Laser sintering process

2.3

Training manual • Basic training • Status 03.14

EOS P 396

2

Factors that affect the laser sintering process

The laser sintering process is affected by the following factors:

➢ Building temperature

➢ Exposure

➢ Process-related effects

➢ Ambient conditions.

To ensure the sintered part meets the quality requirements, these factors must be

taken into account on setting the machine parameters, material parameters as well

as on the selection of the exposure type.

Building temperature

A prerequisite for a trouble-free laser sintering process is the optimum building

temperature. The recommended building temperature is listed in the parameter sheet

for the machine and is dependent on the machine type and the plastic powder used.

At an excessively low building temperature, the outer areas of a layer roll upward.

This behaviour is called curling.

The building temperature must be increased in steps until curling no longer occurs.

Building temperature = process chamber temperature

1 Straight test corner with optimum

building temperature

2 Bed of powder

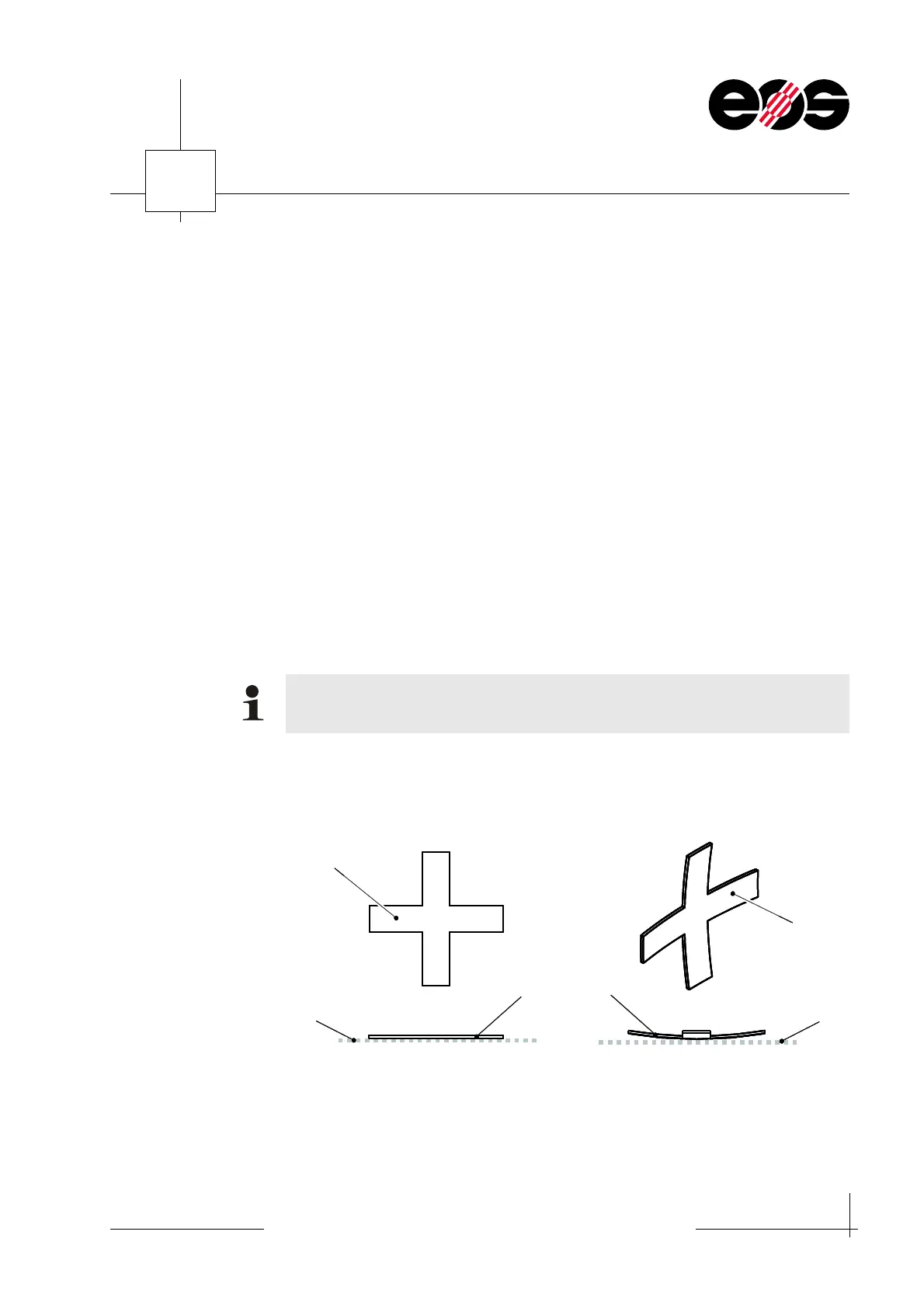

3 Curled test corner with building

temperature that is too low

Loading...

Loading...