GENERAL

The hydraulic tank requires little or no service other

than adding hydraulic oil when indicated by checking

the sight gauge and periodically cleaning the screen in

the outlet of the tank.

The hydraulic oil level should be checked daily for

proper level. Use extreme care when adding oil to

prevent the entry of contaminants.

Do not check oil level when oil is hot.

Overfilling tank could result in oil coming out cap

(breather).

If you notice the presence of water (noted by a cloudy

or milky appearance), or air (noted by a foamy appear-

ance) or other contaminants, a rancid odor (indicating

excessive heat), or after a major component failure,

the hydraulic fluid should be changed.

NOTE

The cap on the hydraulic tank is a pressure cap.

If water, air, or contamination is indicated, locate the

source of the problem and take corrective action.

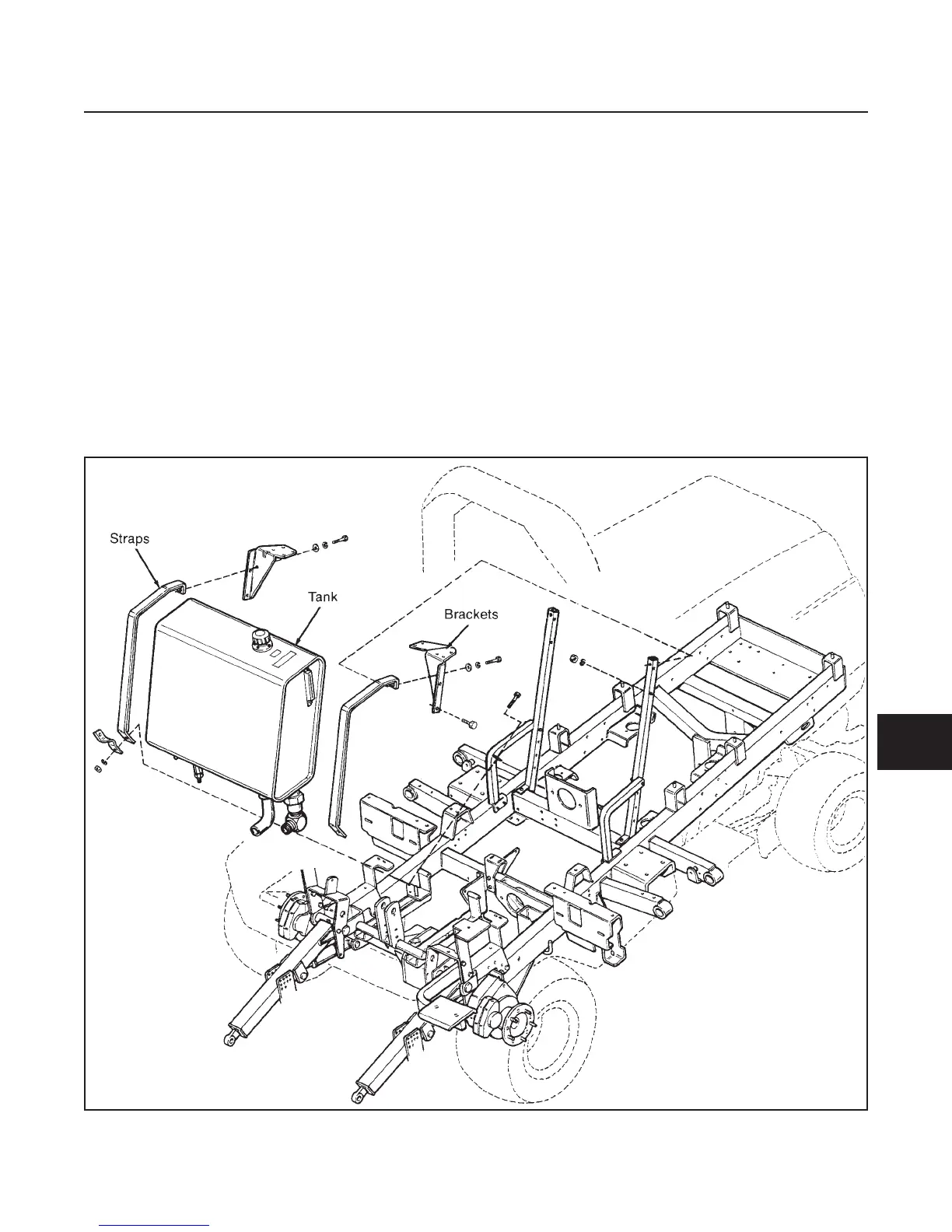

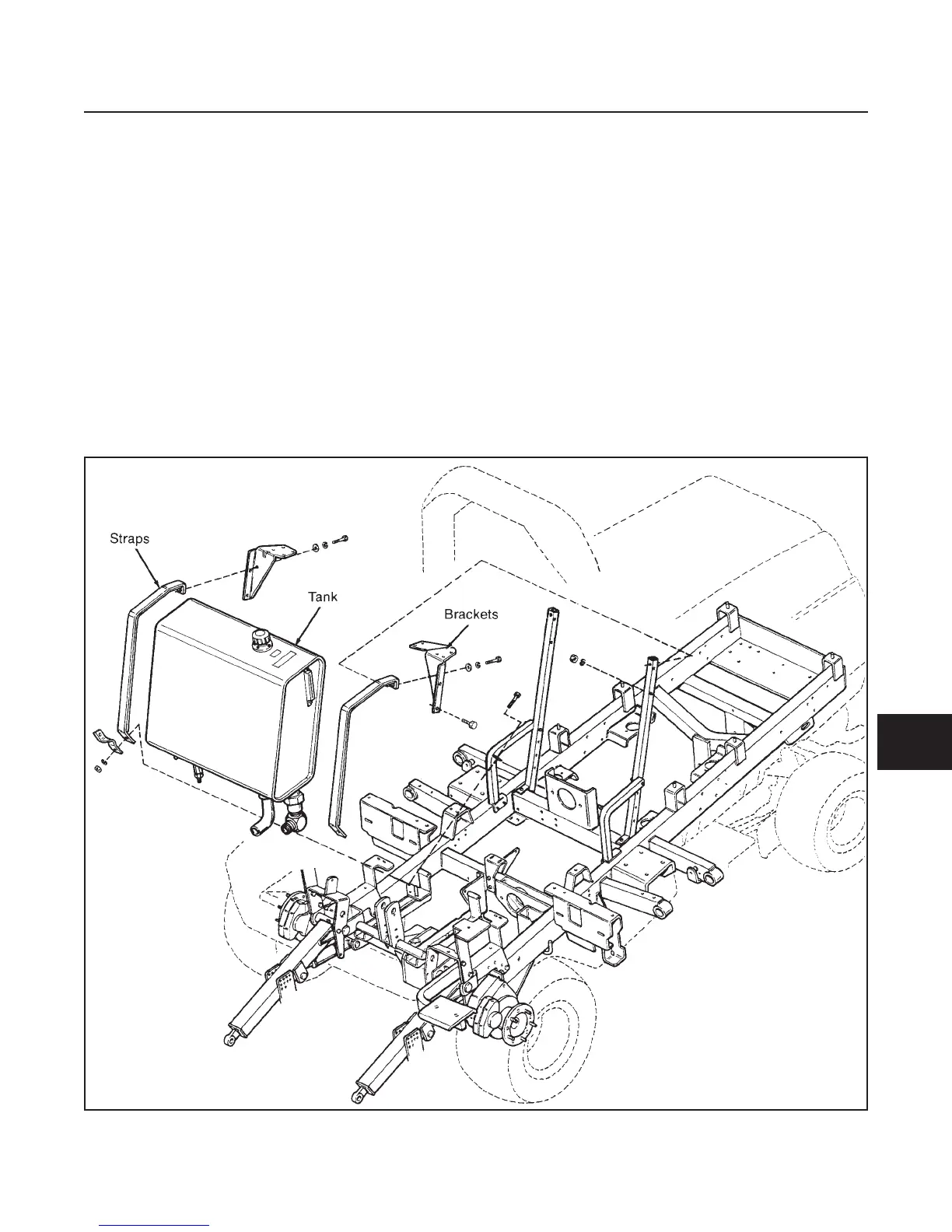

REMOVAL AND INSTALLATION

(See Figure 9D-1)

If it is necessary to remove the hydraulic tank, drain

the fluid into a suitable container, disconnect all hoses

at the tank.

When installing the hydraulic tank, secure the tank with

mounting clamps, connect hydraulic hoses to the tank.

CHASSIS

SECTION 9D. HYDRAULIC TANK

9D-1

9D

Figure 9D-1. Hydraulic Tank Removal and Installation

Loading...

Loading...