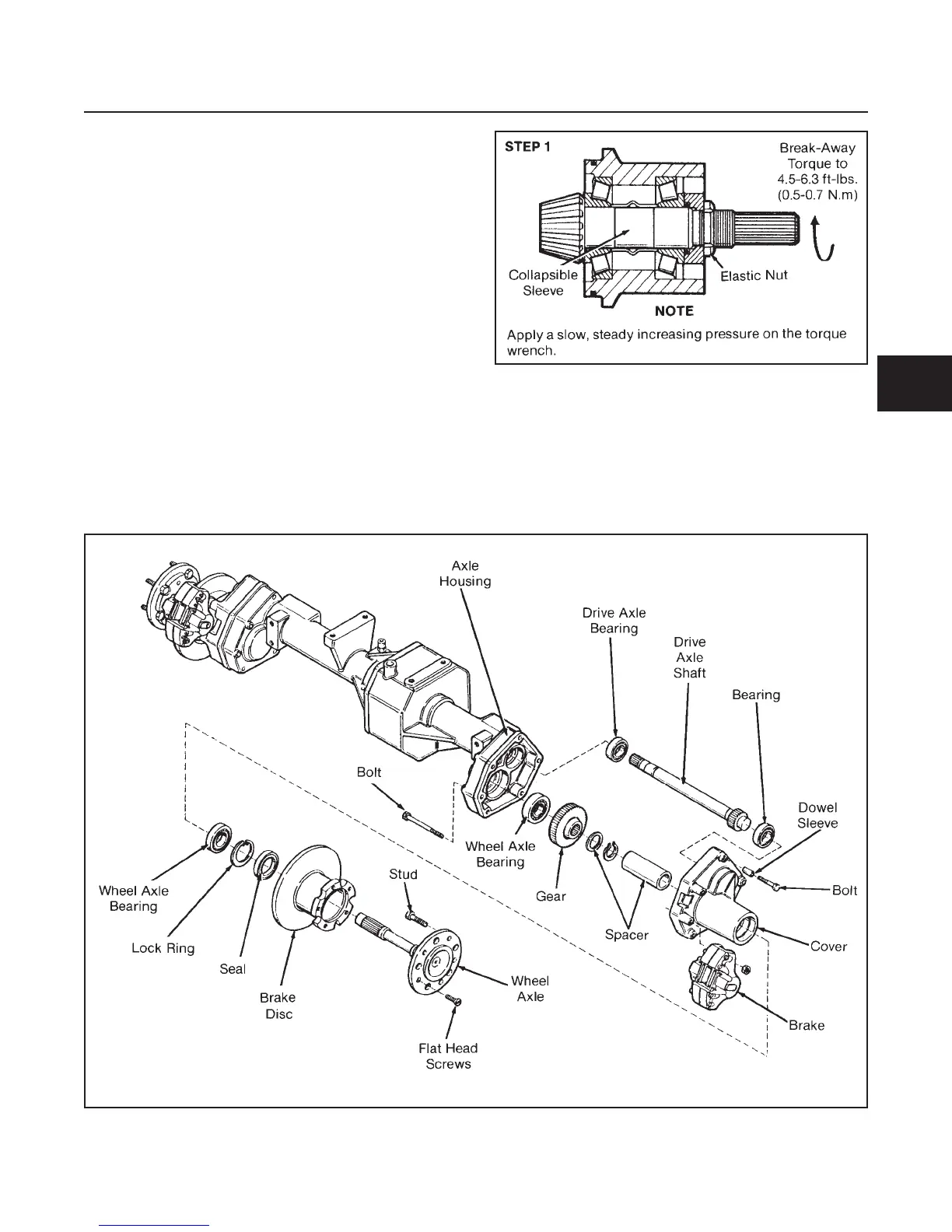

BREAK-AWAY TORQUE ADJUSTMENT

(See Figure 4E-5)

NOTE

The following adjustment is made with no seal

installed in the pinion housing.

1. Tighten the elastic nut until a break-away torque

of 4.5–6.3 in-lbs. (0.5–0.7 N.m) is obtained.

NOTE

Apply a slow steady increasing pressure on the

torque wrench.

2. Install the seal in the pinion housing.

3. Install O-ring and shims pack on pinion housing.

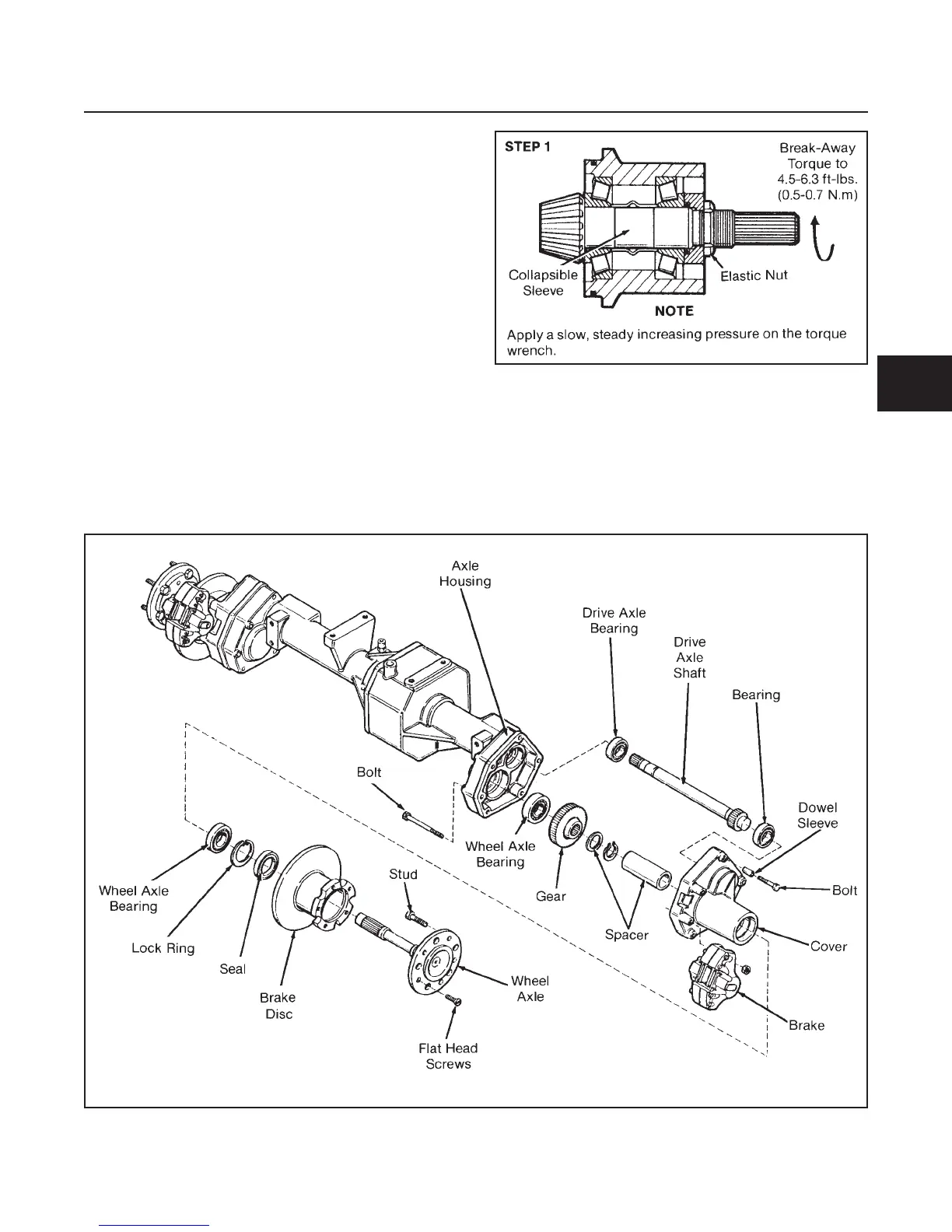

REDUCTION GEAR AND DRIVE AXLE

GENERAL

Bearings in the reduction gear case are press fitted.

The large gear is splined to the shaft. The axle pinion

gear is part of the axle shaft.

DISASSEMBLY (See Figure 4E-6)

NOTE

Remove the drive axle only if necessary.

When removing the right axle shaft the differential col-

lar will slide off the end.

DRIVE TRAIN

SECTION 4E. AXLE

4E-5

4E

Figure 4E-6. Reduction Gear and Drive Axle Disassembly

Figure 4E-5. Break-Away Torque Adjustment

Loading...

Loading...