Chapter 6: Cleaning Procedure

6/3

Operators & Maintenance Manual GENIUS Compact Version UK 0.1 © BESTnv

BESTnv Industrial Research BV, Marinus van Meelweg 20, 5657 EN, EINDHOVEN, THE NETHERLANDS

General tel. +31 (40) 292 2622 - Service tel. +31 (40) 292 2620 - Fax. +31 (40) 292 2633 - Email: service.BESTnv@bestnv.com

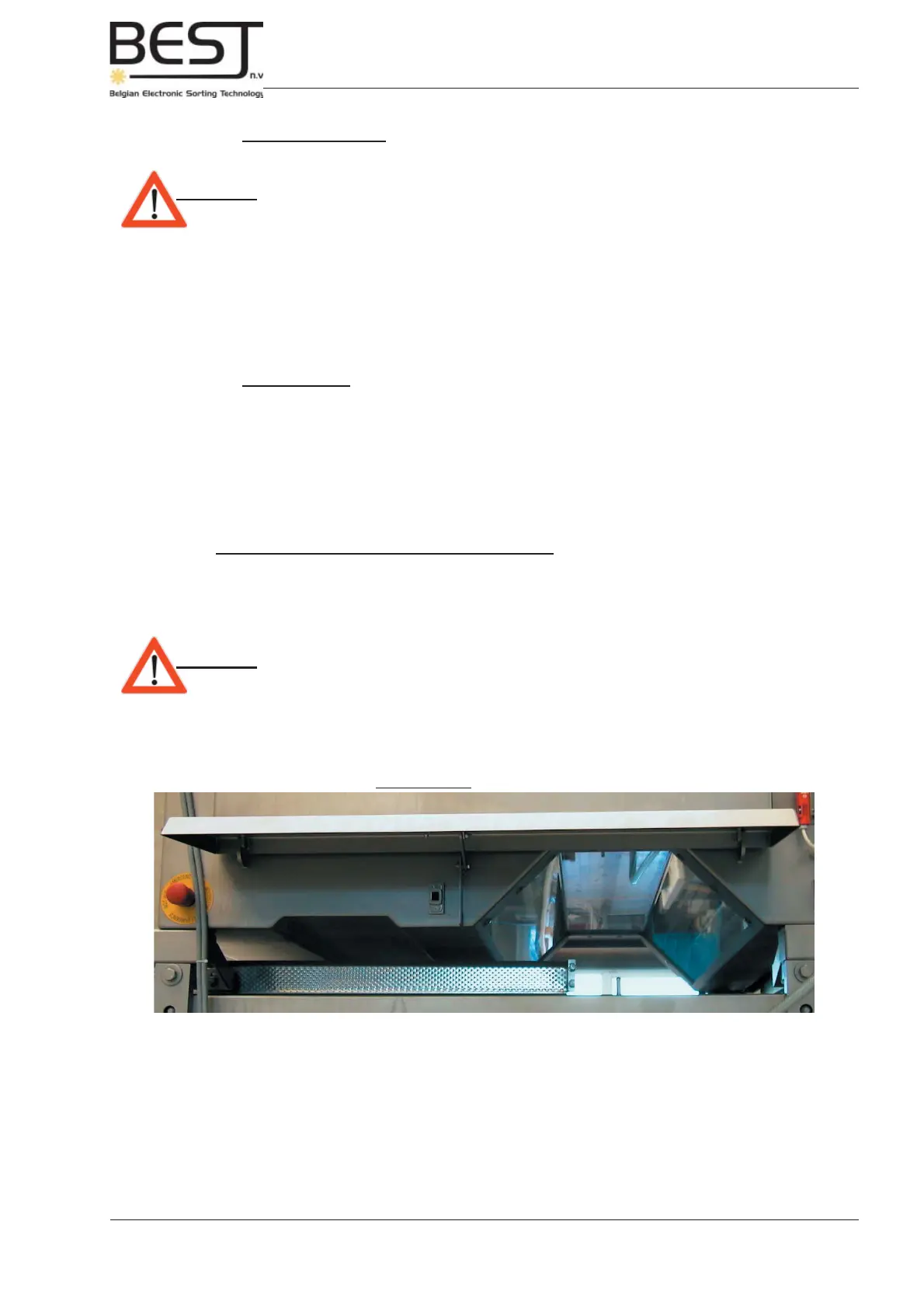

Picture 6.1.1.: Detection zone 1

Illumination Windows

detection zone 1

4. Clean the Background Drums (if present): (every shift)

- 1. Use a clean soft cloth and alcohol or another non-corrosive and non-abrasive detergent.

Attention: - Do not scratch or otherwise damage the drum surface.

- To clean the background drums BESTnv advises the 3M Marine Fibreglass

Cleaner and Wax. To remove small scratches BESTnv advises the 3M Marine

Fibreglass Restorer and Wax.

- A damaged or dirty background drum could cause false detections and

signifi cantly decrease the effi ciency of the sorter.

5. Clean the Return system (if present): (every shift)

(this includes all accept/reject shakers/belts that are part of the GENIUS Compact installation)

- 1. Scrape loose and remove dust and dirt if necessary.

- 2. Spray from top to bottom with clean water (with non-corrosive detergent if necessary)

- 3. Check positioning of return system parts to ensure optimum product fl ow.

6. Clean Windows of Illumination unit detection zone 1: (every shift)

- 1. Lift up side cover plate (see picture below).

- 2. Spray the windows of the illumination units with clean cold water without detergents.

Dry them with a clean cloth to avoid scale (only on the outside of the machine, over the belt).

Attention: - Do not scratch or otherwise damage any of the illumination windows.

- Avoid scale, water drops and/or any spots that could infl uence the sorting

effi ciency.

Loading...

Loading...