GENERAL

The 35 amp charging system consists of an alternator

and separate regulator.

See the Engine Manufacturer’s Service Manual for de-

tailed repairs of the alternator.

ALTERNATOR FIELD TEST

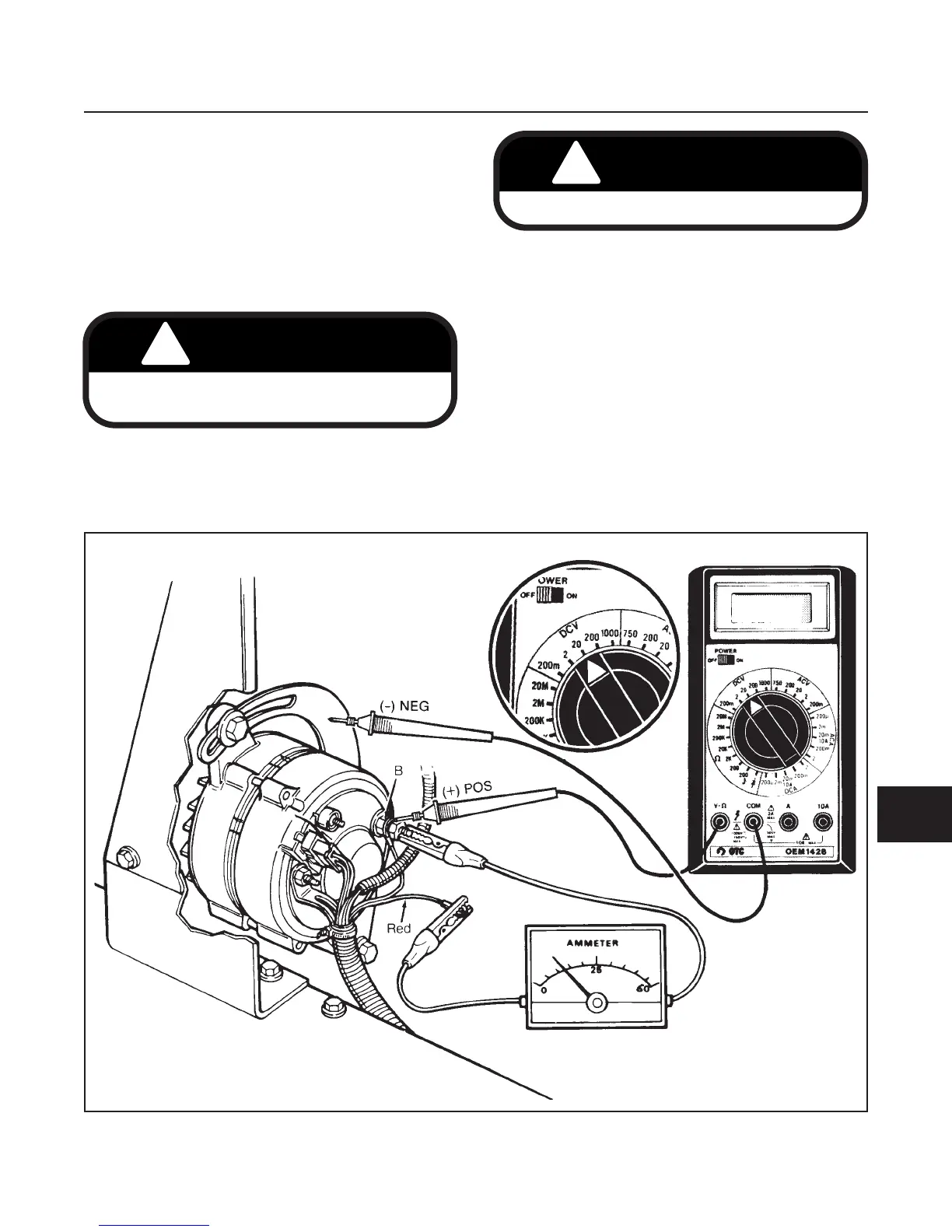

OUTPUT CURRENT (See Figure 10E-1)

1. Remove the red wire from terminal B of the alter-

nator.

2. Connect an ammeter and voltmeter as shown.

3. Start the engine.

•

As engine rpm increases, voltage should increase

to a maximum 14V at 1500 engine rpm.

•

Current output should also increase to a maxi-

mum 35 amps at 2500 engine rpm.

NOTE

Charge condition of battery will affect current

(amp) output. As the battery begins to charge,

the current output will slowly decrease.

•

If no voltage and/or current is measured, the

alternator is faulty.

ELECTRICAL SYSTEM

SECTION 10E. CHARGING SYSTEM

10E-1

10E

Before installing test instruments, disconnect the

negative battery cable from the battery.

Loading...

Loading...