3

Layout, function of machine and accessories

3.22

Training manual • Basic training • Status 03.14

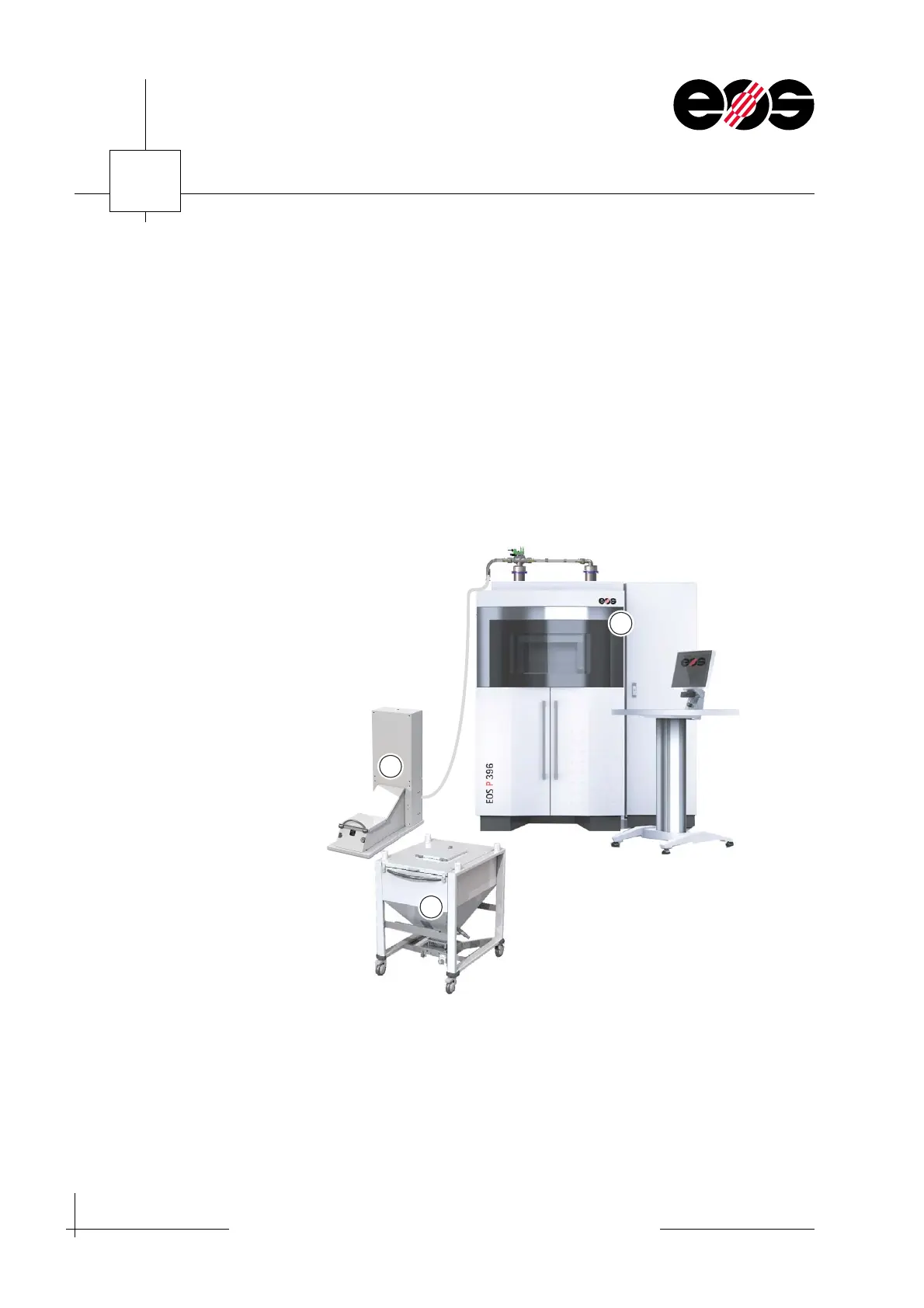

EOS P 396

During the mixing and qualification process new powder is transported to the MQS

from a new powder bin and recycled powder is transported from a multibox.

After the stirring time has elapsed, a sample can be taken from the powder mixture

and checked using suitable methods, e.g. MVR measurement (Melt Volume Rate),

outside the MQS. Via the controller for the MQS it is possible subsequently correct

the mixture ratio based on the measured results, without the need to discharge the

power mixture.

The prepared, refreshed powder is transferred to a multibox (mobile container). For

this purpose a multibox is pushed under the mixing bin and coupled. In the base of

the mixing bin there is a valve for discharging the powder. The level in the multibox

is monitored via a powder sensor in the MQS. The discharge of the powder into the

multibox is controlled via the controller for the MQS.

The multibox with the refreshed powder is pushed to the docking station on the

machine and coupled.

The docking station fills - depending on the filling mode selected - the powder

supply/dosing bin in the machine in the automatic or manual mode. After the end of

A Machine

B Docking station

C Multibox

Loading...

Loading...