4

Basic information on materials

4.2

Training manual • Basic training • Status 03.14

EOS P 396

parts. It occurs primarily during the building process with polyamide powder. For

this reason used polyamide powder must be mixed with new powder (refreshed).

In the case of filled plastic powder, this ageing is further accelerated by the filler

material such that the refresh factors are correspondingly higher, or refreshing

may not be possible at all.

If the powder ageing process is excessively advanced, this effect can be seen in

sink marks (surface imperfections) on the parts.

Polystyrene powder can be considered uncritical in relation to ageing.

The damage to the plastic powder in the exchangeable frame varies depending

on the position in the exchangeable frame:

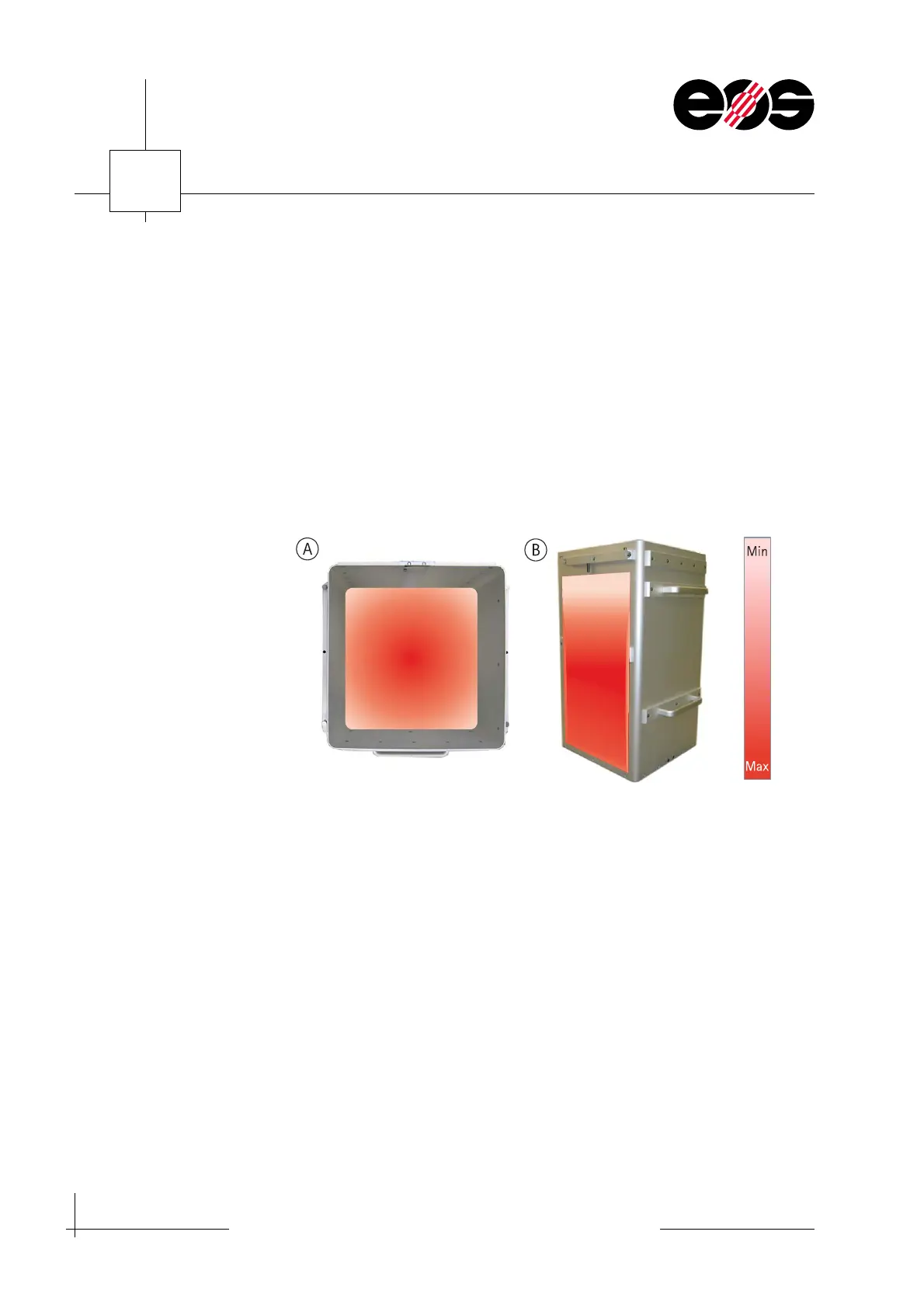

➢ Powder in the middle of the building area is damaged more than powder at the

edge of the building area.

The temperature in the middle of the building area is higher than at the edges,

as a consequence the powder is damaged more in the middle.

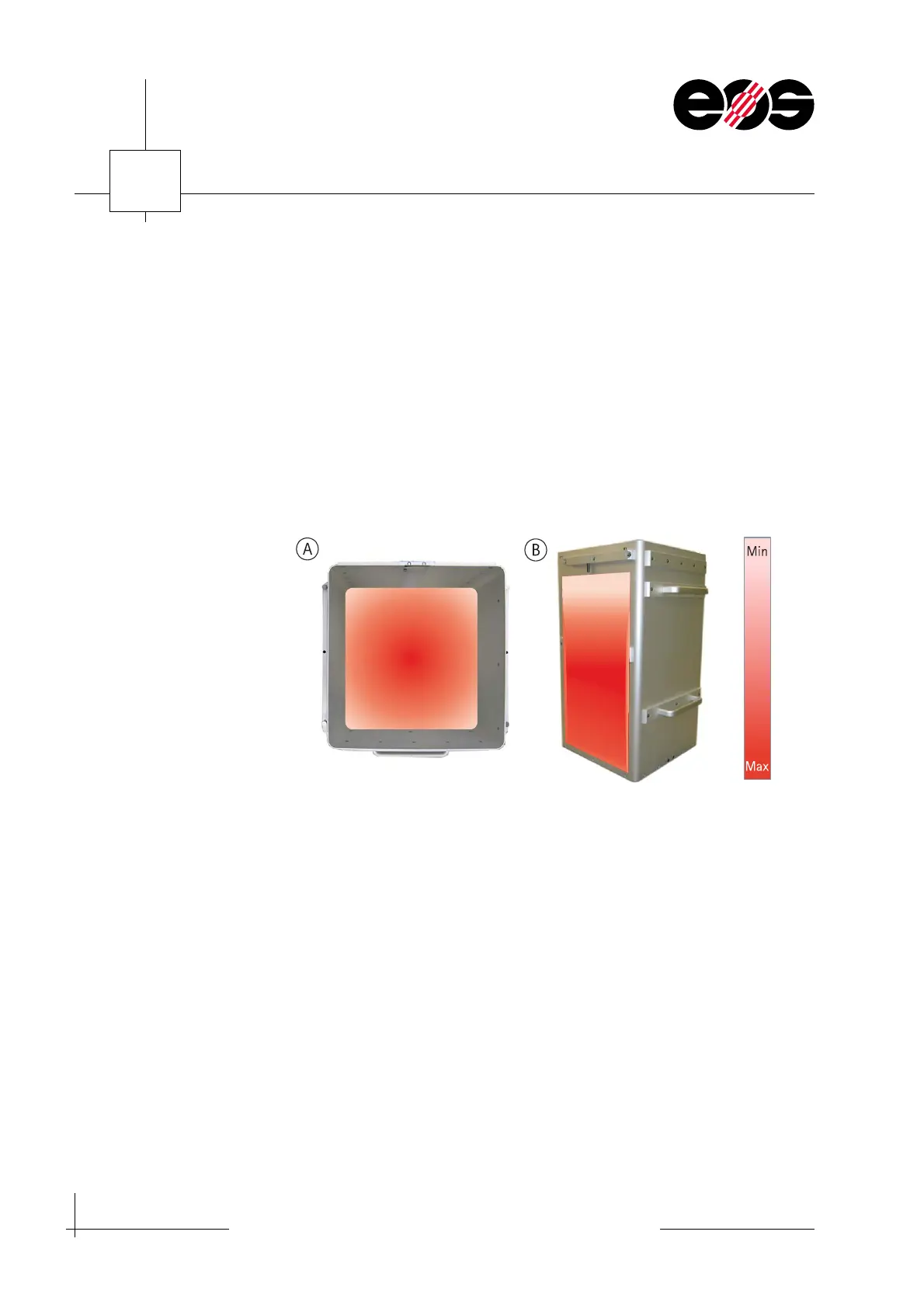

➢ Powder in the middle of the exchangeable frame is damaged more than at the

top and bottom.

The longer the powder is in the exchangeable frame, the more it is damaged by

the high temperature. The thermal load on the powder is greatest in the centre

of the exchangeable frame, as the powder there is subject to high temperatures

for the longest.

A Damage to the powder in

X/Y direction

B Damage to the powder in Z direction

Loading...

Loading...