AssemblingtheBladeSpindle(continued)

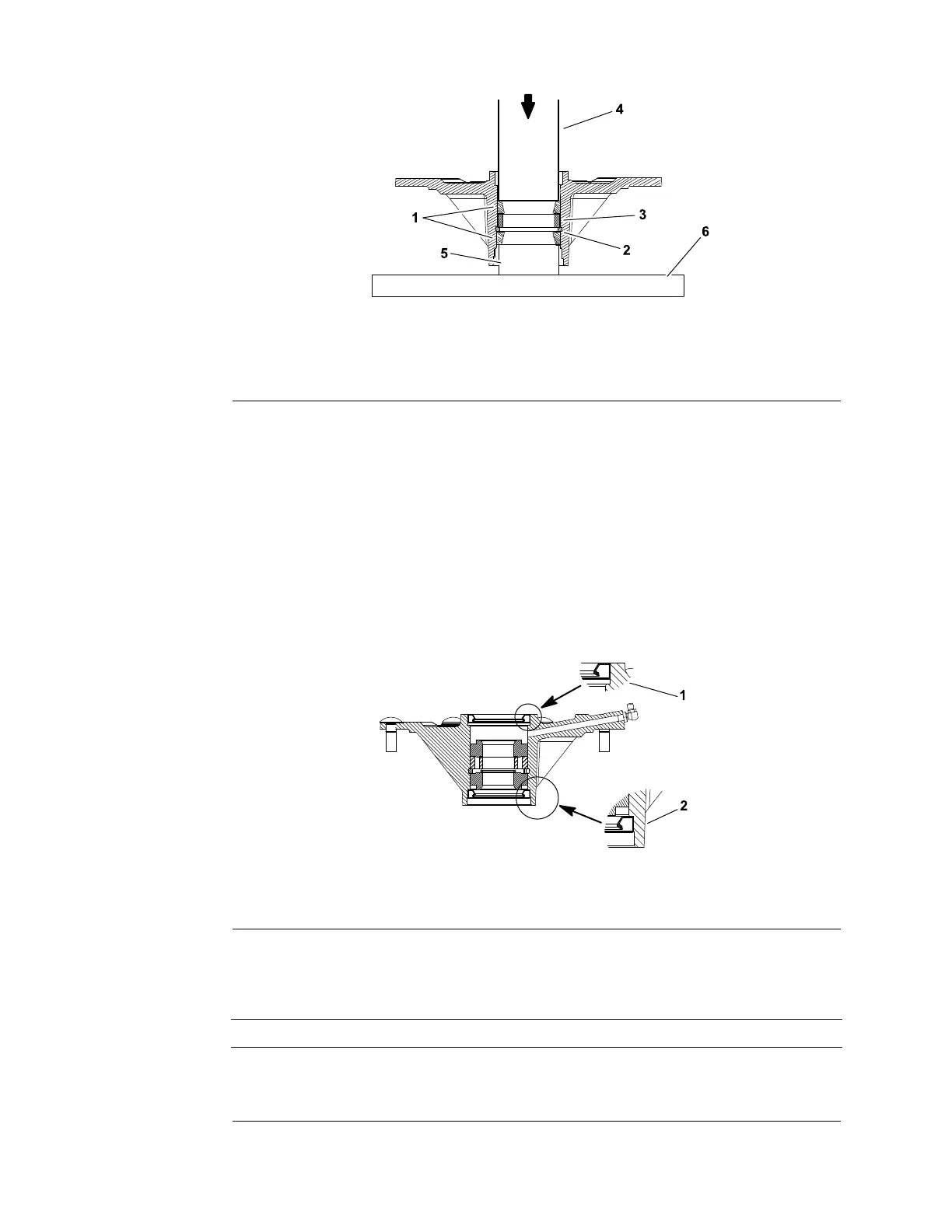

g223664

Figure300

1.Bearingcup

3.Outerspacer5.Support

2.Largesnapring4.Arborpress6.Arborpressbase

3.Useanarborpresstopushthebearingcupsintothetopandbottomofthe

spindlehousing(Figure300).

Note:Thetopbearingcupmustcontacttheouterspacerthatwaspreviously

installed,andthebottombearingcupmustcontactthesnapring.

Note:Ensurethattheassemblyiscorrectbysupportingtherstbearingcup

andpressingthesecondbearingcupagainstit.

4.Packthebearingconeswithgrease.Applyalmofgreaseonthelipsofthe

oilsealsandO-ring.

5.Installthelowerbearingconeandoilsealintothebottomofthespindle

housing.

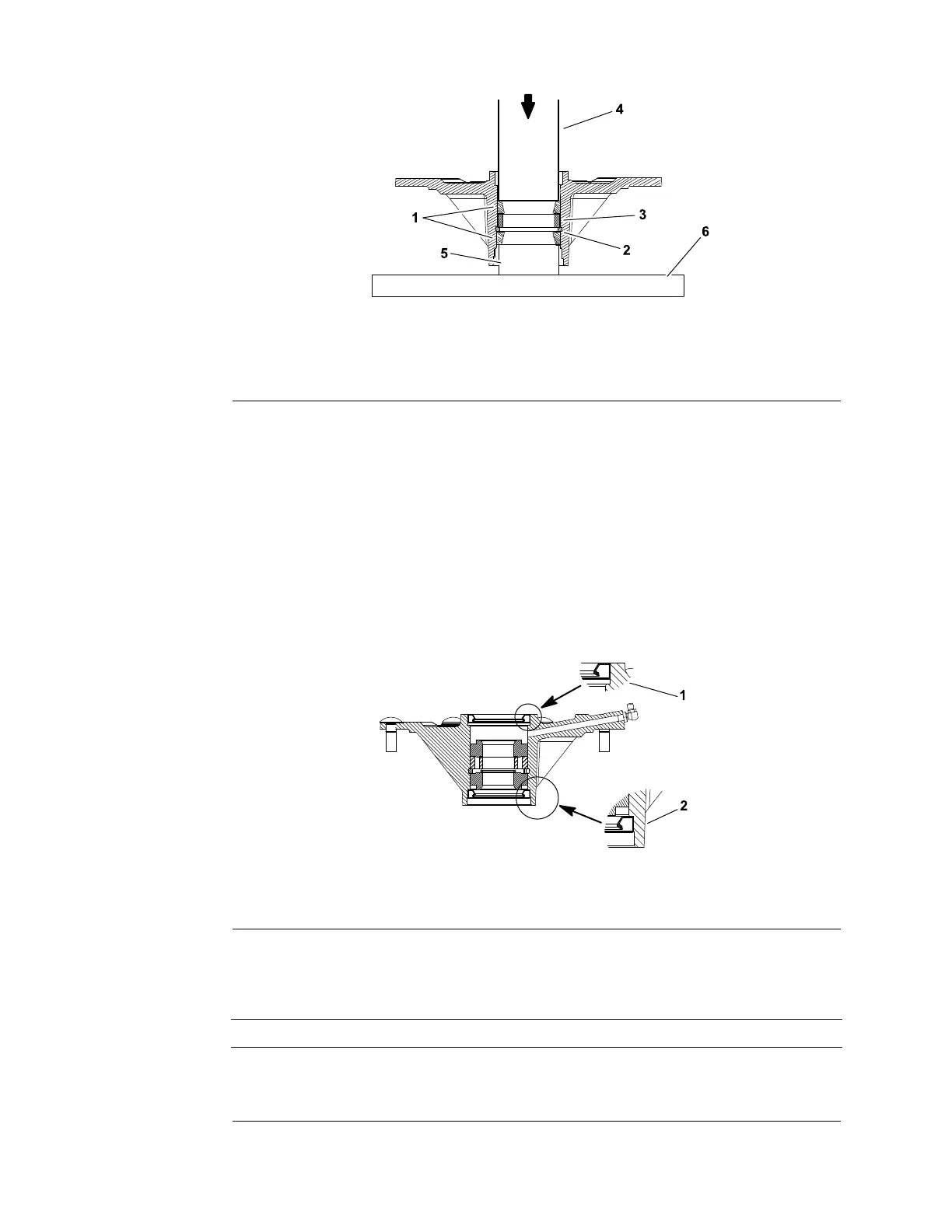

g223665

Figure301

1.Uppersealinstallation2.Bottomsealinstallation

Note:Thebottomsealmusthavethelipfacingout(down).Thisseal

installationallowsgreasetopurgefromthespindleduringthelubrication

process(Figure301).

IMPORTANT

Ifyouarereplacingthebearings,ensurethatyouusethespacerring

thatisincludedwithanewbearingset(Figure299).

CuttingUnits:ServiceandRepairs

Page10–12

Groundsmaster

®

3280-D/3320

05138SLRevB

Loading...

Loading...