable.

Note:Onmachineswithserialnumbersabove260000001,thetestport(item

17inFigure93)islocatedontherightliftcylinder.

RemovingtheLiftCylinder

1.Parkthemachineonalevelsurface,lowerthecuttingdeck,shutoffthe

engine,settheparkingbrake,andremovethekeyfromthekeyswitch.

2.ReadtheGeneralPrecautionsforRemovingandInstallingtheHydraulic

SystemComponents(page5–77).

3.Forassemblypurposes,labelallthehydraulicconnections.Cleanthe

hydraulicconnectionsbeforelooseningthehydrauliclinesfromthelift

cylinder.

CAUTION

Beforeopeningthehydraulicsystem,operateallthehydraulic

controlstoreleasesystempressureandavoidinjuryfromthe

pressurizedhydraulicuid;refertoReleasingPressurefromthe

HydraulicSystem(page5–6).

4.Disconnectthehydraulichosesfromthettingsintheliftcylinderthatistobe

removed.Allowthehosestodrainintoasuitablecontainer.Removeand

discardtheO-ringsfromthettings.

5.Installcleancapsorplugsonthehydraulichosesandttingstoprevent

contamination.

6.Remove1cotterpin(item13inFigure92)fromthecylinderpin.Pullthe

cylinderpinfromtheliftcylinderandliftarm.

Groundsmaster

®

3280-D/3320

Page5–111

HydraulicSystem:ServiceandRepairs

05138SLRevB

Loading...

Loading...