SHB WL34 * 2.0 8-17

Work hydraulics 8

Lifting cylinder

8.9 Removing/installing the lift cylinder

Preparing work

Tools:

• Suitable lifting tackle with a carrying capacity of at least 30 kg

• Suitable receptacle for collecting the hydraulic oil

• Plugs (different sizes) for closing the oil lines

Technical data

Use a suitable container to collect the hydraulic oil as it drains off and

dispose of it in an environmentally friendly manner!

Injury hazard due to heavy component.

The lift cylinder weighs approx. 25 kg.

► To remove and install the lift cylinder, use suitable lifting gear or work

together with a second person.

Compensation rings can be on both sides of the bearings to reduce play

and avoid damage.

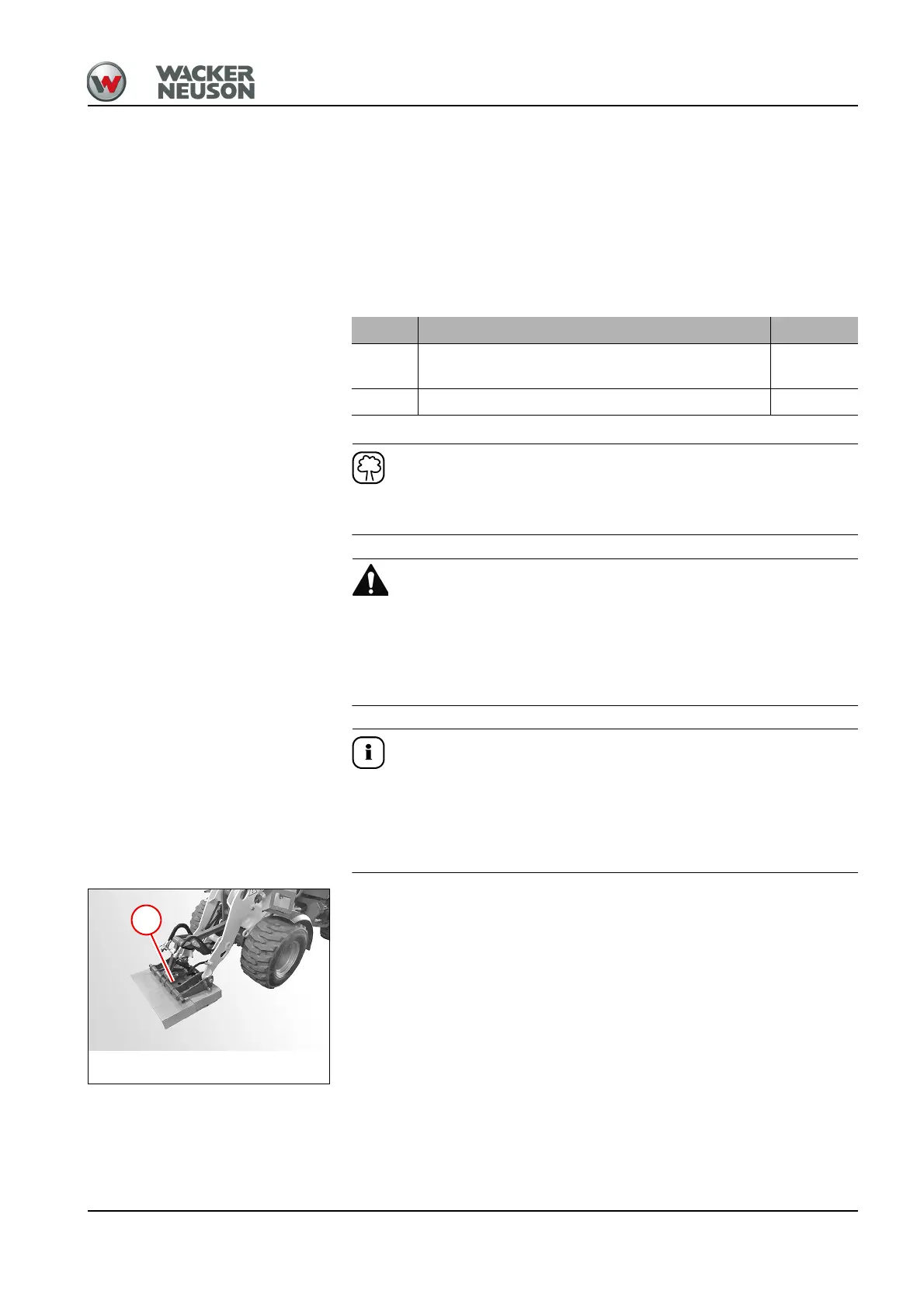

This section describes the replacement of a lift cylinder. The second lift

cylinder is replaced in the same way.

1. Reduce the load on the loader unit by lowering the quickhitch 1 to the

ground.

Designation Weight

A20

Lift cylinder without counterbalance valve (stan-

dard)

21.1 kg

A68 Lift cylinder with counterbalance valve 24.7 kg

Work hydraulics

Lifting cylinder

Loading...

Loading...