7/9

Chapter 7: Maintenance

Operators & Maintenance Manual GENIUS Compact Version UK 0.1 © BESTnv

BESTnv Industrial Research BV, Marinus van Meelweg 20, 5657 EN, EINDHOVEN, THE NETHERLANDS

General tel. +31 (40) 292 2622 - Service tel. +31 (40) 292 2620 - Fax. +31 (40) 292 2633 - Email: service.BESTnv@bestnv.com

7.5. The Detection Belt

7.5.1. General

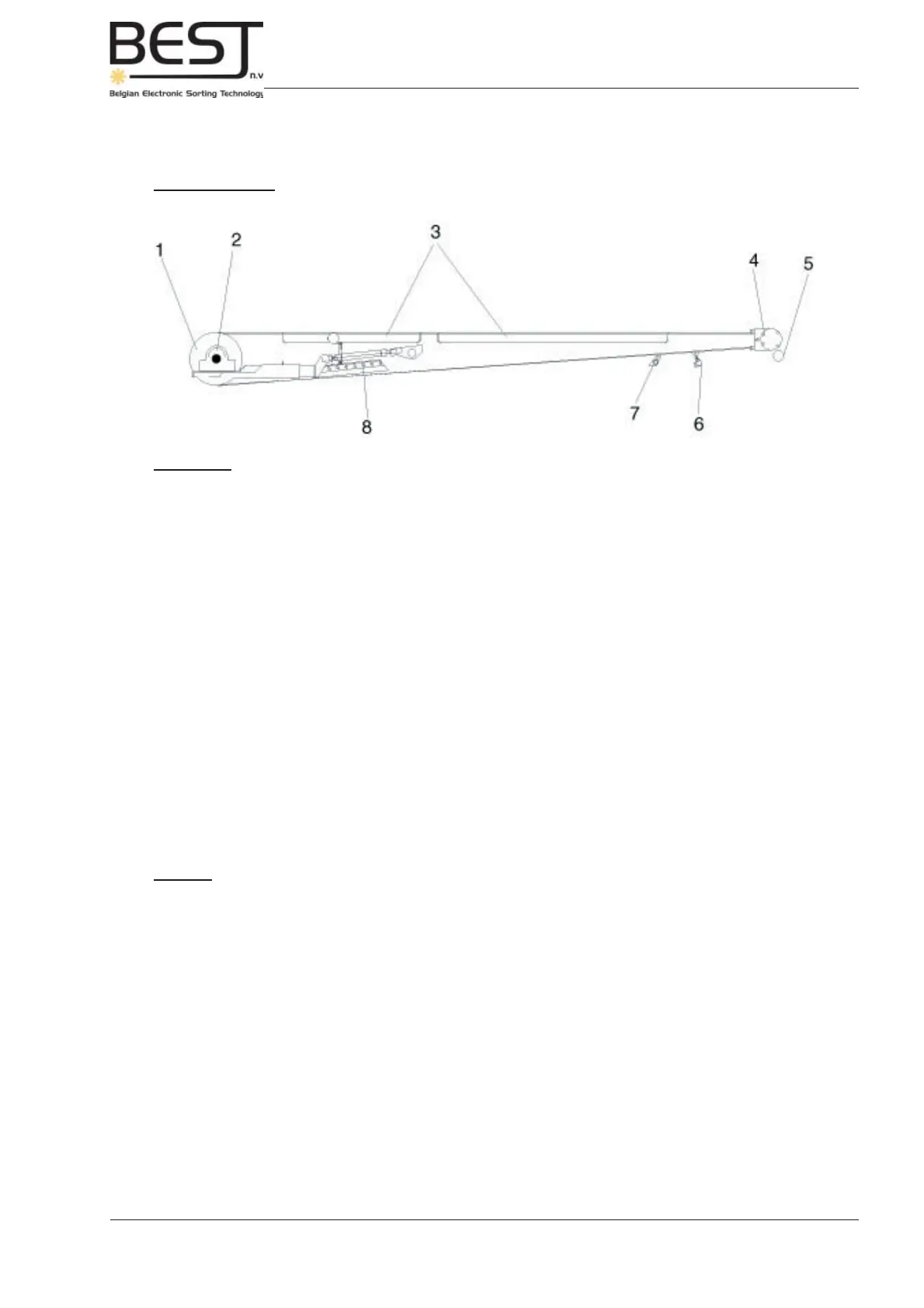

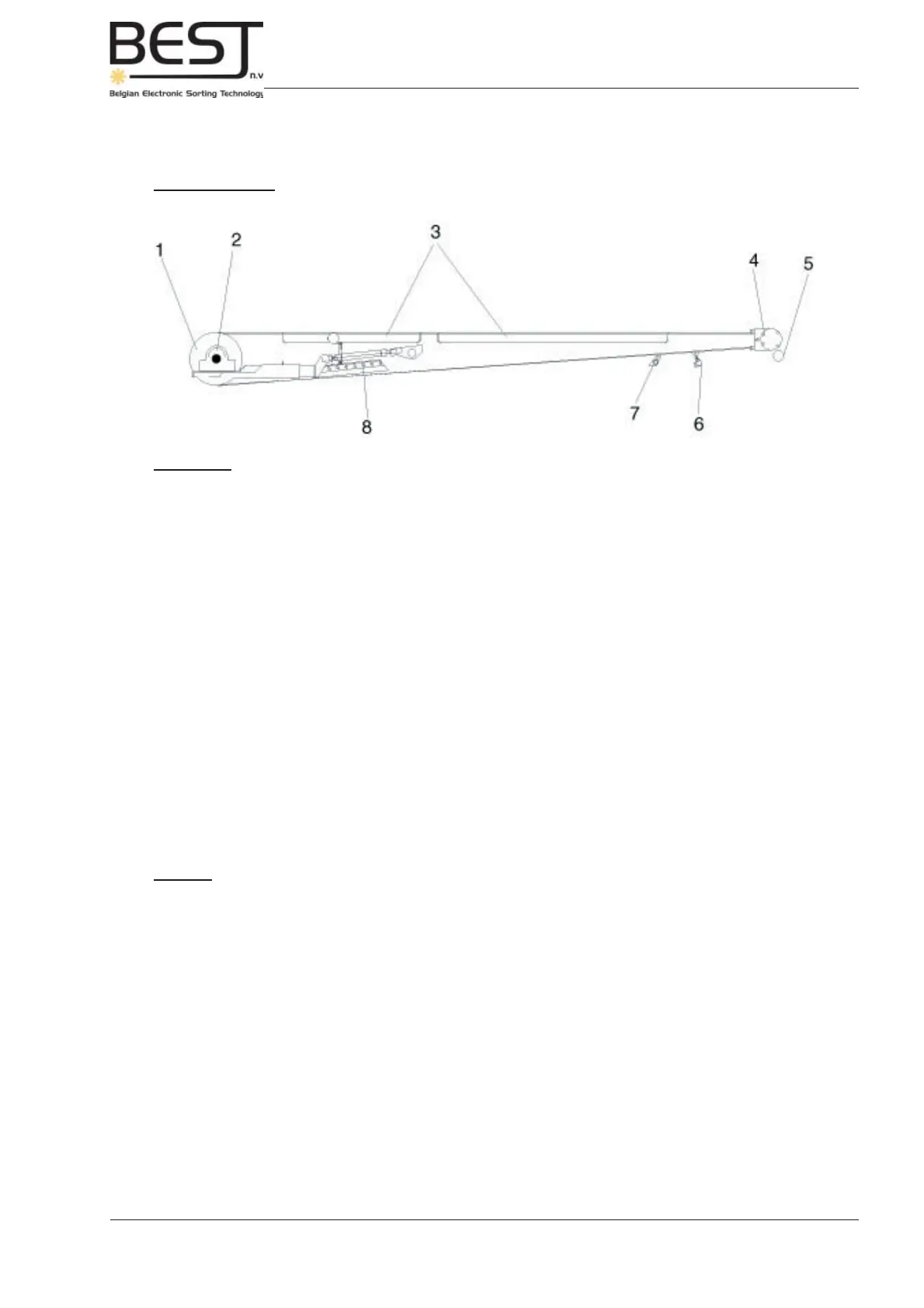

Schematic

The detection belt consists of a wide fl at belt (640 or 1200 mm) of a specifi c colour chosen in function of

the products to be sorted. It is driven by a reductor motor that rotates the drive drum (1). The upper part

of the belt runs from the drive drum over gliding plates (3) to the return station (4), and the lower part

goes straight back to the drive drum.

To keep the belt clean during the sorting process the system has been equipped with an optional water

spray system (6). To remove any sticky product or objects, an outside scraper (7) and a v-shaped inside

scraper (8) have been added. During operation one should regularly check that the scrapers - inside and

outside - really do touch the belt, but are not pressed too tightly against the belt (for this could damage

the belt and thus affect the sorting effi ciency).

The return station (4) may consist of a large or a small return axle. The choice of return station is

determined by the shape and the properties of the products that are to be sorted. Large or small return

axle makes absolutely no difference when tensing or tracking the detection belt. Keep in mind that the

return station is always fi xed to the frame, so any adjustments for tensing and/or tracking will have to be

done by adjusting the position of the drive drum.

If the GENIUS Compact sorter unit is equipped with a laser box, a background drum (5) will be added

to the confi guration.

General

Remember that correct tensing and tracking is very important for any kind of belt (including return system,

accept and/or reject belts). If the belt is under enough tension it will start slipping and will not function

properly. However, if it is under too much tension, this will damage and decrease the lifetime of not only

the belt itself, but also of the bearings of the belt system.

It is also important to regularly grease the bearings of all rotating elements, including drive drum, return

axles, background drums/reference rollers (laser box option), light tubes (FSV-option), etc... For more

info, check greasing procedure later in this chapter. The return axle of the detection belt is greased for

life and should not need any maintenance.

Loading...

Loading...