GENERAL

Repair of the electrical system, for the most part, is

limited to the replacement of faulty components or wir-

ing. Wiring diagrams and Component Location illus-

trations are provided in Section 10N for troubleshoot-

ing and/or testing the electrical system. Specific repair

and replacement instructions, where applicable, are

also provided in this section.

NOTE

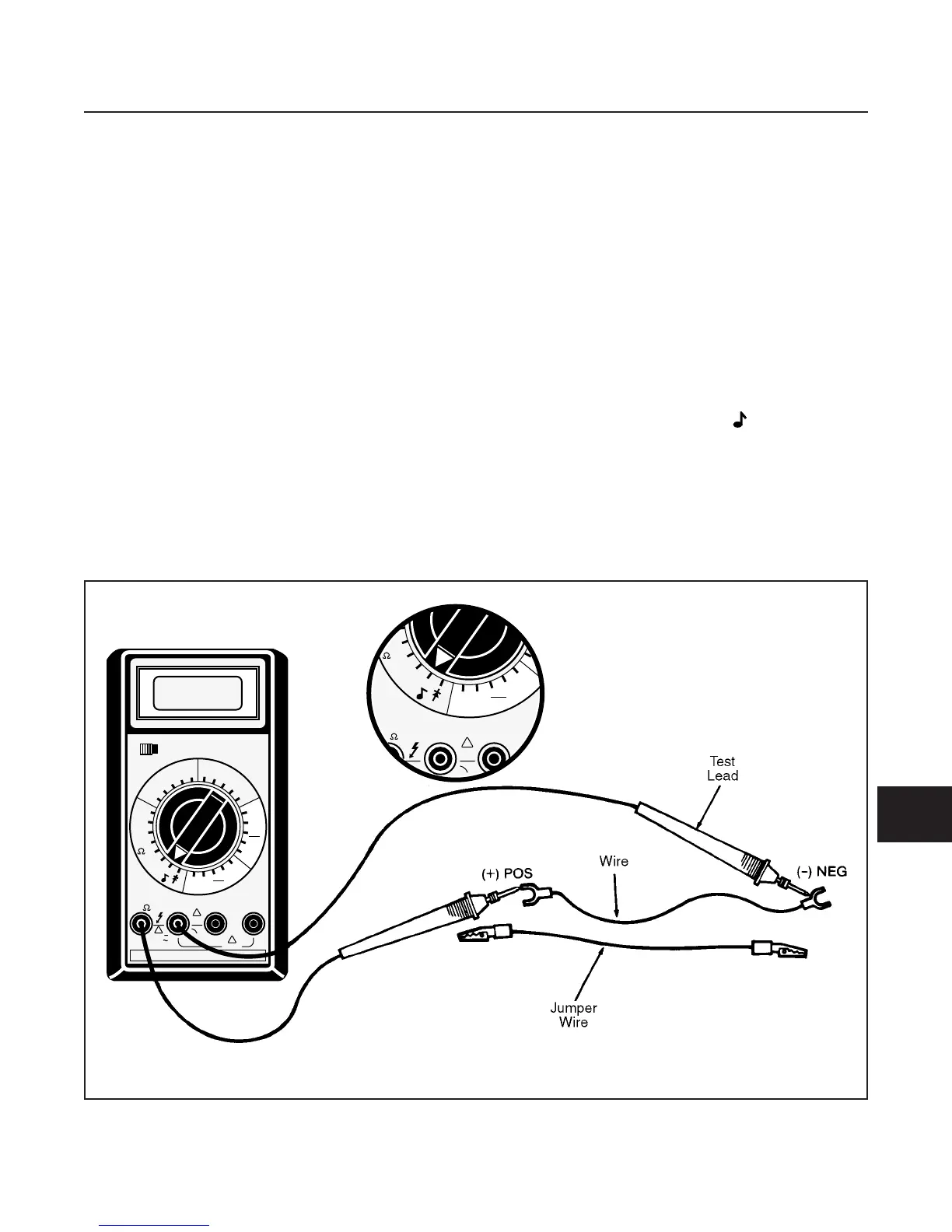

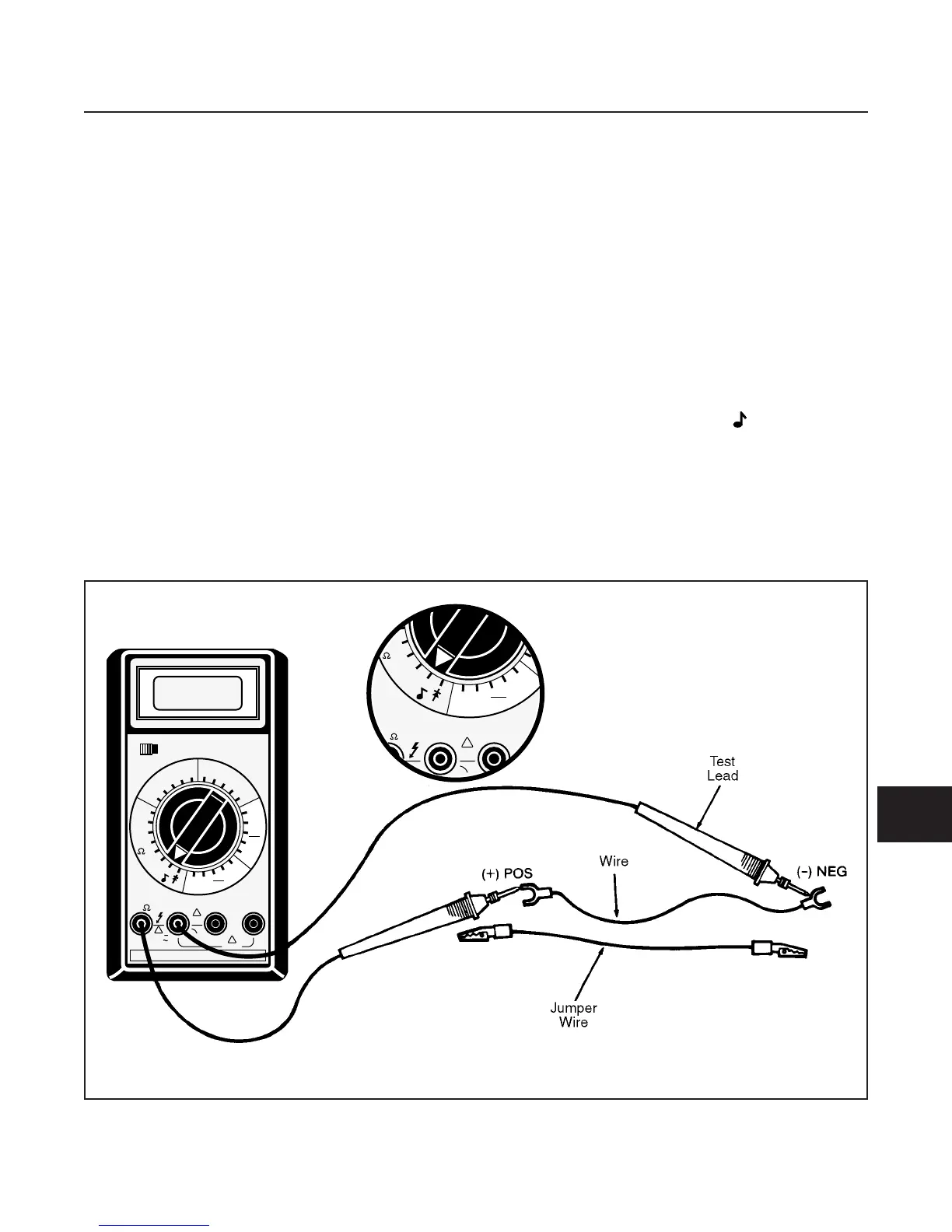

The test instrument shown in the illustrations for

this section is a digital multimeter (DMM). How-

ever, any test instrument capable of measuring

voltage, current resistance, and continuity val-

ues specified for each test is acceptable.

NOTE

See Engine Manufacturer’s Service Manual for

information on engine electrical components not

covered in this section.

In addition to testing a suspected faulty component it

may be necessary to check for shorts or breaks in the

wiring to the component. A common method of testing

wires or circuits is to perform a continuity check as

described below.

NOTE

Before performing any component or wiring test,

check for corrosion and loose or missing con-

nections.

If a component (switch, relay, etc.) is removed for test

or replacement make sure to identify and label wires

so that the component can be installed correctly.

WIRE CONTINUITY TEST

(See Figure 10C-1)

1. Identify and locate the wire to be checked on the

appropriate “Electrical System” illustration, locat-

ed in Section 10N.

2. Set multimeter to Ω (ohms) scale and touch

leads to end of wire.

•

There should be a reading (continuity) on the

multimeter. If not, proceed to 3.

3. Perform a second check by using a jumper wire to

bypass the wiring being tested. If the component

in question now functions normally, replace the

original wire.

ELECTRICAL SYSTEM

SECTION 10C. GENERAL INSTRUCTIONS

10C-1

10C

Loading...

Loading...