Chapter 6: Cleaning Procedure

6/1

Operators & Maintenance Manual GENIUS Compact Version UK 0.1 © BESTnv

BESTnv Industrial Research BV, Marinus van Meelweg 20, 5657 EN, EINDHOVEN, THE NETHERLANDS

General tel. +31 (40) 292 2622 - Service tel. +31 (40) 292 2620 - Fax. +31 (40) 292 2633 - Email: service.BESTnv@bestnv.com

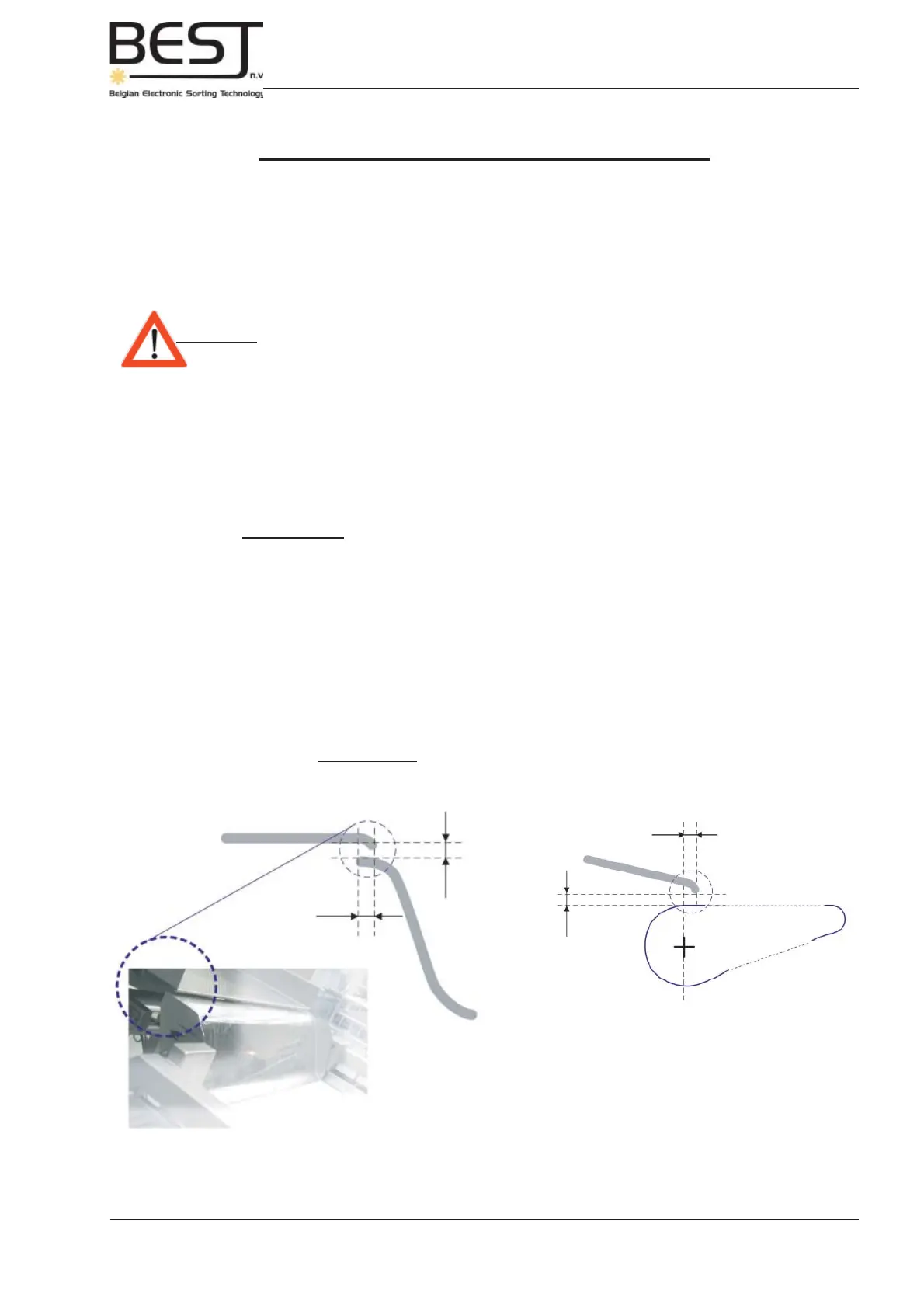

Picture 2.5.11: Relative position of infeed shaker

(sorter with infeed chute) (sorter without infeed chute)

Infeed

chute

Infeed

shaker

A

B

A = 1.0 cm

(0.4”)

B = 1.0 cm (0.4”)

A

B

Infeed

shaker

Transport belt

VI. Cleaning the GENIUS Compact

All points of this Cleaning procedure (if applicable to your machine) should be done at least

once per shift (begin or end) unless explicitly indicated otherwise.

First read this cleaning procedure completely and thoroughly before starting cleaning.

All cleaning and maintenance personnel should be acquainted with this procedure.

Attention: - When using detergents, always make sure they are nontoxic, non corrosive

and non abrasive. If in doubt, please contact BESTnv.

- Always make sure that all doors are closed before cleaning. Dirt, water

and/or water vapour inside the machine could seriously affect the sorting

effi ciency and even damage the machine itself.

6.1. Cleaning Procedure

1. Clean the Infeed Shaker: (after every shift)

- 1. Hose down with water or compressed air. Remove all dust and dirt, but make sure not to damage the

shaker surface. Dirt buildup or scratches in the shaker surface may impede the proper product fl ow.

- 2. If your shaker is equipped with a wire mesh or a wedge wire grid, remove all material stuck in the

meshes, but make sure not to damage the grid.

- 3. Check the alignment of the infeed shaker versus the infeed chute to the sorter unit.

a) Make sure the sides and the bottom of the Infeed shaker do not touch the infeed chute of

the sorter. Check again when the sorter and the shaker are functioning!

Loading...

Loading...