7/15

Chapter 7: Maintenance

Operators & Maintenance Manual GENIUS Compact Version UK 0.1 © BESTnv

BESTnv Industrial Research BV, Marinus van Meelweg 20, 5657 EN, EINDHOVEN, THE NETHERLANDS

General tel. +31 (40) 292 2622 - Service tel. +31 (40) 292 2620 - Fax. +31 (40) 292 2633 - Email: service.BESTnv@bestnv.com

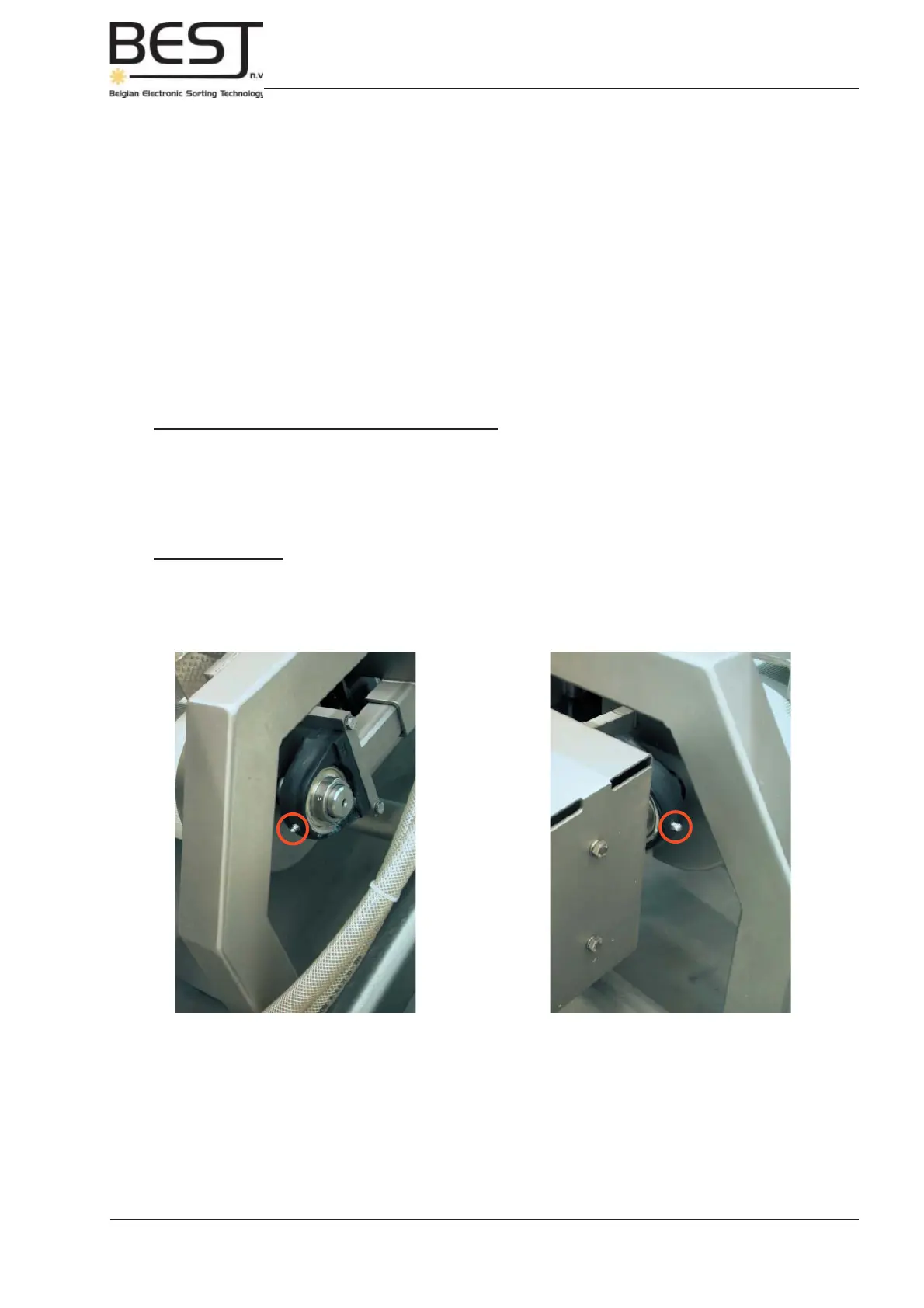

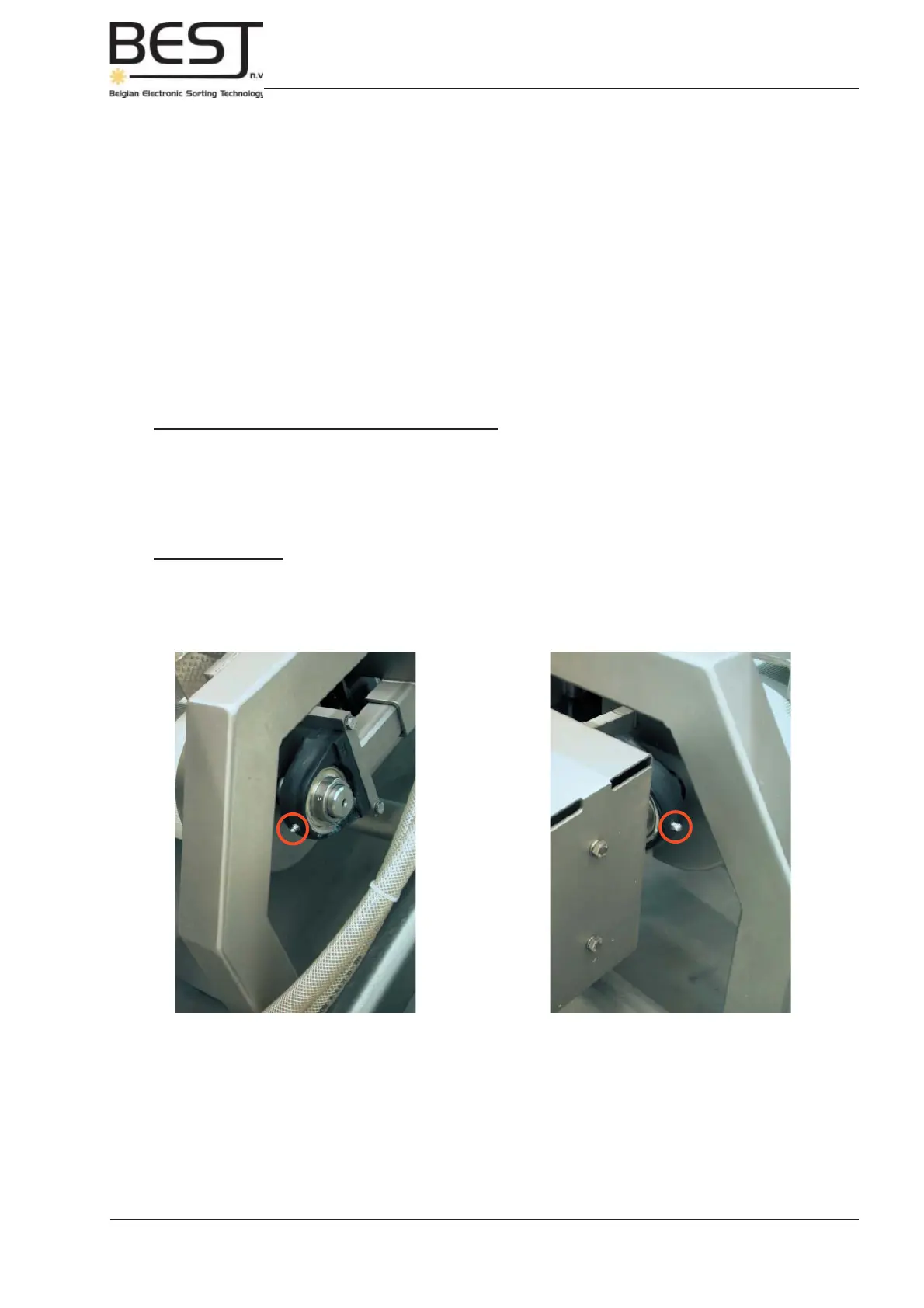

right greasing nipple drive drum left greasing nipple drive drum

7.6. Greasing the bearings

The bearings for all rotating elements, including drive drum, return axles, background drums (laser box

option), etc... must be greased regularly. See following schematic:

- The re-greasable seals must be greased monthly in case of approximately 8 h of continuous use per

day. If the belt is used more extensively it should be greased more often.

- If the belt is installed in aggressive environment and in continuous contact with water, salt, dust, etc.,

or when working under full load it will be necessary to re-grease more frequently.

- If the belt is cleaned by means of special chemical detergents, high pressure water or steam, re-

greasing should take place daily when such cleaning removes the grease from the seals.

Procedure for greasing the re-greasable seals:

1. - Inject grease into the greasing nipples.

2. - Turn on the belt to spread the grease over the ball bearings.

Drive drum system

Greasing nipples can be found at both sides of the drive drum. Regularly add grease into greasing

nipples.

Loading...

Loading...