User's Manual

351

Appendix 5 Particulate and Gaseous

Contamination Specifications

Appendix 5.1 Particulate Contamination Specifications

The following table defines the limitations of the particulate contamination in the operating

environment of the device. If the level of particulate contamination exceeds the specified limitations

and result in device damage or failure, you need to rectify the environmental conditions.

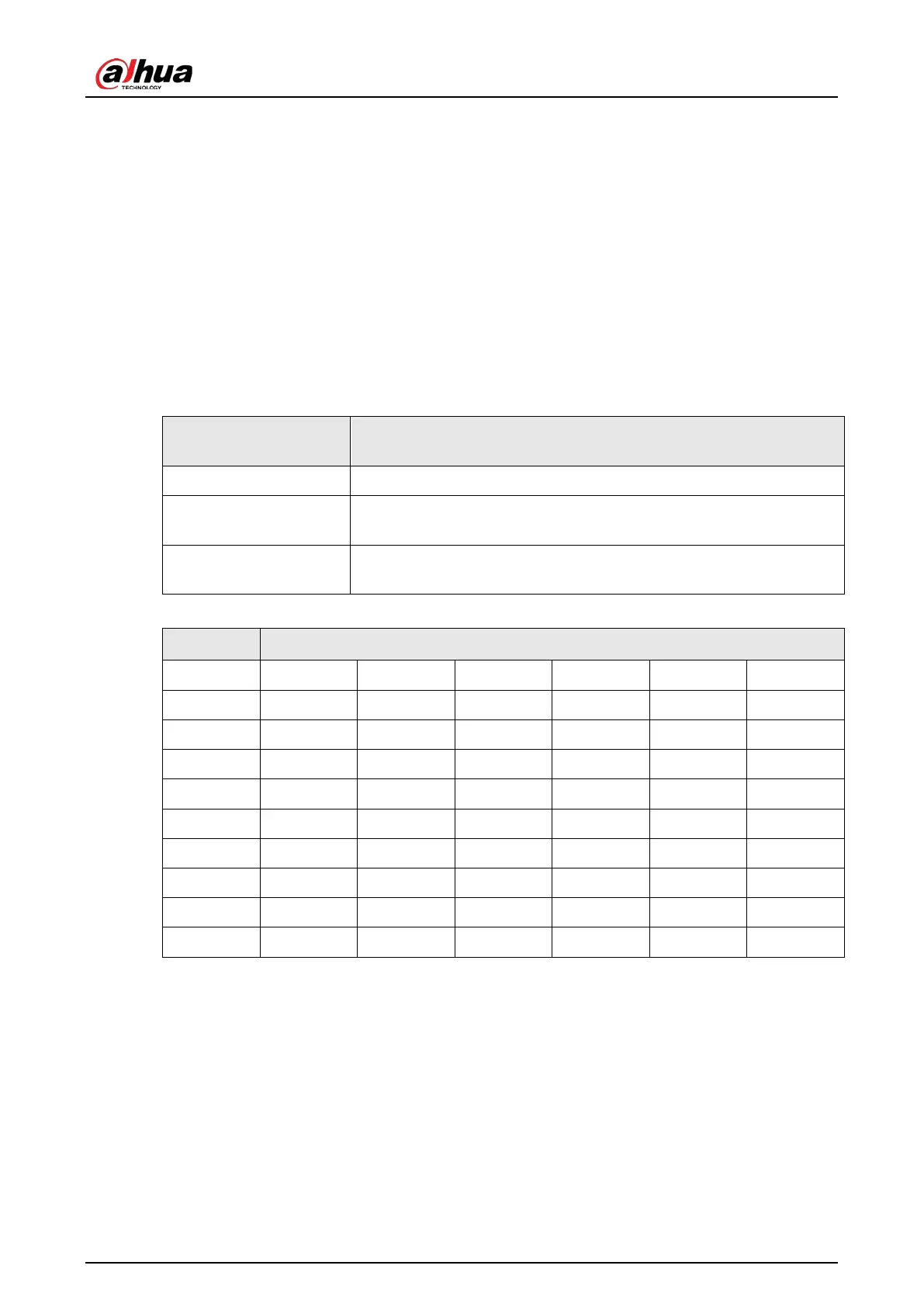

Appendix Table 5-1 Particulate contamination specifications

Particulate

contamination

Air filtration Class 8 as defined by ISO 14644-1.

Conductive dust

Air must be free of conductive dust, zinc whiskers, or other

conductive particles.

Corrosive dust

Air must be free of corrosive dust. Residual dust present in the air

must have a deliquescent point less than 60% relative humidity.

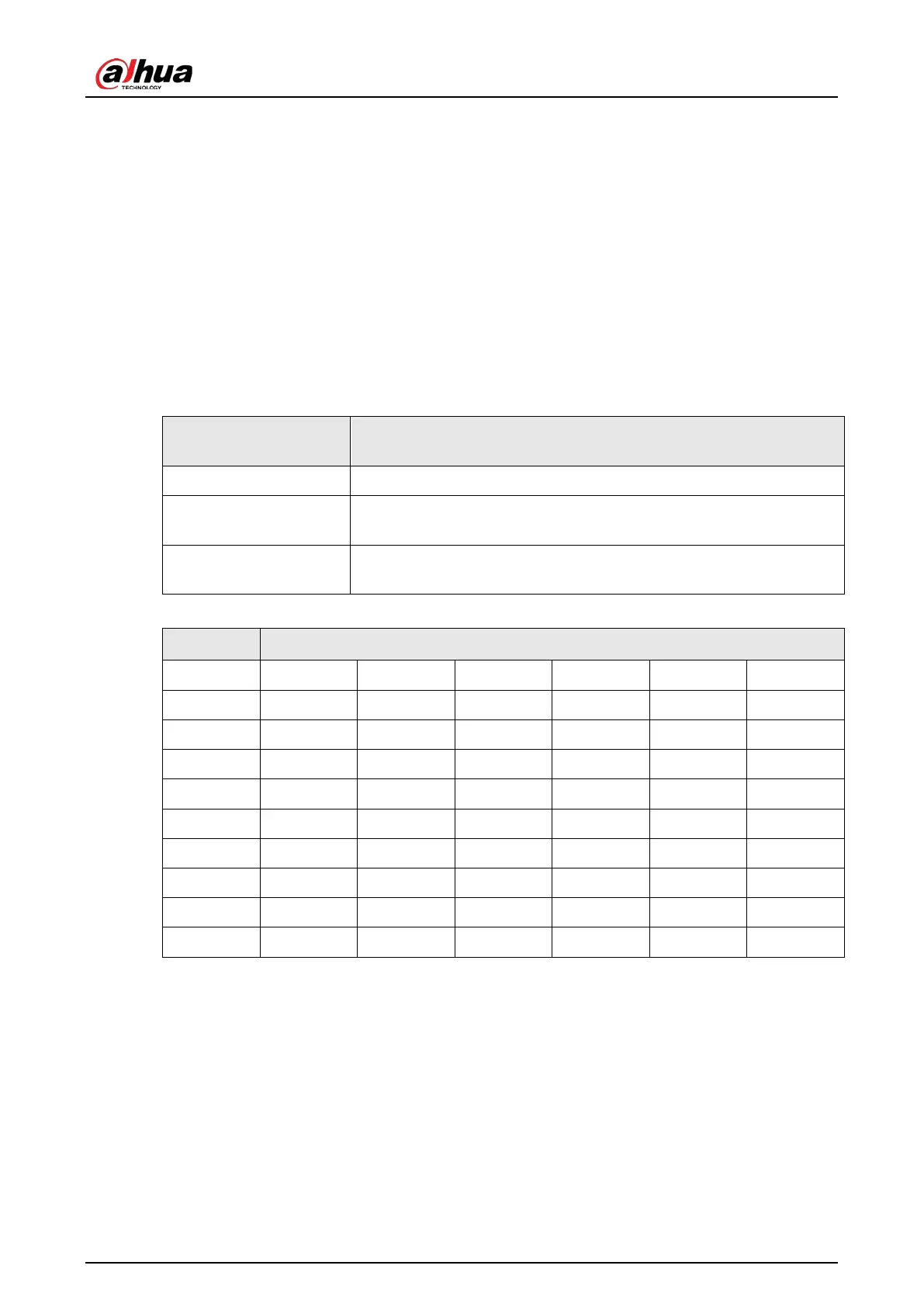

Appendix Table 5-2 ISO 14644-1 cleanroom classification

— ≥ 0.1 μm ≥ 0.2 μm ≥ 0.3 μm ≥ 0.5 μm ≥ 1 μm ≥ 5 μm

Class 1 10 2 — — — —

Class 2 100 24 10 4 — —

Class 3 1000 237 102 35 8 –7

Class 4 10000 2370 1020 352 83 —

Class 5 100000 23700 10200 3520 832 29

Class 6 1000000 237000 102000 35200 8320 293

Class 7 — — — 352000 83200 2930

Class 8 — — — 3520000 832000 29300

Class 9 — — — — 8320000 293000

Appendix 5.2 Gaseous Contamination Specifications

Usually indoor and outdoor atmospheric environments contain a small amount of common

corrosive gas pollutants. When these mixed or single corrosive gas pollutants react with other

environmental factors such as temperature or relative humidity in the long term, the device might

suffer from a risk of corrosion and failure. The following table defines the limitations of the gaseous

contamination in the operating environment of the device.

Loading...

Loading...