2

Laser sintering process

2.10

Training manual • Basic training • Status 03.14

EOS P 396

Distortion

Distortion occurs in the case of large thermal differences during the building process

or during cooling after the end of the building process and results in warped parts.

The distortion is equally dependent on the part geometry and the material used.

During the process the following types of distortion can occur:

➢ Distortion during the building phase

Due to excessively quick cooling of the individual layers in the process chamber

there can be fluctuations in the application of the powder. If, e. g., due to

deformation of the part too little plastic powder is applied at the outer edges, the

part lacks material in this area.

➢ Distortion during the cooling phase

Failure to comply with the recommended cooling time, removing the

exchangeable frame too soon or premature opening of the removal chamber door

will result in the overall job cooling down too quickly. For physical reasons, the

part cools down unevenly from bottom to top and from the outside inwards,

which can result in the distortion of the part in the layers at the bottom.

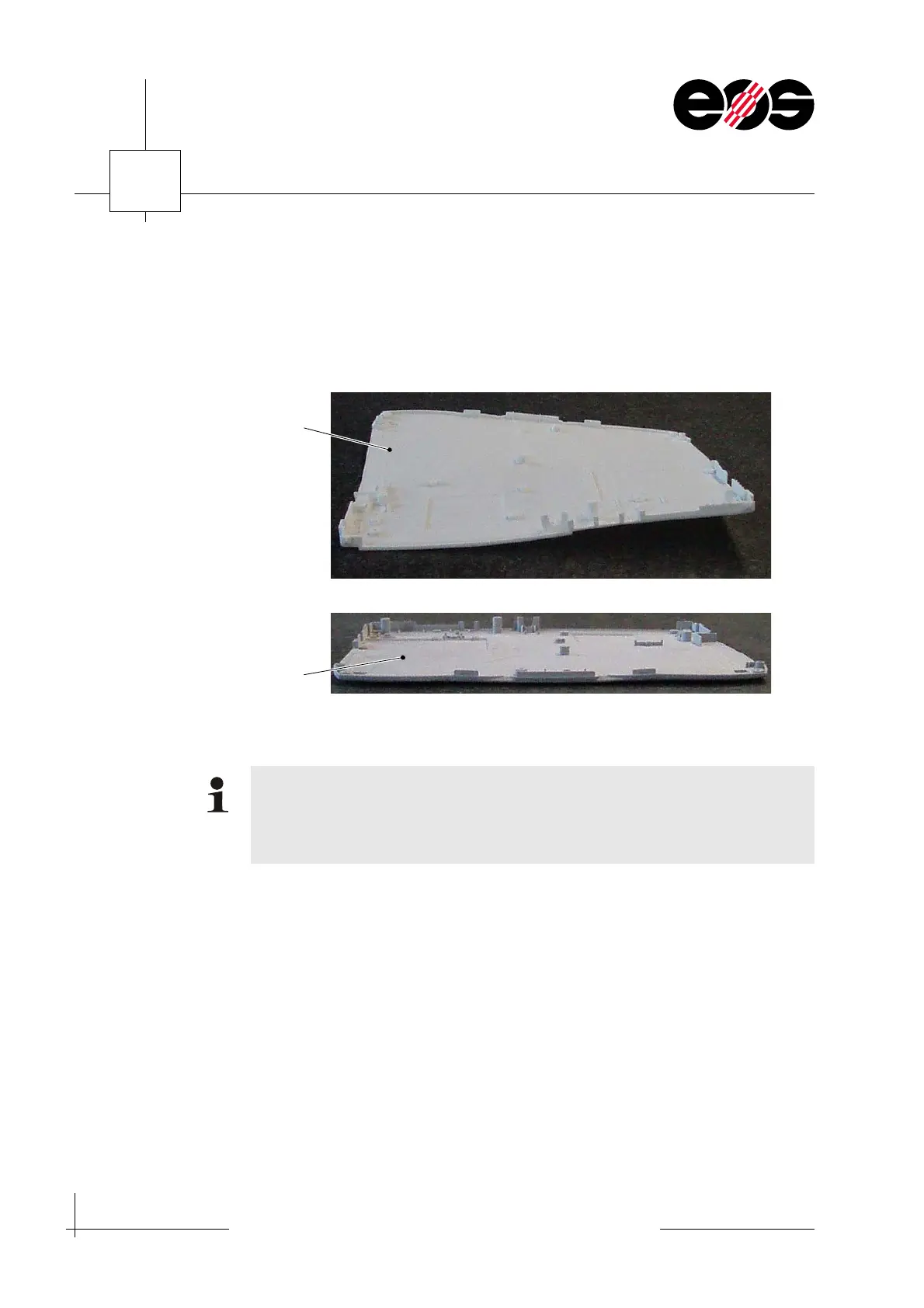

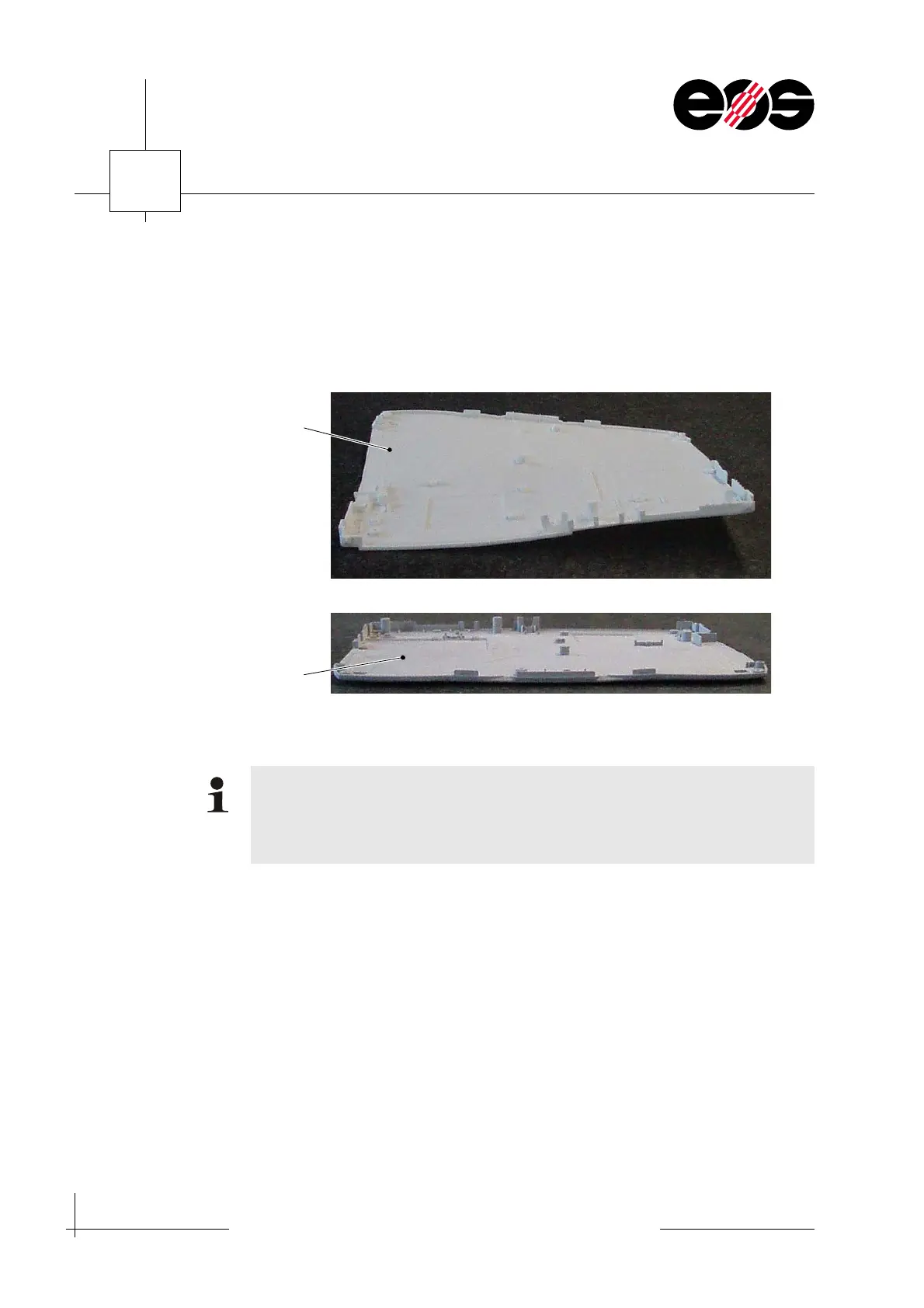

1 Laptop housing made of PA 2200 2 Laptop housing made of Alumide®

The distortion behaviour can be positively influenced by the optimal setting of

the process chamber temperature and removal chamber temperature.

For settings for the process chamber temperature and the removal chamber

temperature, see parameter sheet.

Loading...

Loading...