CHAPTER 5

PAGE 21

PAGE DATE: 21. March 2014

MAINTENANCE MANUAL EXTRA 300LT

O 10 Check rudder cable system including sleeves, fairleads,

pulleys and cable retracting springs per FAA-AC 43.13-1A.

O O 11 Check PTFE tube within the S-guidance at the rear seat

rudder pedal for general condition.

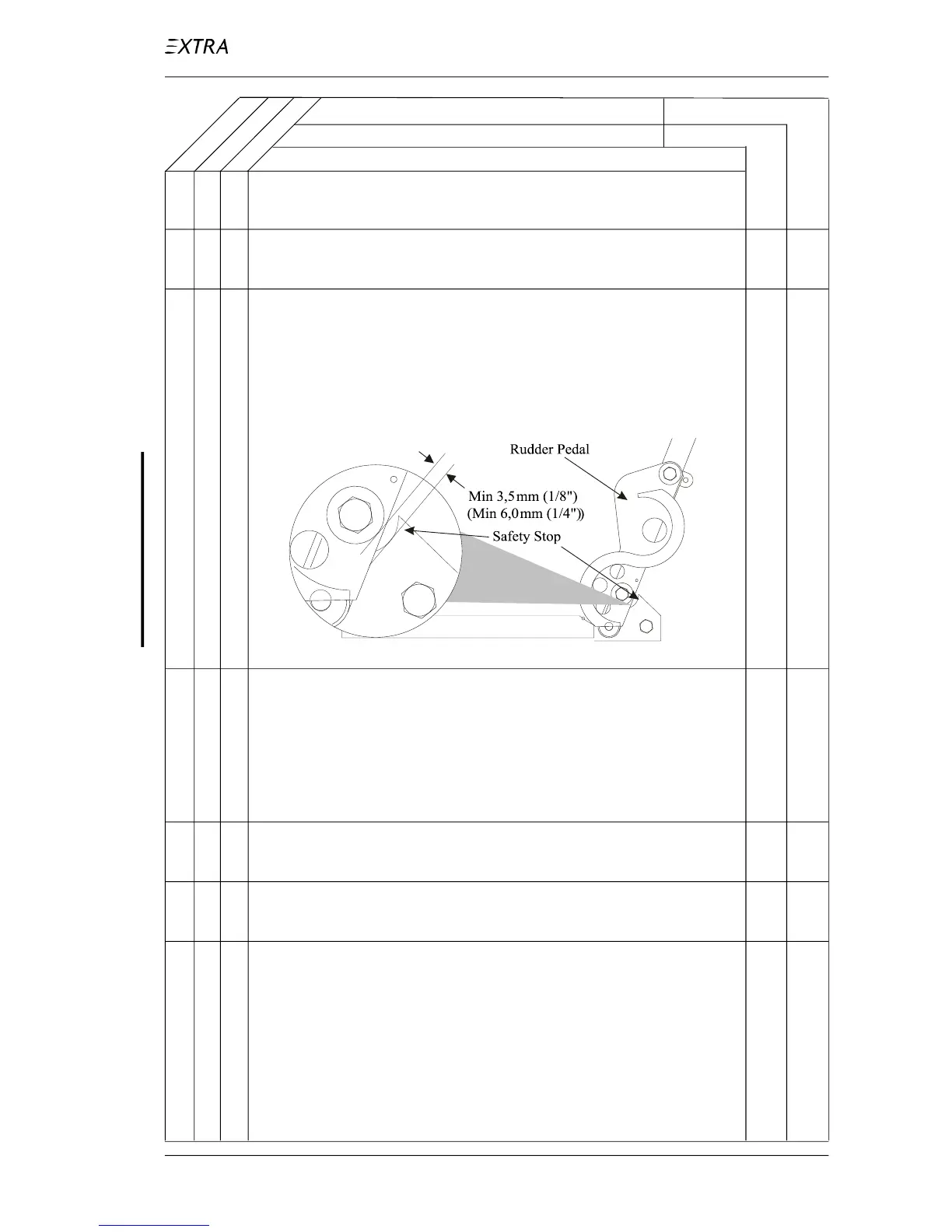

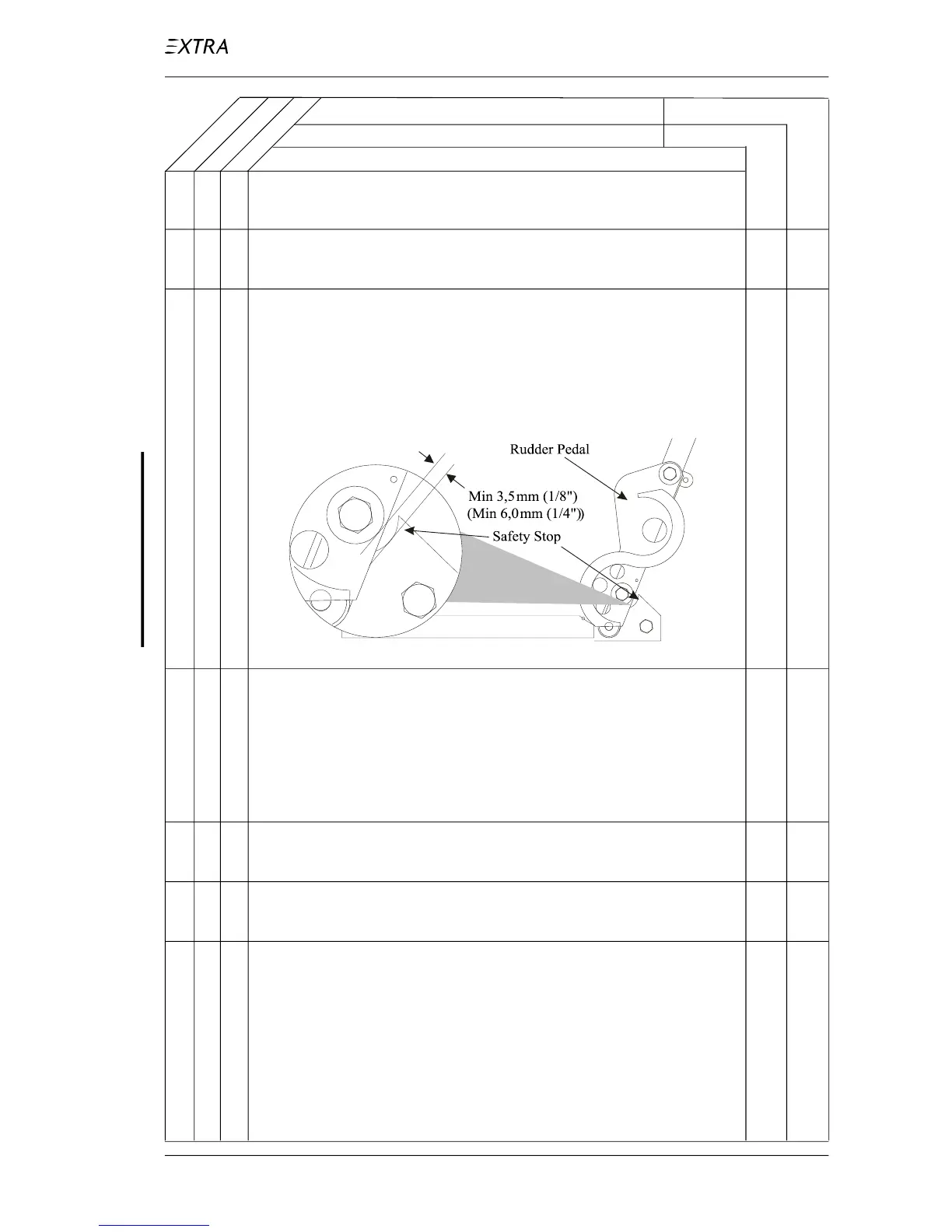

O 12 Check for minimum 3.5 mm (1/8") clearance of rudder

pedal versus safety stop when fully deflected for rudder

cables having 50 h flight time minimum. On newly installed

rudder cables the minimum spacing is 6 mm (1/4"). This

check is to be performed with zero loading on the rudder

pedals.

O 13 Rough check of safety stop clearance. With a force of

approx. 90 kg (200 lbs) acting on the fully deflected rudder

pedal the safety stop shall not be reached. If the stop is

reached the control system indicates too much flexibility

which needs to be traced. In this case contact EXTRA

Flugzeugproduktions- und Vertriebs- GmbH for advice.

O O 14 Inspect all flight control surface ventilation holes for ob-

struction.

O 15 Inspect elevator balance weights for looseness, clearance,

condition and interference with the composite structure.

O 16 Visual inspect push/pull control rods for corrosion, cracks,

or other visible damage, especially at their end fittings. In

case of suspected cracks, remove push/pull control rod,

strip the paint in the suspected area and carry out a detailed

inspection using a magnifying glass (x10). Replace the

related control rod in case a crack is found otherwise

reapply surface treatment and reinstall push/pull control

rod.

Inspector:

Mechanic:

Date:

Serial No.:

Inspections

as specif

i

ed

eac

h

100 hours

SCHEDULED MAINTENANCE CHECKS

Maintenance Checks Schedule

eac

h

50 hours

Loading...

Loading...