16

General

Device concept

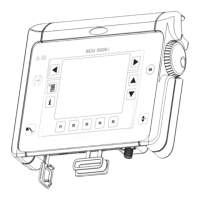

RCU 5000i remote control

The RCU 5000i remote control is intended

for the operation of all power sources in the

TransSynergic/TransPuls Synergic series.

All functions available on the power source

can be retrieved using the RCU 5000i. In

addition, further functions are available

such as optimisation of welding characteri-

stics.

Connection to the power source takes pla-

ce via a LocalNet plug.

The RCU 5000i remote control unit is

equipped with an LCD. In conjunction with

a clearly laid-out menu, this makes for a

user-friendly device.

Application areas The RCU 5000i remote control unit is used

- for operating and programming the power sources, making pre-settings,

- in robot applications,

- for manual welding using power sources equipped with the "Remote" control panel.

Advantages - Clear layout thanks to LCD

- Simple and logical operation

- 180 pre-programmed Synergic welding characteristics

- Welding characteristics can be optimised

- Easy to program jobs

- Up to 1000 jobs can be stored

- User access management using keycard

- Parameter monitoring thanks to QMaster function

- LocalNet connection

- USB interface for software updates

Standard equip-

ment

The RCU 5000i remote control unit is equipped with the following as standard:

- Connected to the remote control: 1x remote control cable, 6-pin, 5 m (16 ft. 5 in.), incl.

LocalNet plug, 10-pin

- 1x USB cable, approx. 1.8 m (5 ft. 11 in.), incl. USB adapter

- 1x memory card, 3.3 V

- 1x transponder card ("key card")

- 1x CD-ROM "software tools"

Options RCU 5000i bracket

The RCU 5000i bracket is intended for mounting on a wall or a remote power source. The

remote control unit can be hung onto the RCU 5000i bracket.

Loading...

Loading...