Chapter 2: Pre-installation Guide:

Unpacking & placing of GENIUS Compact optical sorter

2/8

Operators & Maintenance Manual GENIUS Compact Version UK 0.1 © BESTnv

Pulsarr Industrial Research BV, Marinus van Meelweg 20, 5657 EN, EINDHOVEN, THE NETHERLANDS

General tel. +31 (40) 292 2622 - Service tel. +31 (40) 292 2620 - Fax. +31 (40) 292 2633 - Email: service.pulsarr@bestnv.com

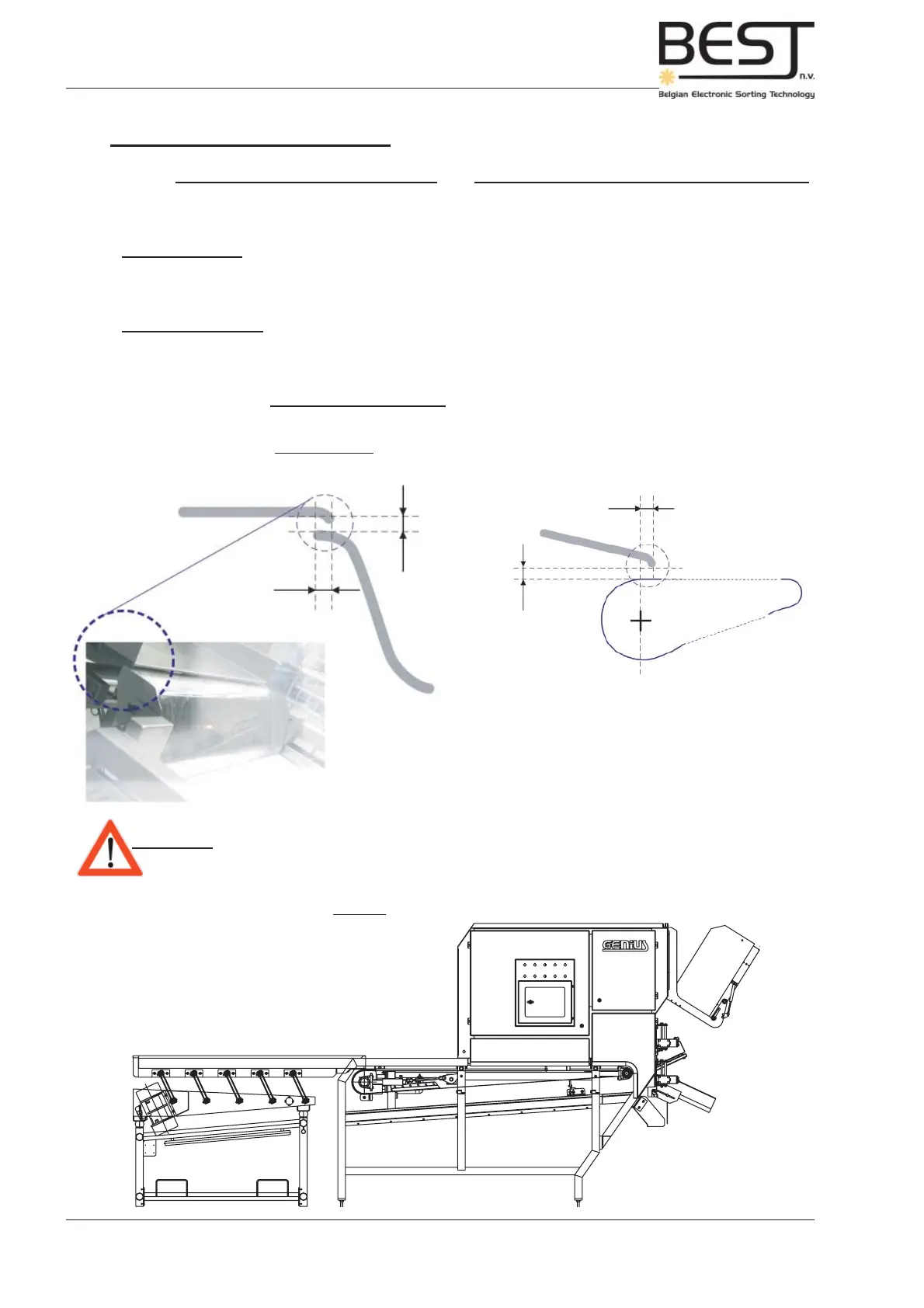

Picture: Placing the shaker unit

Picture 2.5.11: Relative position of infeed shaker

(sorter with infeed chute) (sorter without infeed chute)

Infeed

chute

Infeed

shaker

A

B

A = 1.0 cm

(0.4”)

B = 1.0 cm (0.4”)

A

B

Infeed

shaker

Transport belt

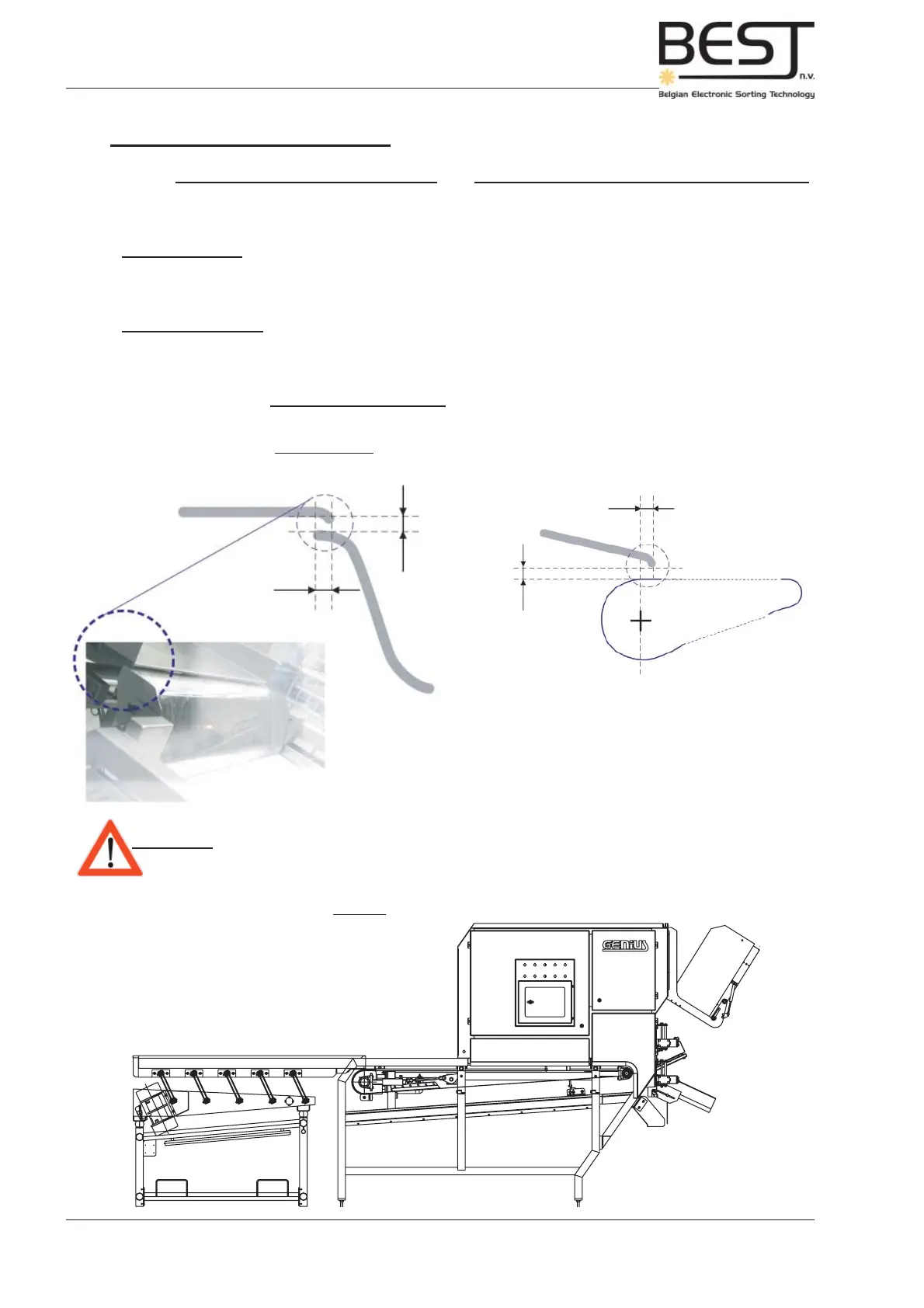

2.4.2. Placing the different units

Once the GENIUS Compact optical sorter unit (see 2.5.2. The GENIUS Compact optical sorter unit)

has been placed in the production line, lift the shaker unit and turn in the adjustable feet (see pictures).

- Move the shaker up against the front of the sorter unit:

With infeed chute: the gap between the infeed shaker nose and the infeed chute of the sorter unit

should be no more than 1.0 cm (0.4”) in height. The nose of the shaker should overlap the beginning

of the infeed chute by approximately 1.0 cm (0.4”).

Without infeed chute: the gap between the infeed shaker nose and the belt drive drum should be no

more than 1.0 cm (0.4”) in height. The nose of the shaker should overlap the highest point of the belt

drive drum by approximately 1.0 cm (0.4”).

(For further details see 2.5.3. The Infeed shaker).

Attention: - Do not fi x the sorter unit or the shaker frame to the ground before the fi nal

position has been determined and approved by BESTnv’s service engineer

during the commissioning.

Loading...

Loading...