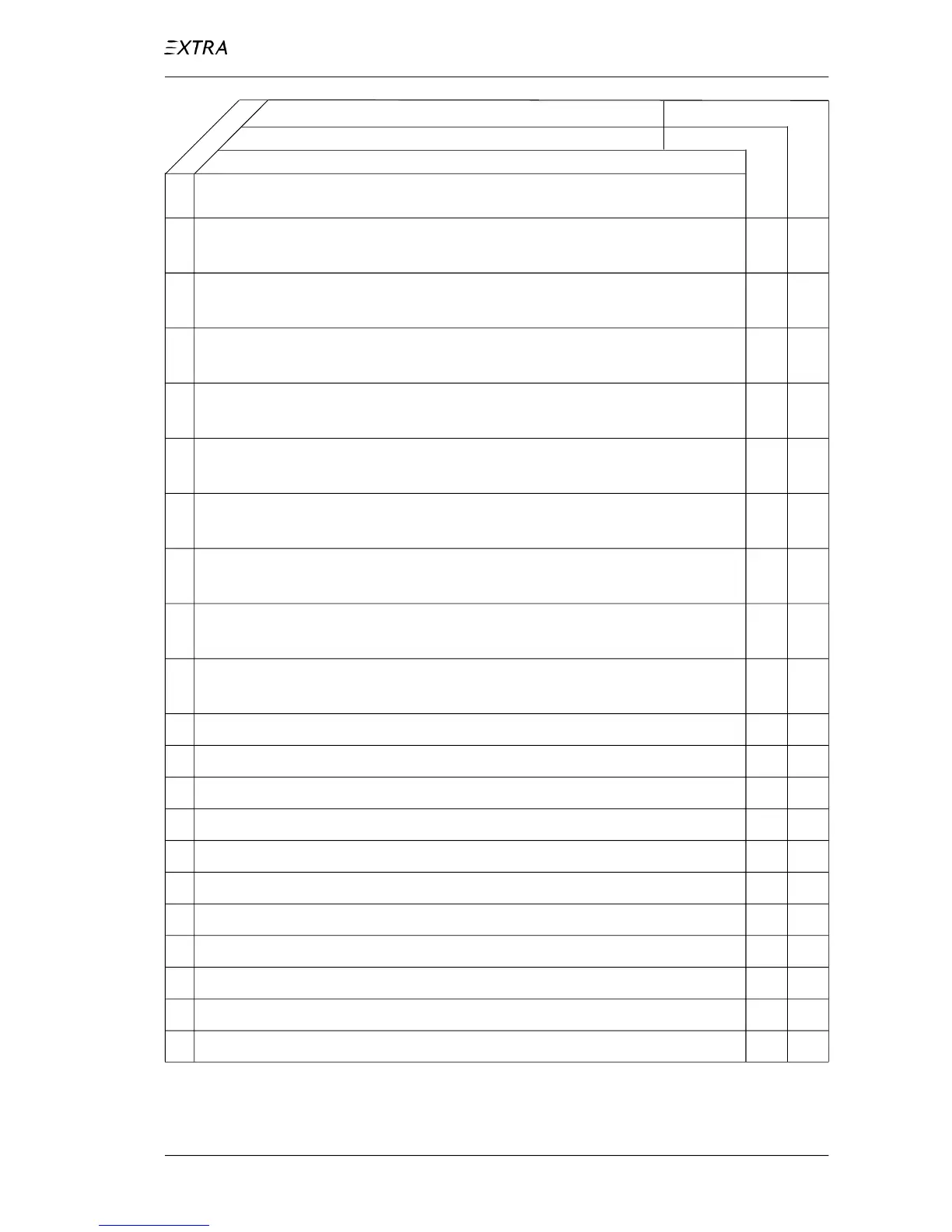

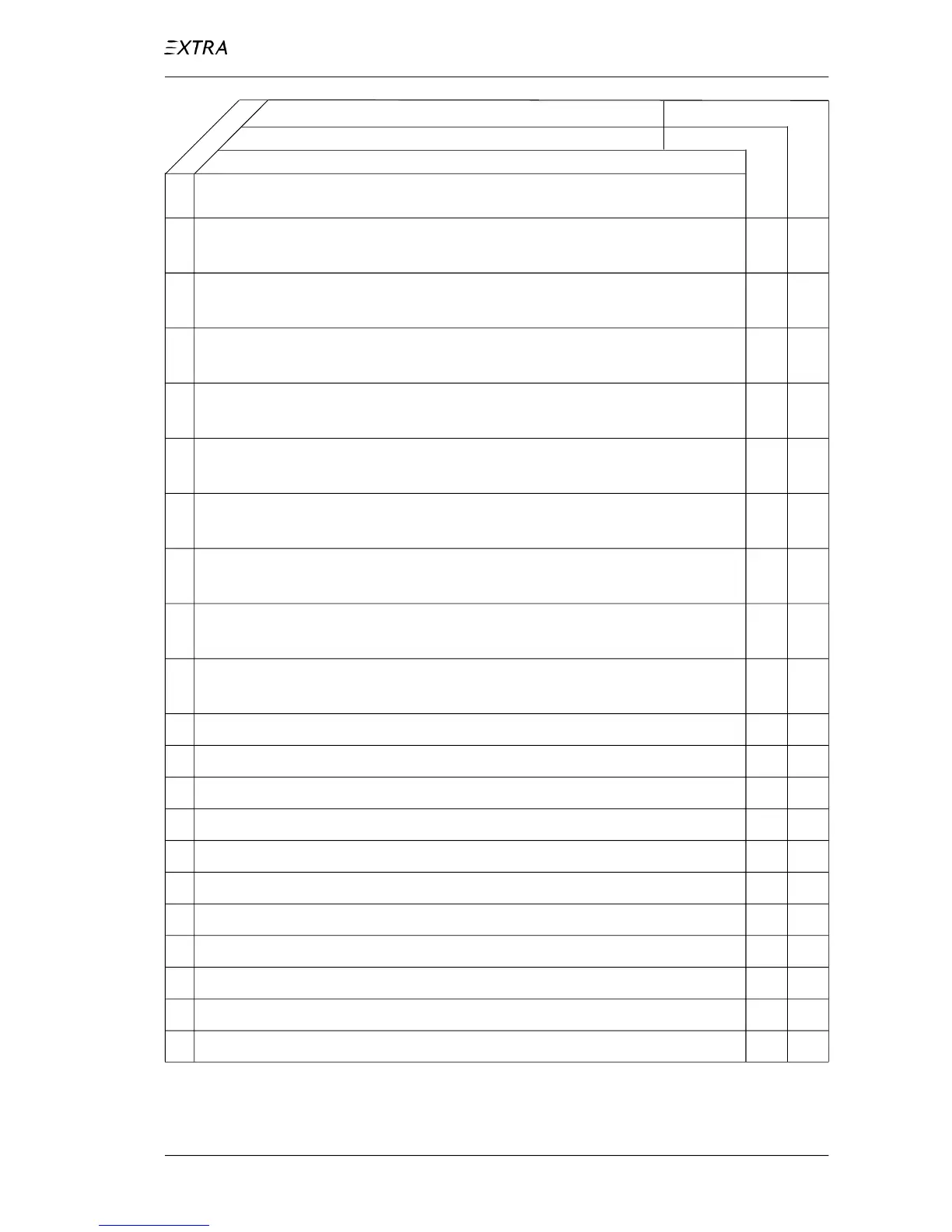

CHAPTER 5

PAGE 36

PAGE DATE: 7. July 2010

MAINTENANCE MANUAL EXTRA 300LT

Inspector:

Mechanic:

Inspections

Date:

Serial No.:

1000 hours

Hardware

O 1 Check harness attachment fittings for cracks, deformations and

corrosion.

O 2 Check bolts and nuts in critical areas for fretting, wear, damage,

stretch, proper torque and safety.

O 3 Visual inspection of tank fastening straps for cracks, damage and

corrosion.

O 4 Visually inspect tanks and tank shell for leakage. Check proper

drainage.

O 5 Visual inspection of battery fastening straps for cracks, damage and

corrosion.

O 6 Check the "quick pins" of the seat adjustment for cracks, deforma-

tions and corrosion. Inspect wear and proper function.

O 7 Visual inspection of rudder pedal mounting to the attachment

fittings. Check bolts for security.

O 8 Inspect instrument panel for cracks and damaged screw holes.

Check proper attachment and support.

O 9 Check instrument cover for dents, cracks, delamination, damaged

screw holes and tearing of edges.

Surface general

O 1 Visual check of paint for deteriorated paint.

General

O 1 Reinstall the wing as per chapter 57.

O 2 Check for security of the main spar bolts and safety-screws.

O 3 Reinstall control surfaces as per chapter 27.

O 4 Reinstall navigation/strobe lights as per chapter 33.

O 5 Reinstall wheels and brakes as per chapter 32.

O 6 Reinstall landing gear as per chapter 32.

O 7 Reinstall wheel fairings as per chapter 51.

O 8 Reinstall fuselage covers as per chapter 53.

SCHEDULED MAINTENANCE CHECKS

Significant Items Inspection

Loading...

Loading...