DISASSEMBLY

1. Clean exterior of motor with suitable solvent be-

fore removing the bolts.

2. Before disassembly mark motor sections, starting

at drive shaft end, to ensure correct order and po-

sition of parts when reassembling. Recommended

method of marking body sections is to use a fine

point metal punch, making one indentation for

section #1, two indentations for section #2, etc.

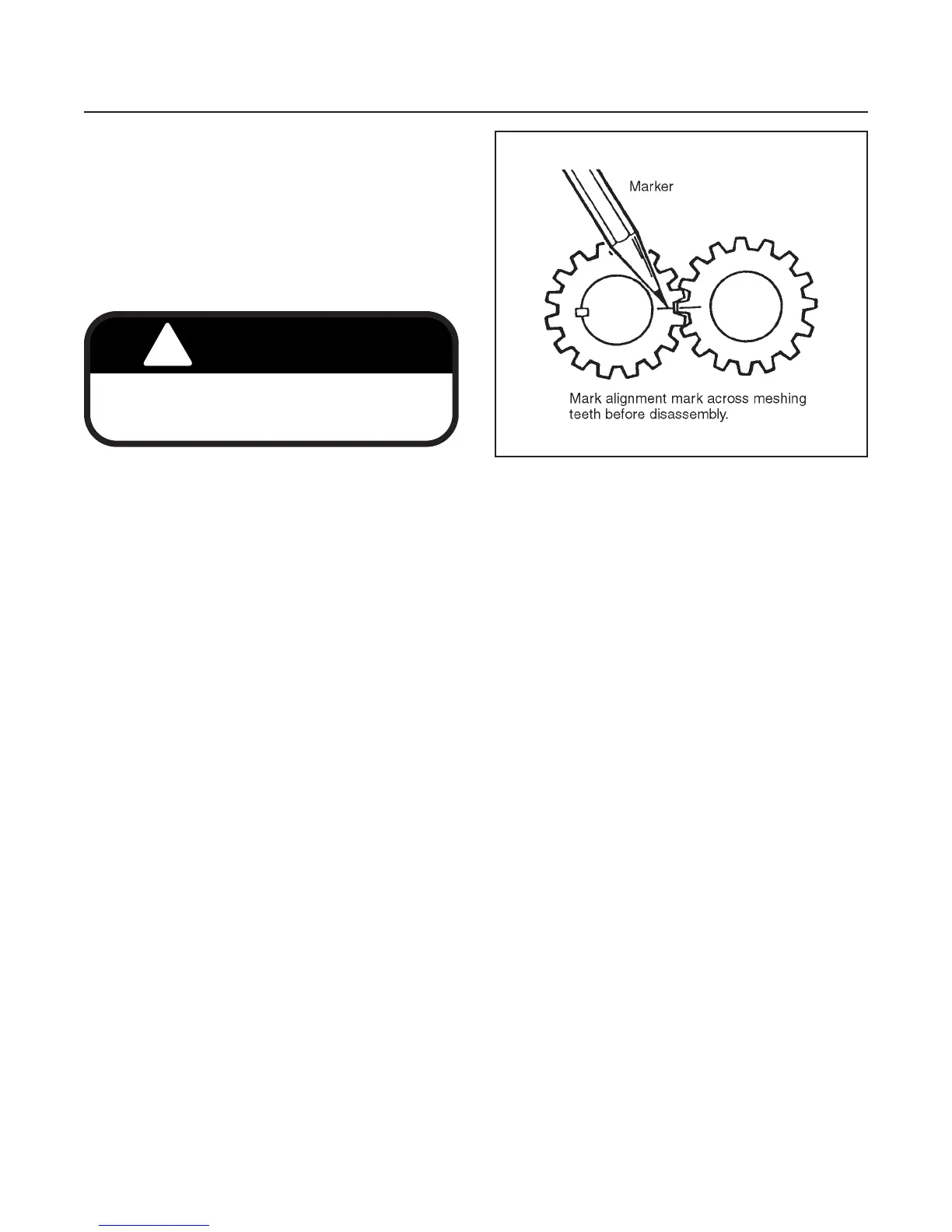

3. After removing the bolts and cover, mark a line

across meshing teeth to ensure that gears are re-

assembled in the same position (see Figure 8N-3).

4. Remove gear set.

5. Place parts in assembly order, on a clean work

area, as they are removed.

6. Discard seals as they are removed.

INSPECTION

1. Keeping parts in assembly order, clean and air dry

each for inspection. Look for metal chips or slivers

during cleaning (an indication of damage to motor

or other hydraulic component).

2. Inspect all parts for cracks, nicks, burrs and exces-

sive wear. Replace entire motor if found damaged

or worn.

REASSEMBLY (See Figure 8N-2)

1. Apply a coat of clean hydraulic oil to all parts to

ease assembly.

2. Assemble motor one section at a time, building up

from flange section.

3. Use a new seal kit during assembly. Use clean

grease to keep seals in position.

4. Remove alignment mark from gear sets after they

have been installed with teeth in mesh.

5. Rotate gear set after assembling to make sure

there is no binding between parts.

6. Install the bolts, finger tight and rotate gear set to

make sure it turns freely. Tighten tie bolts evenly

and in steps to a final torque of 26–30 ft-lbs. (35–

41 N.m).

HYDRAULICS

SECTION 8N. MOWER MOTOR

8N-2

Figure 8N-3. Marking Gear Teeth

Loading...

Loading...