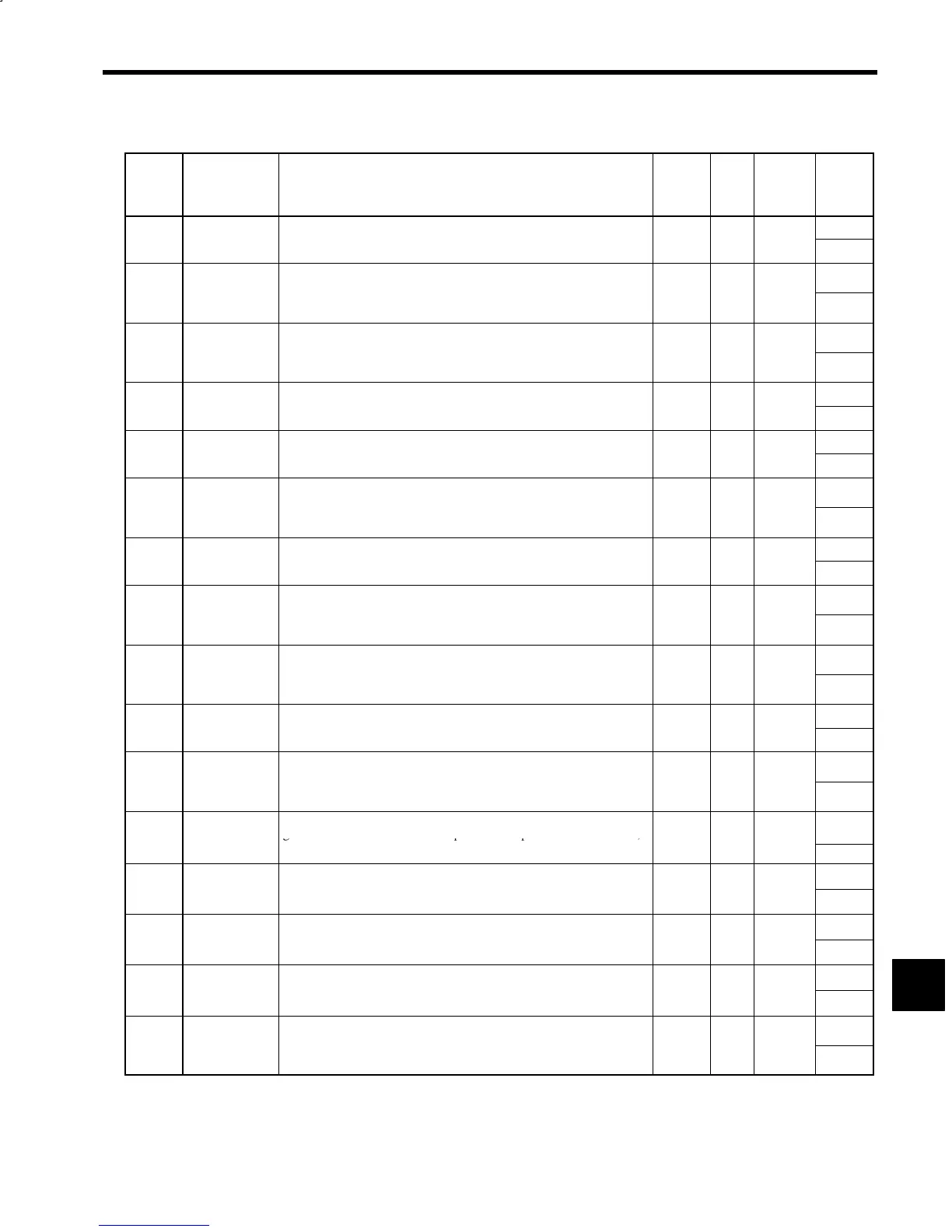

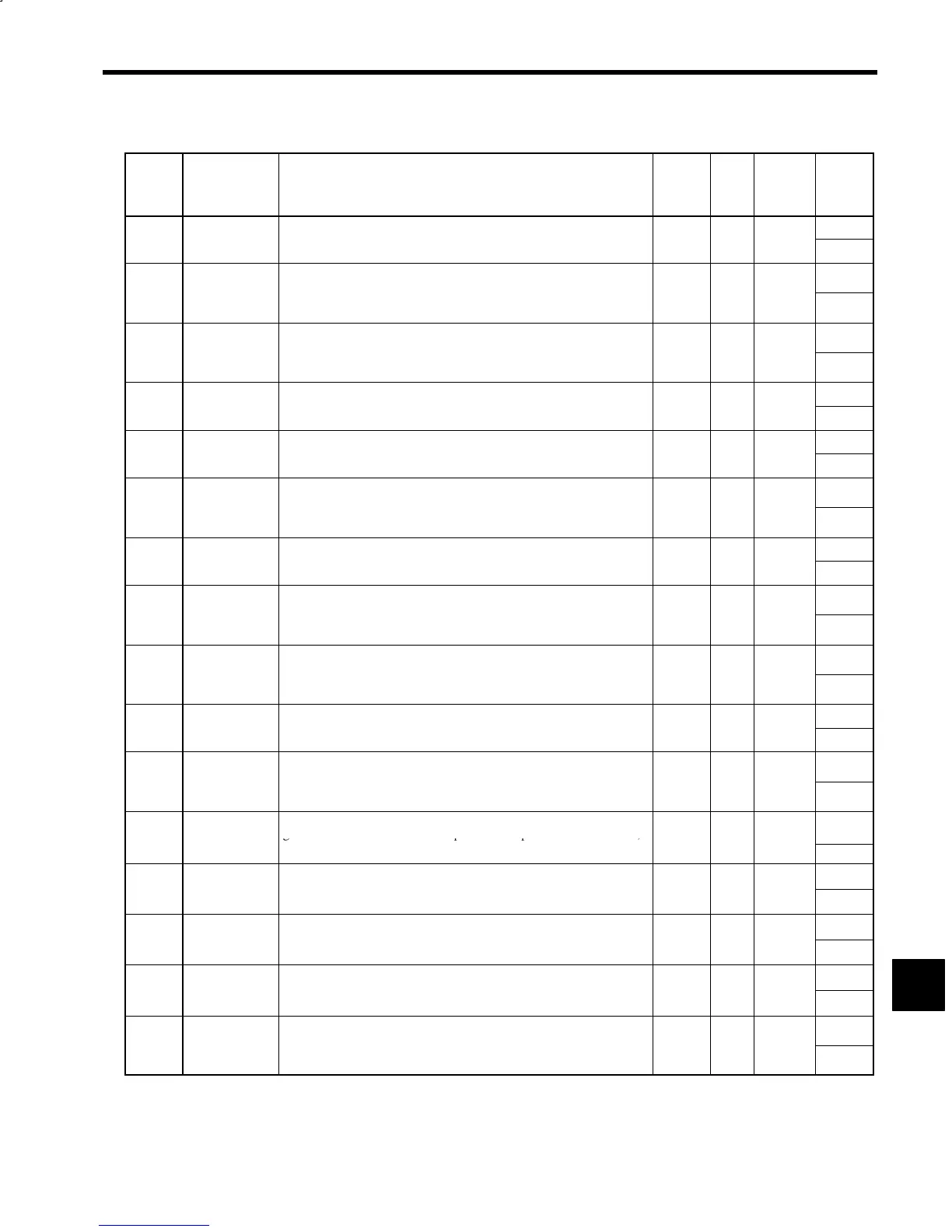

10.1 User Constants

10-3

Table 10.1 User Constants (continued)

Con-

stant

No.

Name Explanation Change

*

1

Unit Standard

Setting

Upper

Limit/

Lower

Limit

C1-13

--- ---

---

to

C1-15

--- --- ---

---

*

Speedometer

Si

nal Ad

ust-

Constant to finely adjust the speed signal so that the actual speed and

s

eedometer dis

la

a

ree. When the value of SM

ADJ

increases,

1.50

C1-16

ment Value

SM

ADJ

.

,

speedometer indication also increases. A 10-V output is the standard

value at rated speed (C1-26).

Yes --- 1.00

0.90

*

Load Meter Sig-

nal Ad

ustment

This constant makes fine adjustments so that the torque reference and

the load meter dis

la

a

ree. When the value of LM

ADJ

increases, meter

1.50

C1-17

Value

LM

ADJ

.

,

needle indication also increases. A 10-V output is the standard value at

120% of rated torque for 30 min.

Yes --- 1.00

0.90

*

Load Factor

Sets the load meter full scale value when continuous torque is taken to

500

C1-18

Meter Fu

Sca

e

LM

FS

e 100

.T

efu

sca

eva

ue

epen

s on mac

ne spec

f

cat

ons.

Yes % 200

120

Zero Speed

Detection level of zero-speed signal (ZSPD). Standard setting is 30

−1

−

60

C1-19

Detect

on Leve

ZS

LVL

m

n

−

.

Yes min

−

30

3

Speed Agree

Si

nal Detection

Detection width of speed-agree signal at rated speed. Standard setting is

15%.

50

C1-20

Width

AGR

BD

.

Yes % 15

10

Speed Detection

Speed detection signal (SDET) activation level used for winding selec-

100

C1-21

S

gna

Leve

SD

LVL

t

on. Expresse

as a percent of t

e motor rate

spee

C1-26

.

Yes % 10

0

Speed Detection

Si

nal Detection

Hysteresis width adjustment level of speed signal detection. During

acceleration, SDLVL + SDHYS is detected. Durin

deceleration,

10.00

C1-22

Width

SD

HYS

,

.

,

SDLVL − SDHYS is detected. Expressed as a percent of the motor rated

speed (C1-26).

Yes % 1.00

0.00

Torque Detec-

tion Si

nal O

-

Torque detection signal (TDET) activation level used to detect abnormal

loads. Ex

ressed as a

ercent of the 30-minute rated tor

ue. H

steresis

120

C1-23

eration Level

TD

LVL

.

.

width is limited to ±10%.

Yes % 10

5

External Control

Torque limit using external torque limit signals (TLL and TLH).

120

C1-24

Torque L

m

t

Level TL

EXT

Expresse

as a percent of t

e 30-m

nute rate

torque.

Yes % 10

5

Motor Code

Selection MTR

Select applicable motor from the motor codes stored in Inverter memo-

r

.Ex

ressed in 3-di

it hexadecimal

0toF

. When the motor code is

1FF

C1-25

.

.

changed, be sure to turn OFF the power once; and then turn it ON again

after verifying that the Digital Operator display has gone OFF.

No --- ---

001

C1-26

Rated Speed

S

100

Rated speed set according to load machine specifications. Must not be

greater than the motor maximum speed. When speed reference is 100%,

No min

−1

Max.

Max.

speed

this speed is applied.

speed

100

Gear Ratio 1

Gear ratio determined by mechanical specifications. This parameter is

2.5000

C1-27

R

HGR

va

w

en

gear

sse

ec

e

.e.,

an

are

.

Gear ratio = Load shaft speed ÷ Motor speed

No --- 1.0000

0.0400

Gear Ratio 2

Gear ratio determined by mechanical specifications. This parameter is

2.5000

C1-28

R

MGR

va

w

en

gear

sse

ec

e

.e.,

s

.

Gear ratio = Load shaft speed ÷ Motor speed

No --- 1.0000

0.0400

Gear Ratio 3 (L)

Gear ratio determined by mechanical specifications. This parameter is

2.5000

C1-29

LGR

va

w

en

gear

sse

ec

e

.e.,

s

.

Gear ratio = Load shaft speed ÷ Motor speed

No --- 1.0000

0.0400

Motor Flux

Lower Limit

Set value of motor flux lower limit level at reduction control

100

C1-30

Level

φ

WL

No % 15

15

10

Loading...

Loading...