AssemblingtheBladeSpindle(continued)

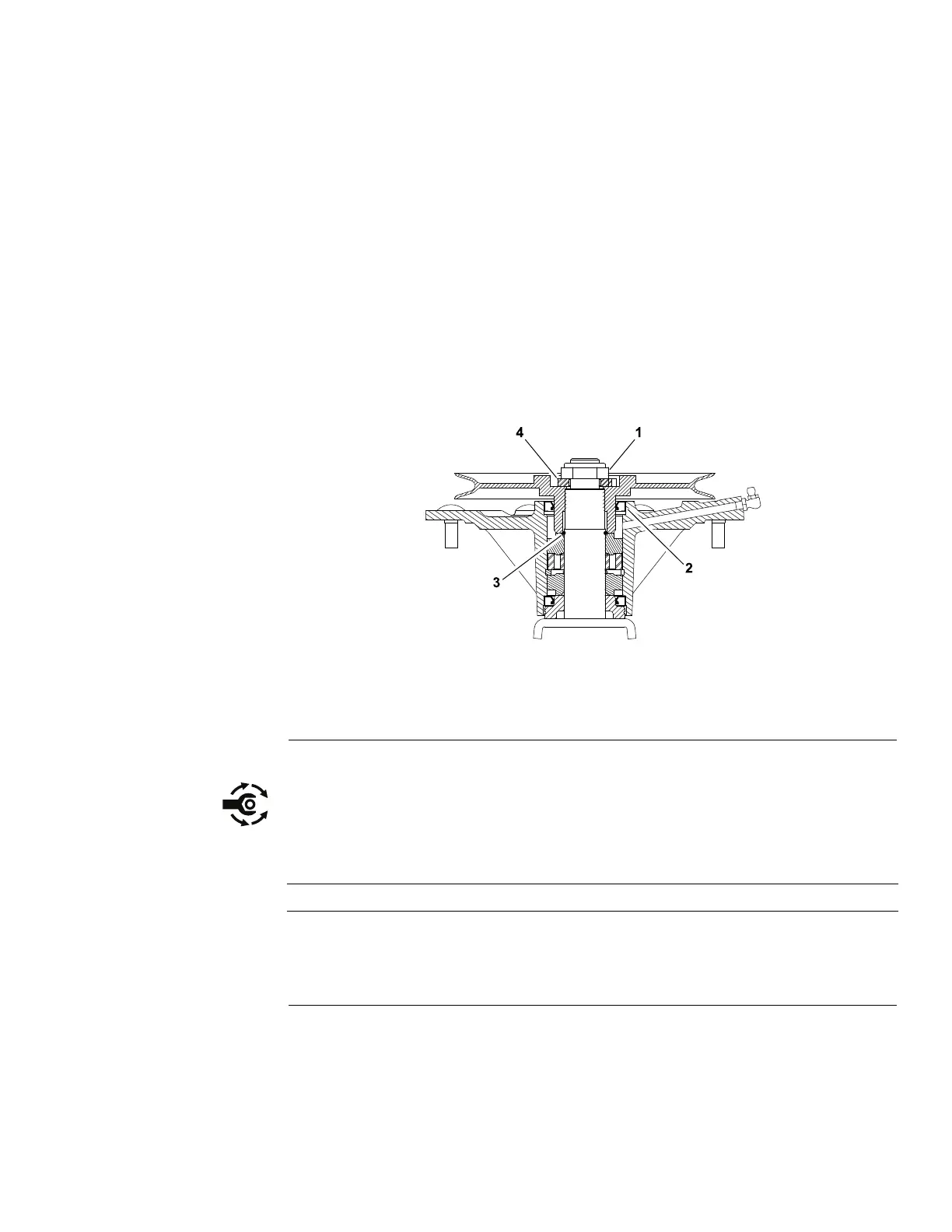

6.Slidethespacerringandinnerbearingspacerintothespindlehousing,then

installtheupperbearingconeandoilsealintothetopofthehousing.

Note:Theuppersealmusthavethelipfacingin(down).Also,installupper

sealsoitisushto1.5mm(0.060inch)recessedtothehousingsurface

(Figure301).

7.Examinethespindleshaftandshaftspacertoensurethattherearenoburrs

ornicksthatcoulddamagetheoilseals.Lubricatetheshaftandspacer

withgrease.

8.Installthespindleshaftspacerontotheshaft.Placeathinsleeveortapeon

thespindleshaftsplinestopreventdamageofthesealduringtheinstallation

oftheshaft.

9.Carefullyslidethespindleshaftwiththespacerupthroughthespindle

housing.

Note:Thebottomoilsealandspindlespacerttogetherwhenthespindle

isfullyinstalled.

g223666

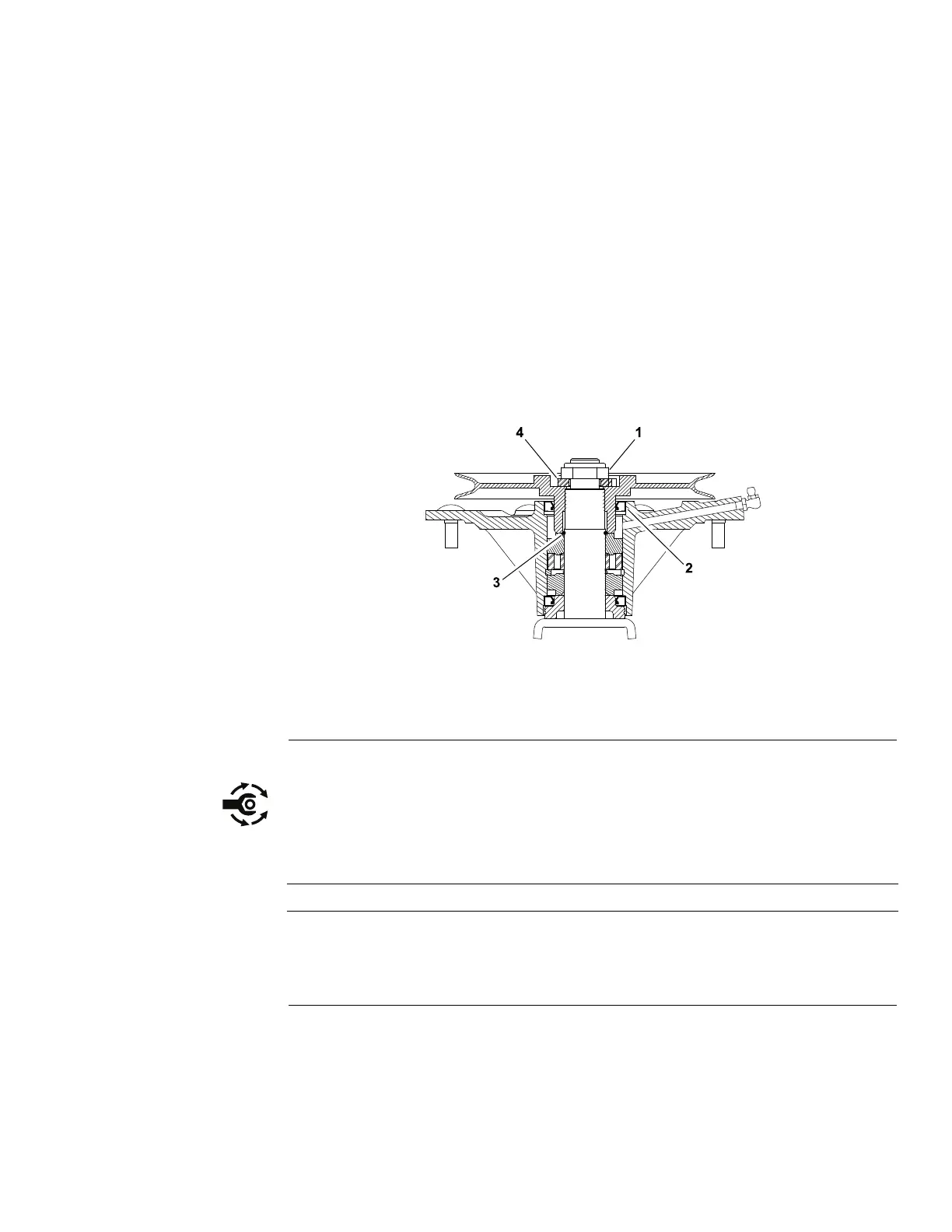

Figure302

1.Locknut

3.O-ring

2.Upperseal4.Hardenedwasher

10.InstalltheO-ringtothetopofthespindleshaft(Figure302).

11.Installthepulley(hubdown),specialhardenedwasher,andlocknuttothe

spindleshaft(Figure302);torquethelocknutto176to203N∙m(130to

150ft-lb).

IMPORTANT

Apneumaticgreaseguncanproducehighpressureinsidethe

spindlehousingthatcandamagethespindleseals.Thus,donotuse

apneumaticgreasegunforgreasingofthespindlehousings.

12.Attachahandpumpgreaseguntothegreasettingonthehousingandll

thehousingcavitywithgreaseuntilthegreasestartstocomeoutofthe

lowerseal.

13.Rotatethespindleshafttoensurethatitturnsfreely.

Groundsmaster

®

3280-D/3320

Page10–13

CuttingUnits:ServiceandRepairs

05138SLRevB

Loading...

Loading...