7/11

Chapter 7: Maintenance

Operators & Maintenance Manual GENIUS Compact Version UK 0.1 © BESTnv

BESTnv Industrial Research BV, Marinus van Meelweg 20, 5657 EN, EINDHOVEN, THE NETHERLANDS

General tel. +31 (40) 292 2622 - Service tel. +31 (40) 292 2620 - Fax. +31 (40) 292 2633 - Email: service.BESTnv@bestnv.com

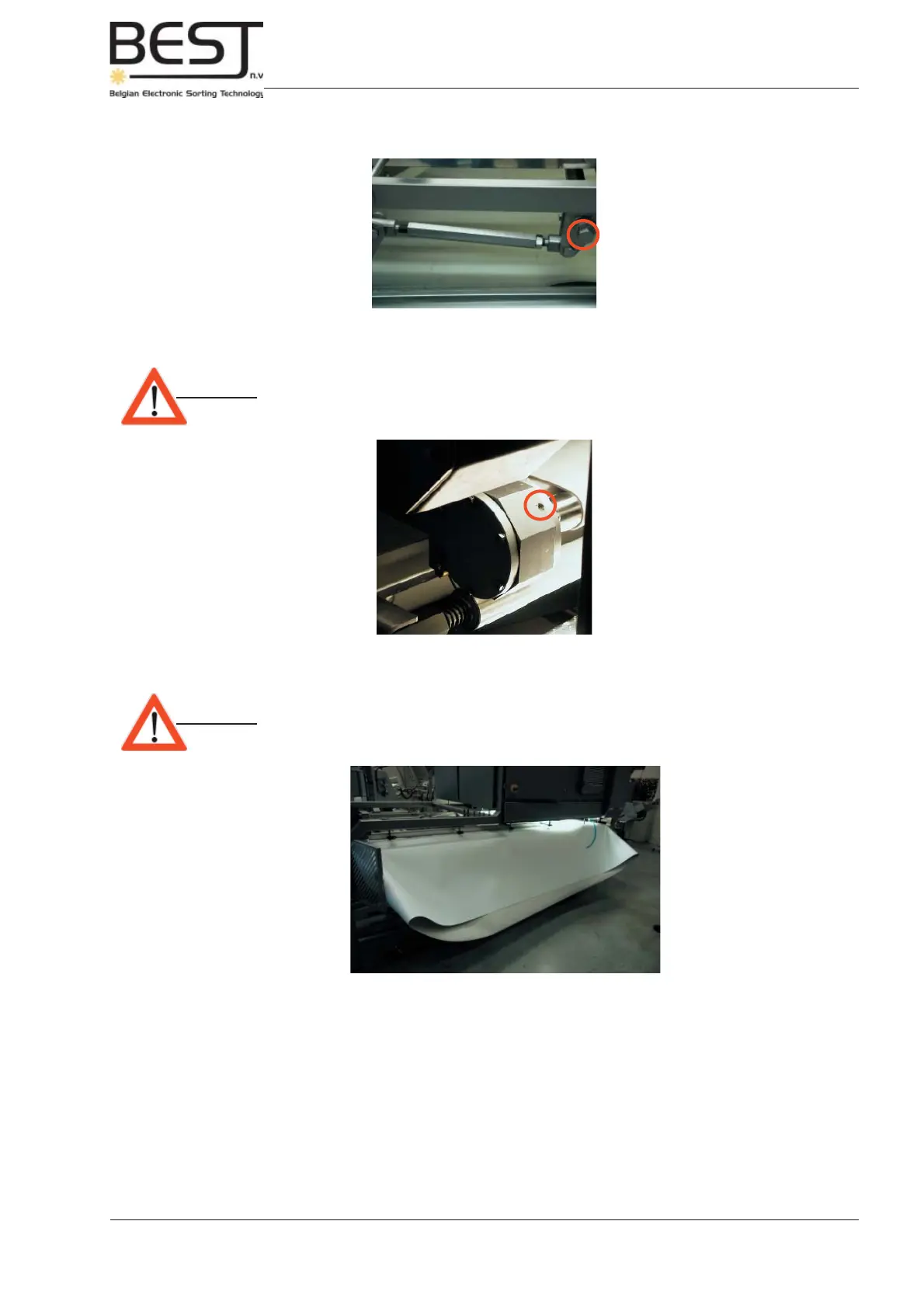

4. Release belt tension mechanism by turning the big hexagon screw to the left.

5. Remove grease nipple on right bearings block of return axle. This grease nipple would make replacing

the belt much more diffi cult, and could damage the new belt.

Attention: - Make sure to always place the greasing nipple back after replacing the belt,

without it greasing of the bearings is impossible.

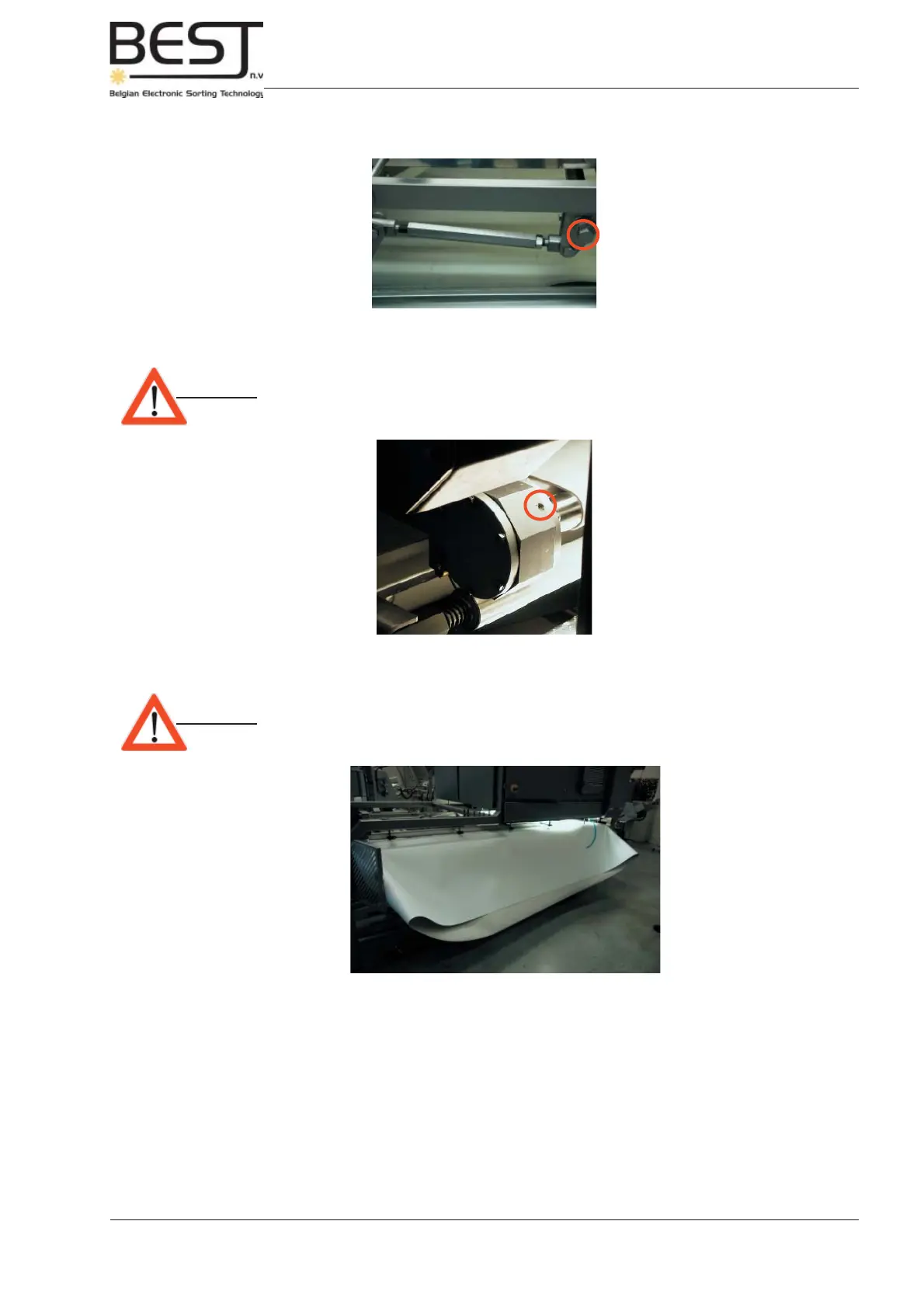

6. Remove old belt and replace it with a new belt. Place the new belt approximately in the middle.

Attention! - While the rest of the procedure can easily be done by 2, placing the new belt

is best done by 3 persons to avoid damaging the new belt.

7. Close wedges and tightly screw down the bolts.

8. Insert greasing nipple.

9. Perform procedure: Tensing and Tracking of Detection Belt (see next pages)

10. Place back the belt drive drum safety plate (see point 2) and screw the bolt back in to fi x the bearing

block supports (see point 1).

Loading...

Loading...