2 Options & Parameters

Mk8 MM Manual Page | 58

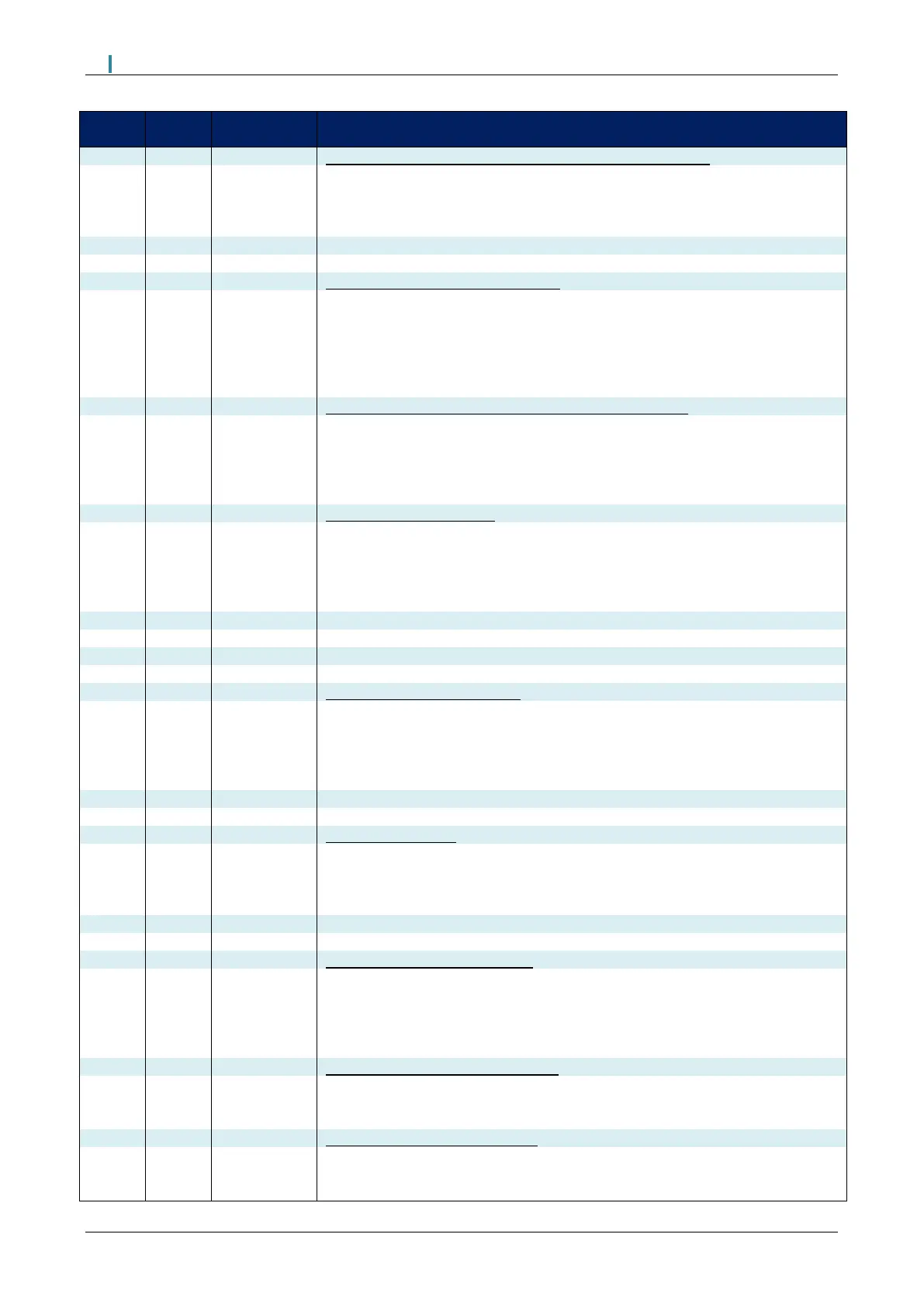

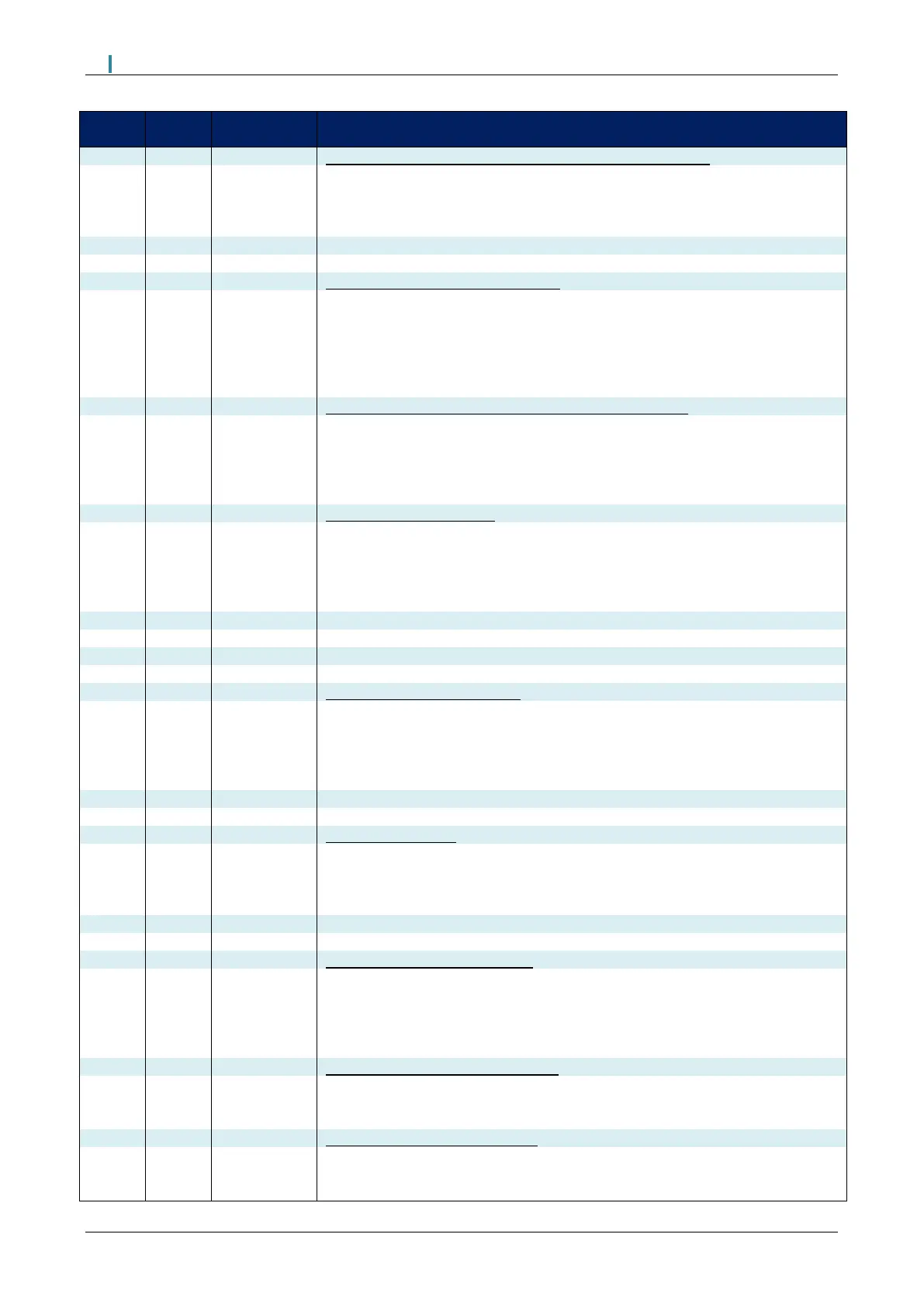

Par.# Default Range Description

DTI: Sequence Scan Time Set When Units Goes Offline

If a sequenced MM drops out of the sequence loop, there is a time delay

before the next scan time.

DTI: Number of Boilers Initially On

This sets the number of boilers which when powered on after a shutdown,

are in the On state in the sequence loop. This set should be set to the

highest MM ID number (see parameter 57) if the application requires all

the MMs to be On in the sequence loop when powered back on.

EGA: Delay Before EGA Commission Can be Stored

During commission and single point change, there is a delay before the

EGA values are stored. This value should be set in proportion to how long

it takes for the gases to reach the EGA

If a sequenced MM does not start modulating after being asked to by the

lead MM, it is ignored in the sequencing loop. Upon the next scan time, if

the MM modulates as required, it will be included in the sequencing loop.

EGA: Trim Delay After Drain

This is the delay after draining the sample, before the trim cycle start.

Within this delay, the trim correction on the air damper or VSD is

maintained while the EGA drains and the cells are purged with air.

Mk7 - For use with Mk7 EGA

Mk8 Protocol (Legacy) – For use with Mk8 EGA

Mk8 Protocol (RS485) – For use with Mk8 EGA EVO

EGA: CO Used for Trim on Oil

If the fuel has been set as oil (see options/ parameters 150 to 153), then

the trim function can include CO to calculate the required trim correction.

EGA: Commission Fuel-Rich Trim

The % of air damper movement when commissioning fuel-rich trim.

EGA: Trim Reset Angular Rate

This is the change time in the fuel valve angle per minute that will reset the

trim correction.

0.0 – 90.0 degrees per minute

Loading...

Loading...