94

Establishing QMaster values for a selected job

General The sequence of screens shown on the "clothesline" depends on the type of job selected.

Purpose of QMas-

ter values

QMaster values can be entered individually for each job. If set QMaster values are exceed-

ed or not reached over a specific period, one of the following reactions takes place:

- Power source switches off immediately

- A warning signal is given

- No reaction

Establishing Q-

Master values for

a job

Call up the "Optimizing & managing jobs" menu item

Whatever screen is showing, select "Group n°" parameter using the down (6) or up (7)

keys

Select desired group (0 - 99) using the adjusting dial (18)

Select "Job n°" parameter using the down (6) or up (7) keys

Select desired job (0 - 999) using the adjusting dial (18)

– If a job is selected from the next group, the group displayed also changes accord-

ingly.

Select "QMaster" screen by pressing the right arrow key (8)

– "QMaster" screen appears

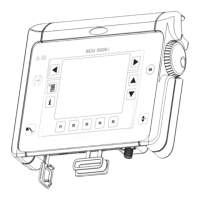

Optimizing and managing jobs: "QMaster" screen

Select the corresponding parameters

using down (6) or up (7) keys

Use the adjusting dial (18) to alter the

parameter value

– A parameter value can only be al-

tered within the defined setting

range. The setting range is high-

lighted.

1

2

3

4

5

6

7

8

NOTE! If the wirefeed speed value in the "Working parameters" screen is

changed, the values for welding current and welding voltage also change accord-

ingly, due to the synergic function.

Changes to welding current and welding voltage must be reflected in the "QMas-

ter" screen in the "current command value" and "voltage command value" param-

eters.

IMPORTANT! If the "Max. duration of voltage-deviation" and "Max. duration of current-de-

viation" parameter values are entered as "Off" in a selected job, the Q-Master function for

this job is deactivated.

Loading...

Loading...