Basic information on materials

4.5

Training manual • Basic training • Status 03.14

EOS P 396

4

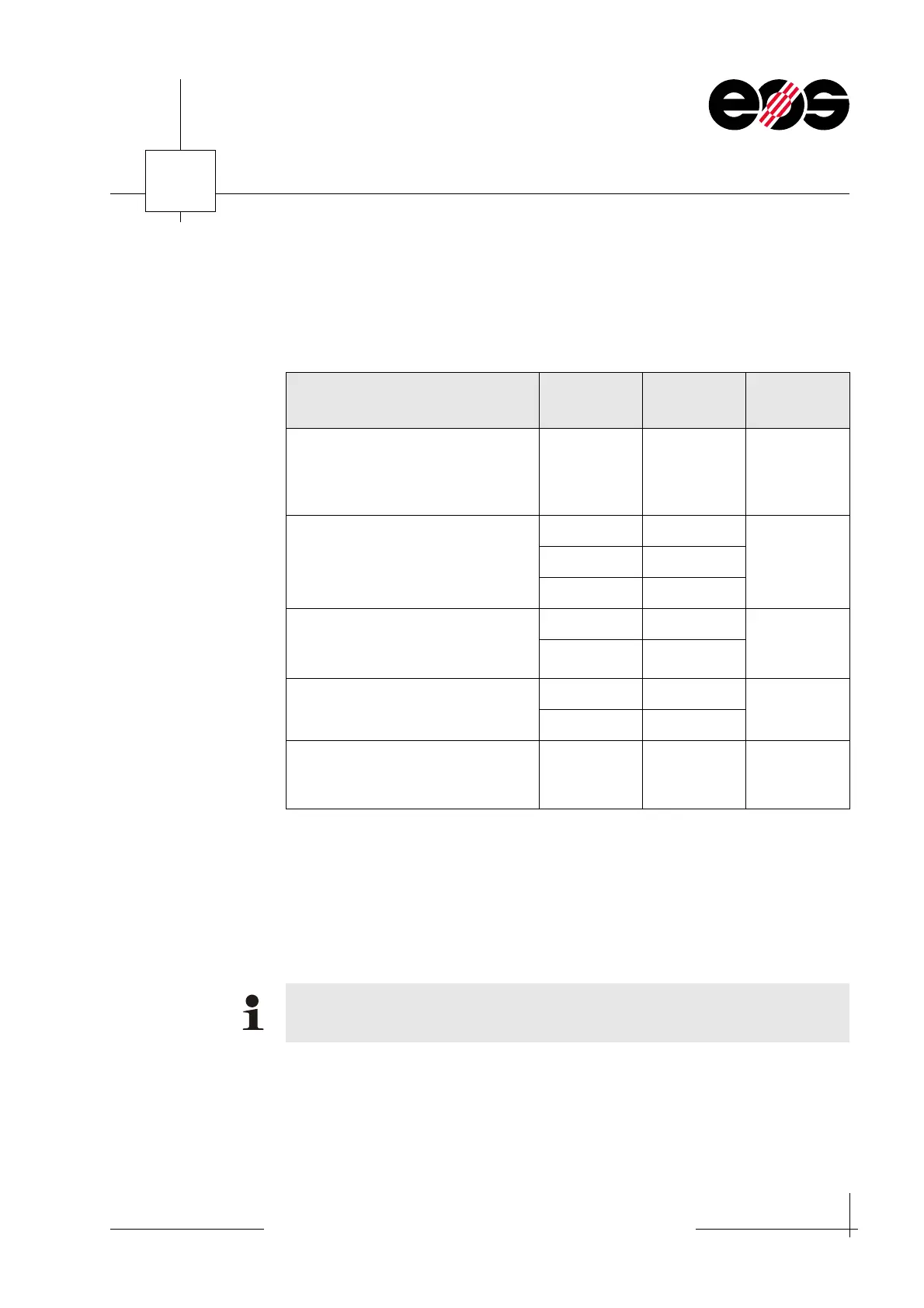

Storage of the powder

For consistent quality of the parts and a trouble-free building process, EOS

recommends the following storage conditions for plastic powder.

1)

From a storage time of 2 years from the test date on the material certificate a loss of quality due to

ageing is possible.

2)

On opening the sacks, temperature and atmospheric humidity should correspond to the installation

conditions for the machine in the operating state.

3)

In the case of open bins the powder must be protected against soiling.

4)

The storage duration is necessary for the electrostatic charging of the powder produced by mixing to

dissipate.

Temperature

[°C]

Atmospheric

humidity [%]

Storage

duration

New powder, used powder,

sieved used powder (recycled powder),

refreshed powder

-> In closed bins

5 - 35 20 - 70

2 years

1)

New powder

-> Prior to opening the sacks

15 - 20 50 - 80

Min. 24 h

2)

> 20 - 25 40 - 60

> 25 - 30 30 - 45

New powder, used powder,

recycled powder, refreshed powder

-> In bins with air change

3)

20 - 25 40 - 60 Max. 6 months

25 - 30 30 - 45

Powder after sieving/mixing

In bins with air change

3)

20 - 25 40 - 60

Min. 24 h

4)

25 - 30 30 - 45

Refreshed powder (conditioned)

-> In multibox (closed bins)

5 - 35 20 - 80

non-

condensing

Min. 24 h

4)

For long-term storage the plastic powder should be stored in closed bins to avoid

soiling.

Loading...

Loading...