Perform main diagnostic tests

July 29, 2013, 715003794 Rev. B 227

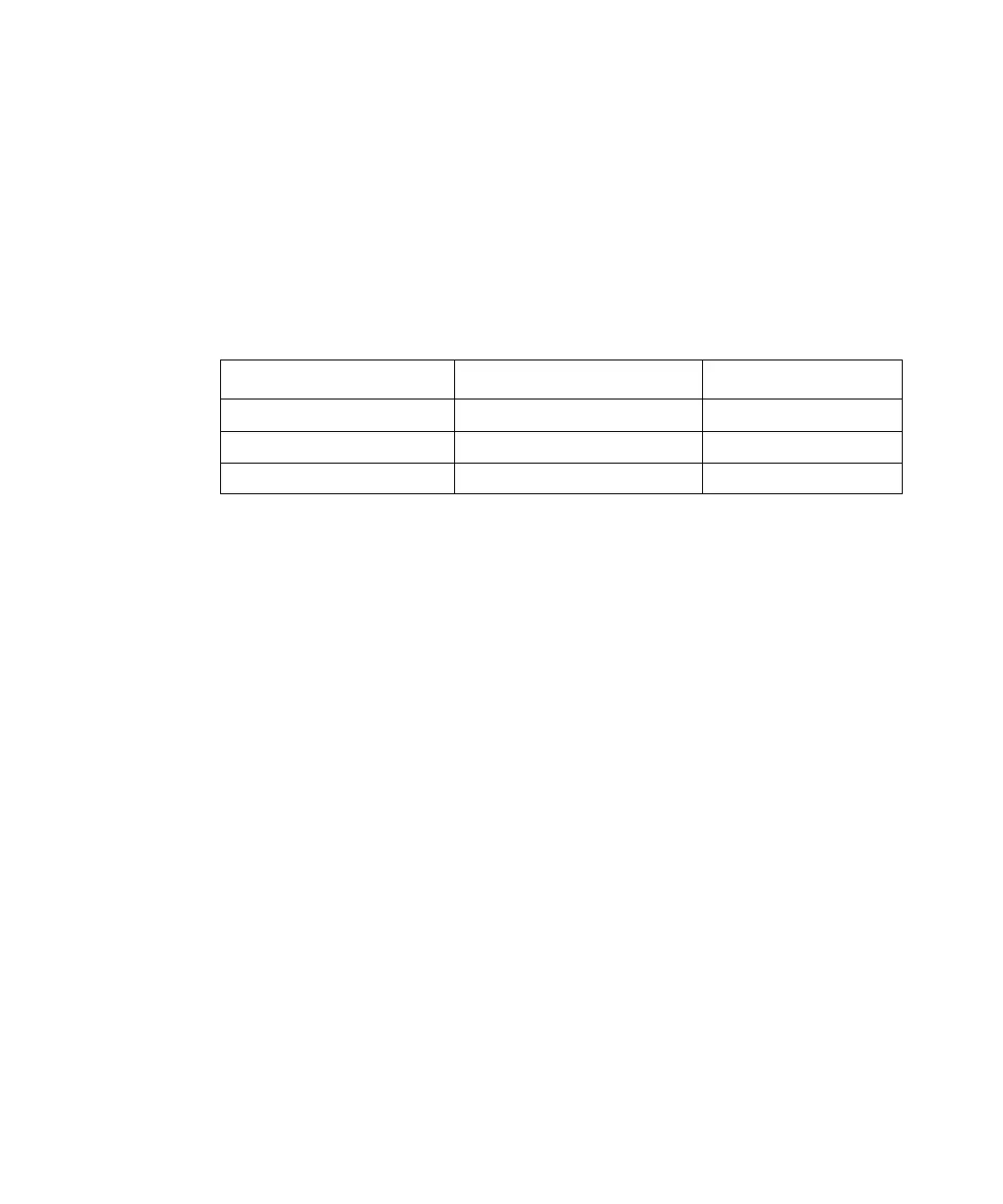

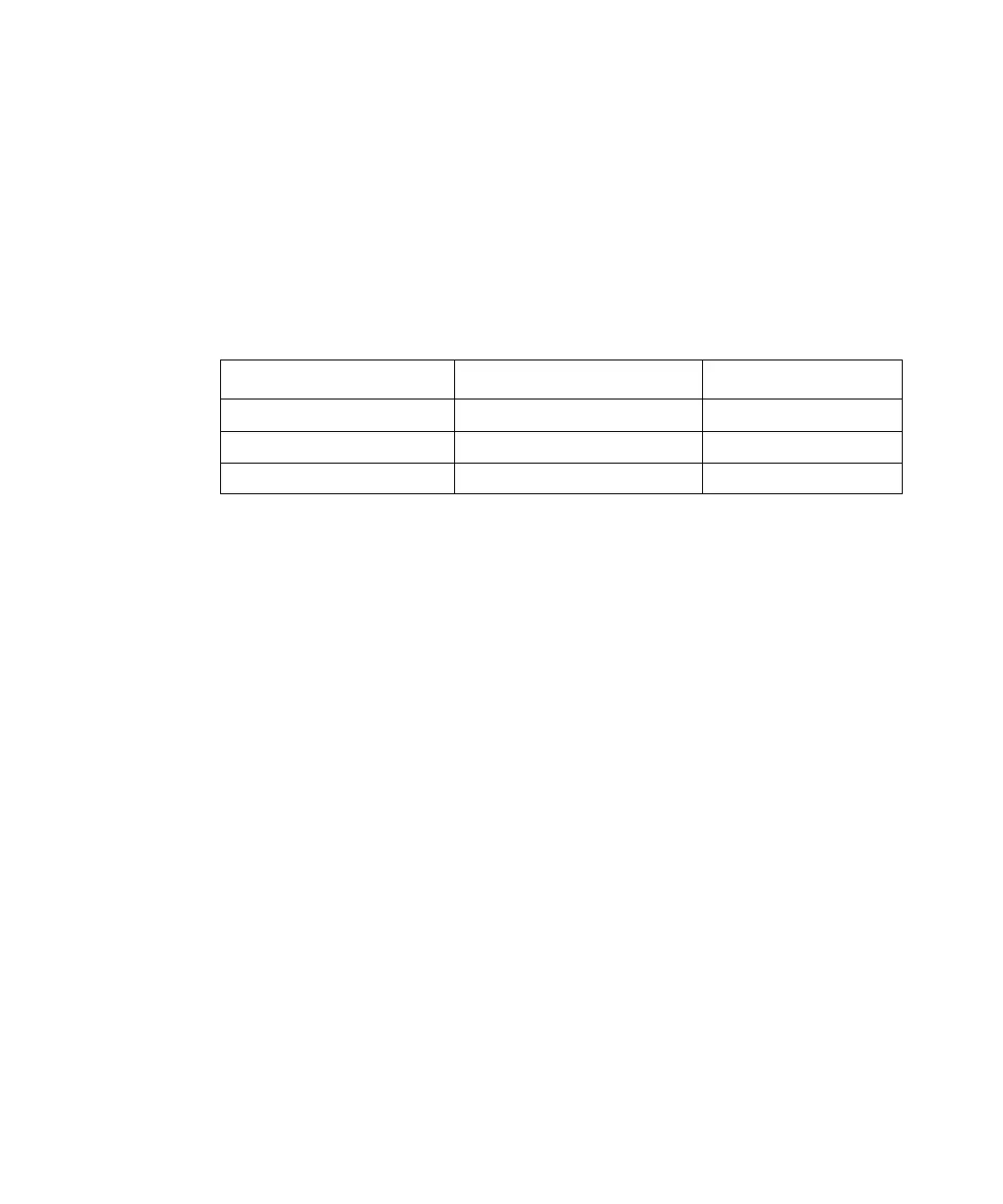

Confirm the seal data values—top, bottom, and width—fall within the

acceptable ranges shown in the table, below. A seal geometry error can appear

if these conditions apply:

• The adjust seals parameter values are not in the acceptable range.

• Air bubbles occur in the sample management system. (If so, purge the

sample management system and try again.)

• Solvent is not properly degassed (even though air bubbles are not

visible).

Adjust seals failure

To correct for a failing result on the adjust seals test:

1. Confirm that the flow rate for the adjust seals test was set to 1.0 to 1.5

mL/min, the 100% methanol was properly degassed and filtered, and

that degassing was enabled.

2. If all the conditions in step 1 are satisfied, proceed to step 3.

If any conditions in step 1 are not satisfied, correct it (or them), and then

repeat the test.

Requirement: If the test fails again, proceed to step 3.

3. Replace the restrictor in the red outlet line with a pin plug.

4. Ramp system pressure up to 31026.4 kPa (310.3 bar, 4500 psi); hold this

pressure for 2 minutes.

5. Repeat the adjust seals test.

6. If the test fails again:

a. Stop solvent flow.

b. Monitor the displayed pressure value (which must be stable and

approaching zero).

Acceptable ranges for the adjust seals diagnostic test:

Parameter Acceptable range Typical range

Top 30 to 80 30 to 60

Bottom 80 to 200 120 to 150

Width (Bottom–Top) 50 to 120 60 to 90

Loading...

Loading...