2. Series 8 I/O Planning and Design

2.3. Series 8 I/O and C300 topology

R500 Series 8 I/O User's Guide 27

April 2017 Honeywell

Extensive self-diagnostics

Functional redundancy

Output direct/reverse

Safe-state (FAILOPT) behaviors

Each channel can be configured to HOLD LAST

VALUE, or SHED to a SAFE VALUE.

Fuse-less short circuit protection allows a short circuit to

exist without blowing any fuses. When a particular

channel is shorted, internal circuits detect this and remove

power to the field connection. The channel remains de-

energized until the short circuit is repaired.

Latched, pulsed or pulse-width modulated output

Galvanic isolation

Output read back checking to screw terminal

TC and RTD operation

Remote cold junction capability

1 sec PV scanning with OTD protection

Configurable OTD protection (See below)

Temperature points can be added in 16 point increments

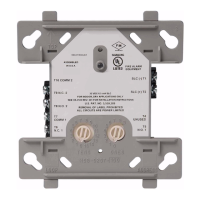

Digital Input Pulse

Accumulation module

Extensive self-diagnostics

IOM redundancy

Input direct/reverse for Digital Input channels

Internal or external field power selections

Galvanic isolation

PV processing or Pulse Accumulation functionality based

on the user configuration.

2.3 Series 8 I/O and C300 topology

Series 8 I/O is attached to an IOLINK that is being mastered by a C300 controller. It is

important to note that the IOLINK serves as data repository for IOM function blocks in

Control Builder to provide communications interface with Series 8 I/O.

Loading...

Loading...