3/9

Chapter 3: Theory

Operators & Maintenance Manual GENIUS Compact Version UK 0.1 © BESTnv

BESTnv Industrial Research BV, Marinus van Meelweg 20, 5657 EN, EINDHOVEN, THE NETHERLANDS

General tel. +31 (40) 292 2622 - Service tel. +31 (40) 292 2620 - Fax. +31 (40) 292 2633 - Email: service.BESTnv@bestnv.com

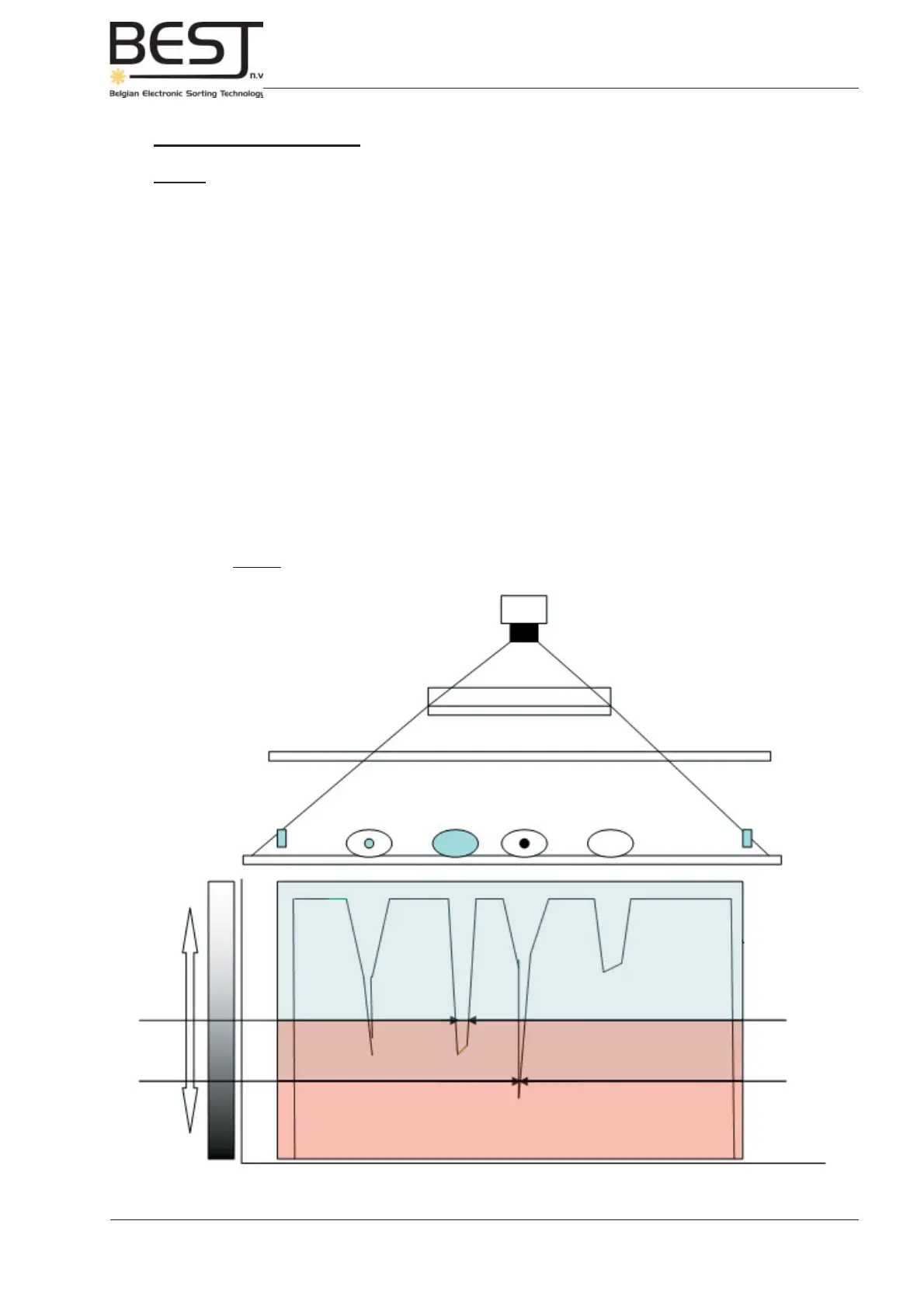

Picture: Theory of detection system: standard setup with 2 low thresholds

Camera

2048 pixels

Mirror

Illumination:

HF-lights or LED-lighting

Product

guidance strip

Belt

0

255

White

Black

1 PIXEL 2048 PIXELS

Normalized

signal

ACCEPT RANGE

Threshold 1 size 2:

lighter and bigger defects

Threshold 2 size 1:

darker and smaller defects

3.2.3. Detection system

Theory

Each camera scans the product with a speed of 4000 FPS (Frames/Scans per Second). All cameras scan

the belt vertically, directly or via mirrors. Each scan consists of only one line, but because the cameras are

very fast, the successive scans provide a complete image of everything passing the detection zone.

Every camera signal consists of 2048 pixels in one line, where each pixel will give a value between 0

(black) and 255 (white/colour). Usually this signal will be somewhat curved due to the fact that the camera

is positioned closer to the centre of the belt and further from the sides of the belt. Because of this, less

light is refl ected into the camera from the sides.

To counter this curve effect, the signal must be normalized (reference lines must be taken) regularly (at

least once a day) to achieve a straight empty belt signal line (see Normalization).

Product, defects and transport belt absorb and refl ect more or less of the light from the illumination (HF

lamps/LEDs/lasers), and in different wavelengths (colours). Using different kinds of thresholds, good

product is distinguished from bad product by means of this contrast: the differences in the light that is

refl ected/absorbed. Apart from the thresholds, 2 more parameters can be set to determine the fi nal sorting

result: the defect size (2D), and the defect density or fi ll rate percentage (see sorting parameters).

Loading...

Loading...