6/2

Chapter 6: Cleaning Procedure

Operators & Maintenance Manual GENIUS Compact Version UK 0.1 © BESTnv

BESTnv Industrial Research BV, Marinus van Meelweg 20, 5657 EN, EINDHOVEN, THE NETHERLANDS

General tel. +31 (40) 292 2622 - Service tel. +31 (40) 292 2620 - Fax. +31 (40) 292 2633 - Email: service.BESTnv@bestnv.com

2. Clean the Sorter unit: (after every shift)

- 1. Clean all areas that come into contact with the product from top to bottom (brush lightly and rinse

with cold water).

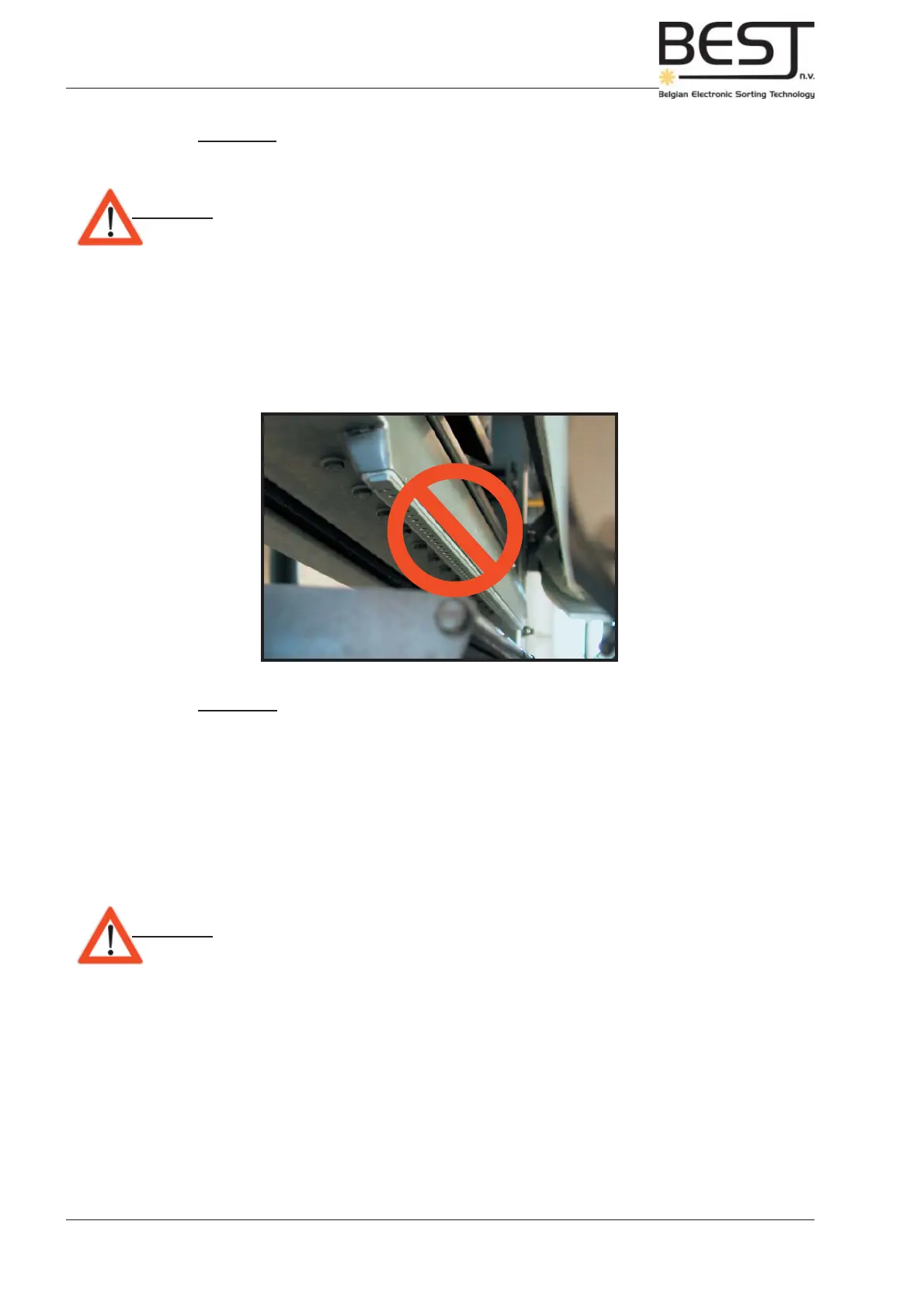

Attention: - Always clean from top to bottom, to prevent dirt from piling up on the lower

sorter parts.

- Make sure all doors and cabinets are closed.

- When hydroblasting, spray from at least 30 cm distance, and avoid spraying

directly on the control panel, the belt edges and the joints of cabinets and

doors.

- Never spray directly into bearings, air gun valves and the edges of the

rotating light tubes.

3. Clean the Sorter Belt: (after every shift)

- 1. Clean the Belt daily with an Alkaline detergent.

- Remove coarse and loose dirt by brushing and rinsing with cold water

- Apply alkaline cleaning solution by spraying, brushing or foaming

- Rinse thoroughly after the prescribed saturation time

- Disinfect and rinse again if necessary

- 3. Once a week an Acid detergent should be used instead of an Alkaline, to prevent lime deposits.

- Always rinse thoroughly afterwards.

- Never use an Acid detergent when the equipment will not be used for more than 24 hours.

Attention: - Never exceed the proscribed concentration of detergent or the saturation

time, for this could damage the belt.

- The environmental temperature or the temperature of water or detergents

should never exceed 50°C, for this may cause protein adhesion, and thus

reduce the sorting effi ciency.

- When hydroblasting, spray from at least 30 cm distance, and avoid spraying

the Belt edges.

- Be very careful with sharp objects, such as steel sponges or putty knives,

these can easily damage the Belt.

Loading...

Loading...