Chery Automobile Co., Ltd.

51 - WIRE HARNESS

51–9

51

Electrical Repair

Wire Harness Repair

1. Peel off 0.5 inch insulating layer from the lead to be repaired and the substitute lead.

2. Connect the original lead to the substitute lead with the heat shrink tube and compress the metal core of

heat shrink tube with a tool, so that the original lead and the substitute lead can be connected firmly.

3. Heat the heat shrink tube to shrink the outer rubber layer and ensure that the sealing of repaired area is in

good condition.

4. Wrap the repaired lead with insulating tape.

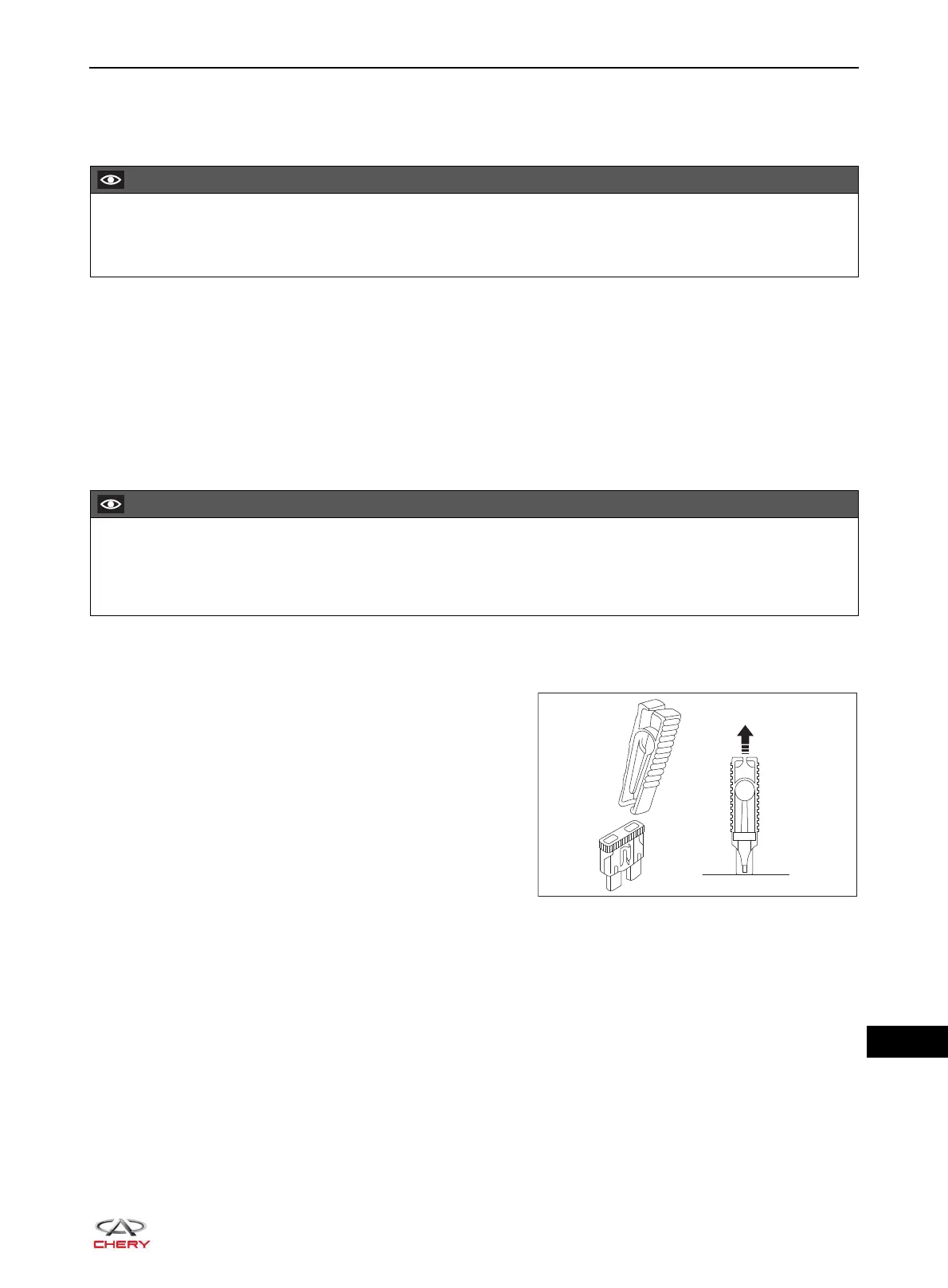

Fuse Replacement

1. Turn off all the electrical equipment and ignition switch before servicing.

2. Remove the blown fuse with a fuse puller.

3. Replace the fuse with a new one which has the same

specification.

Measure the length of lead to be repaired and select a proper substitute lead before servicing.

If there are several leads to be repaired, please stagger the repaired parts.

Energizing test should be performed after replacing the fuse. If the fuse is blown again, check the

corresponding circuit for short. If any electrical equipment or additional device which exceeds the rated

current is installed, replace it with the fuse with higher amperes.

Loading...

Loading...